A degradable, anti-adhesion double-layer dura mater patch and its preparation method

A dura mater and anti-adhesion technology, applied in prostheses, products, educts, etc., can solve the problems of immune rejection, loss of effective active ingredients, limited dura mater regeneration ability, etc., and achieve the effect of a simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

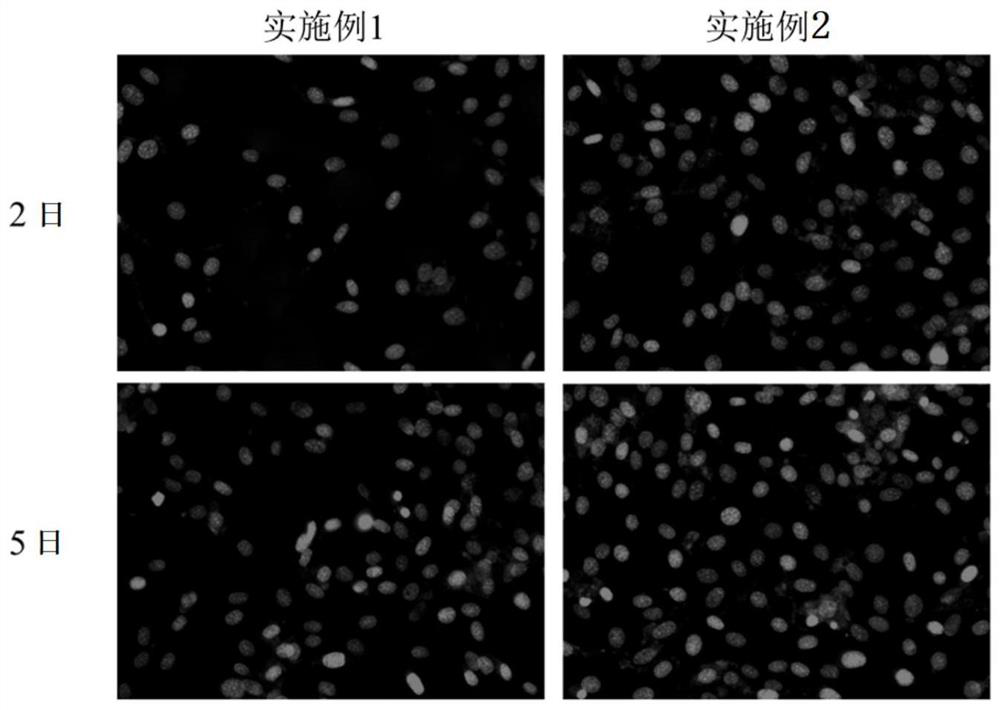

Embodiment 1

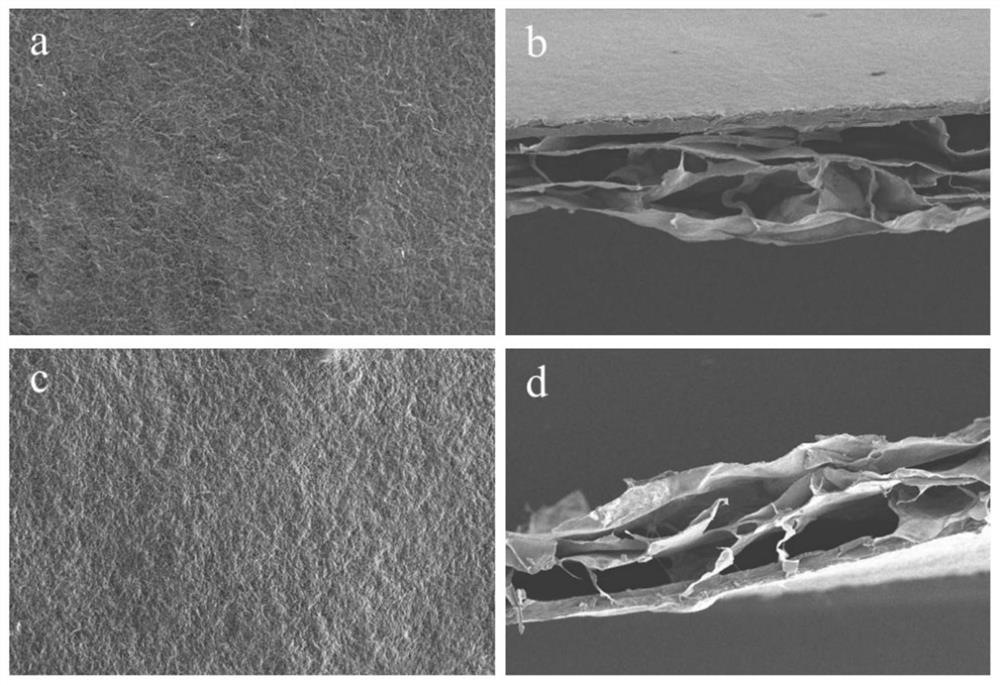

[0064] A method for preparing a degradable, anti-adhesion double-layer dura mater patch, comprising the following steps:

[0065] 1) Preparation of dense layer by horizontal casting method

[0066] High molecular weight chitosan powder (deacetylation degree is 85%, viscosity-average molecular weight is 0.85×10 6 ) into 2% (v / v) acetic acid solution, stirring and dissolving at room temperature to obtain 1.5wt.% chitosan acetic acid solution. Add bacterial cellulose dispersion in a preferred ratio, stir evenly and filter to remove undissolved impurities, vacuum defoam until no bubbles are generated within 2 minutes, and obtain a 0.5wt.% chitosan / bacterial cellulose mixed solution. The above mixed solution was poured into a high borosilicate petri dish with a diameter of 90mm, and dried overnight in a blast oven at 60°C. After returning to normal temperature, pour 1mol / L sodium hydroxide solution to release the mold and neutralize excess acetic acid, then wash the film with pur...

Embodiment 2

[0077] A method for preparing a degradable, anti-adhesion double-layer dura mater patch, comprising the following steps:

[0078] 1) Preparation of dense layer by horizontal casting method

[0079] High molecular weight chitosan powder (deacetylation degree is 85%, viscosity-average molecular weight is 0.85×10 6 ) into 2% (v / v) acetic acid solution, stirring and dissolving at room temperature to obtain 1.5wt.% chitosan acetic acid solution. Add bacterial cellulose dispersion in a preferred ratio, stir evenly and filter to remove undissolved impurities, vacuum defoam until no bubbles are generated within 2 minutes, and obtain a 0.5wt.% chitosan / bacterial cellulose mixed solution. The above mixed solution was poured into a high borosilicate petri dish with a diameter of 90mm, and dried overnight in a blast oven at 60°C. After returning to normal temperature, pour 1mol / L sodium hydroxide solution to release the mold and neutralize excess acetic acid, then wash the film with pur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com