Microcapsule powder containing industrial hemp protein and phosphatidylserine and preparation method of microcapsule powder

A technology of phosphatidylserine and industrial hemp, which is applied in the directions of protein-containing food ingredients, oil-containing food ingredients, polysaccharide/gum-containing food ingredients, etc., can solve the problems of low recovery rate, bitter taste, poor product solubility, etc. Long shelf life, reduced flavor loss, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1) Weigh 100 kg of deoiled industrial hemp seed meal and add it to 500 kg of 0.8mol / L sodium chloride solution, adjust the pH of the solution to 7, stir at 35°C, and stir for 2 hours.

[0040] 2) Adjust the pH of the protein solution to 8, add 0.5 kg of alkaline protease, 1 kg of flavor protease, 1 kg of complex protease, and 0.5 kg of trypsin, and keep stirring at 50°C for 3 hours.

[0041] 3) Centrifuge to remove the precipitate, and adjust the pH of the supernatant to 11.

[0042] 4) Control the temperature at 20°C, use ceramic membrane (MW: 10-500 kDa) to filter and concentrate the industrial hemp polypeptide solution, remove sugar, salt and low molecular weight polypeptides, and obtain 200 kg of industrial hemp protein polypeptide aqueous solution, and finally adjust the pH to 7. The protein content is 12.1% measured by the Kjeldahl method, the protein recovery rate is 54.8%, and the molecular weight of the industrial hemp protein polypeptide is 5000-500000Da.

Embodiment 2

[0044] 1) Add 7.5 kg of dextrin and 2.5 kg of gum arabic to 200 kg of the industrial hemp protein polypeptide aqueous solution prepared in Example 1, and stir at 50°C for 30 minutes to obtain an aqueous phase.

[0045] 2) Dissolving 7.5 kg of phosphatidylserine derived from krill oil and 0.1 kg of tea polyphenols in 5 kg of fish oil to prepare an oil phase.

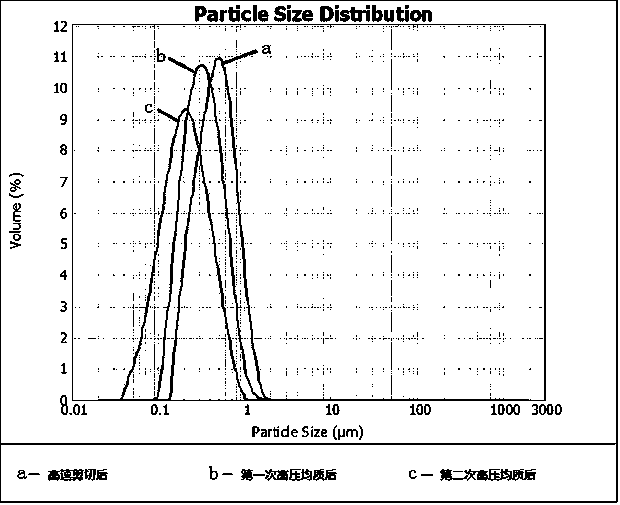

[0046] 3) Under stirring conditions, slowly add the oil phase to the water phase, high-speed shearing and stirring for 5-10 minutes, and control the liquid temperature at 50°C to obtain an oil-in-water emulsion solution, and make the fat globule size in the emulsion Less than 2μm, the particle size distribution diagram of the liquid after high-speed shearing is shown in figure 1 .

[0047] 4) The oil-in-water emulsion solution is subjected to high-pressure homogenization treatment, and the pressure is 25MPa. The high-pressure homogenization is performed twice. The particle size distribution of the liquid after homogenizat...

Embodiment 3

[0049] 1) Add 200 kg of the industrial hemp protein polypeptide aqueous solution prepared in Example 1 to 10 kg of dextrin and stir at 50°C for 30 minutes to obtain the aqueous phase.

[0050] 2) 5 kg of soybean-derived phosphatidylserine and 0.1 kg of vitamin E were dissolved in 7.5 kg of linseed oil to prepare an oil phase.

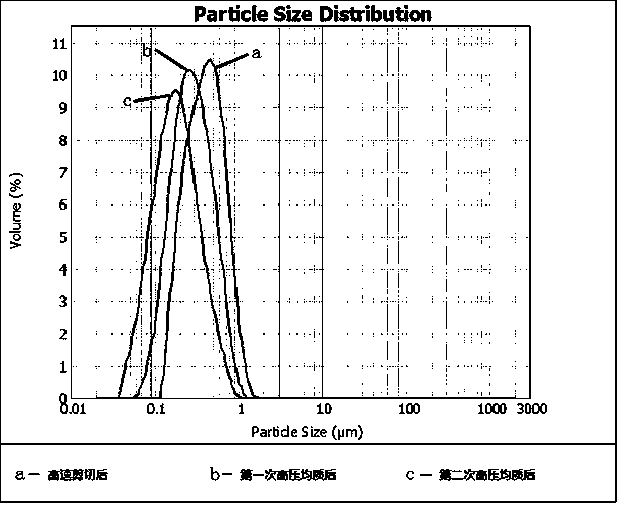

[0051] 3) Under stirring conditions, slowly add the oil phase into the water phase, stir at high speed for 5-10 minutes, and control the liquid temperature at 50°C to obtain an oil-in-water emulsion solution. And the particle size of the fat globules in the emulsion is less than 2 μm, and the particle size distribution diagram of the liquid after high-speed shearing is shown in figure 2 .

[0052] 4) The oil-in-water emulsion solution is subjected to high-pressure homogenization treatment, and the pressure is 25MPa. The high-pressure homogenization is performed twice. The particle size distribution of the liquid after homogenization is shown in figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com