Molecular chain self-spinning fluorine-containing UV resin and preparation method thereof

A self-rotation and molecular chain technology, applied in the field of molecular chain self-rotation type fluorine-containing UV resin and its preparation, can solve the problems of complex process, weak substrate adhesion, low fluorine content, etc. Speed, effect of high fluorine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

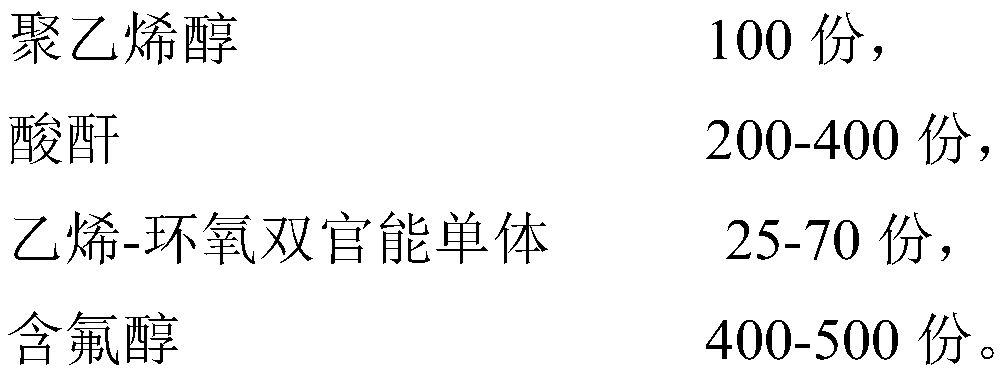

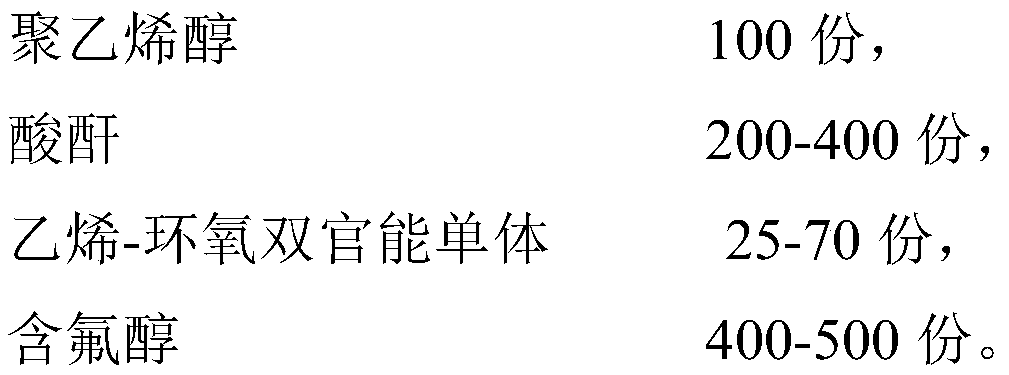

[0029] Weigh 100 g of polyvinyl alcohol, 200 g of maleic anhydride, 25 g of glycidyl acrylate, and 400 g of octafluoropentanol.

[0030] Put polyvinyl alcohol and maleic anhydride into the reaction kettle, slowly raise the temperature to 50°C, and dissolve.

[0031] Raise the temperature to 80°C, react for 5 hours, measure the acid value of the reaction system, when the acid value reaches 280KOH / (mg / g), the reaction ends.

[0032] Slowly put glycidyl acrylate into the reaction kettle, and the feeding time is 1 hour.

[0033] Raise the temperature to 80°C, keep the temperature for 5 hours, and measure the acid value of the system. When the acid value reaches 200KOH / (mg / g), the reaction ends.

[0034] Slowly put octafluoropentanol into the reaction kettle for 1 hour.

[0035] Raise the temperature to 100°C, fill with nitrogen, keep the temperature for 5 hours, and measure the acid value of the reaction system. When the acid value is 0.4KOH / (mg / g), the reaction ends.

Embodiment 2

[0037] Weigh 100 g of polyvinyl alcohol, 400 g of methyl hexahydrophthalic anhydride, 70 g of glycidyl methacrylate, and 500 g of hexafluorobutanol.

[0038] Put polyvinyl alcohol and methyl hexahydrophthalic anhydride into the reaction kettle, slowly raise the temperature to 60°C, and dissolve.

[0039] Raise the temperature to 90°C, react for 3 hours, measure the acid value of the reaction system, when the acid value reaches 300KOH / (mg / g), the reaction ends.

[0040] Slowly put glycidyl methacrylate into the reaction kettle for 2 hours.

[0041] Raise the temperature to 90°C, keep the temperature for reaction for 3 hours, measure the acid value of the system, when the acid value reaches 230KOH / (mg / g), the reaction ends.

[0042] Slowly pour hexafluorobutanol into the reactor for 2 hours.

[0043] Raise the temperature to 120° C., fill with nitrogen, and keep the temperature for 3 hours to react. Measure the acid value of the reaction system. When the acid value is 2.8 KOH / ...

Embodiment 3

[0045] Weigh 100 g of polyvinyl alcohol, 400 g of methyltetrahydrophthalic anhydride, 35 g of glycidyl methacrylate, and 450 g of hexafluorobutanol.

[0046] Put polyvinyl alcohol and methyl tetrahydrophthalic anhydride into the reaction kettle, slowly raise the temperature to 60°C, and dissolve.

[0047] Raise the temperature to 90°C, react for 3 hours, measure the acid value of the reaction system, when the acid value reaches 290KOH / (mg / g), the reaction ends.

[0048] Slowly put glycidyl methacrylate into the reaction kettle, and the feeding time is 2 hours.

[0049] Raise the temperature to 90°C, keep the temperature for 3 hours, and measure the acid value of the system. When the acid value reaches 220KOH / (mg / g), the reaction ends.

[0050] Slowly pour hexafluorobutanol into the reactor for 2 hours.

[0051] Raise the temperature to 120°C, fill with nitrogen, keep the temperature for 3 hours, and measure the acid value of the reaction system. When the acid value is 1.4KOH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com