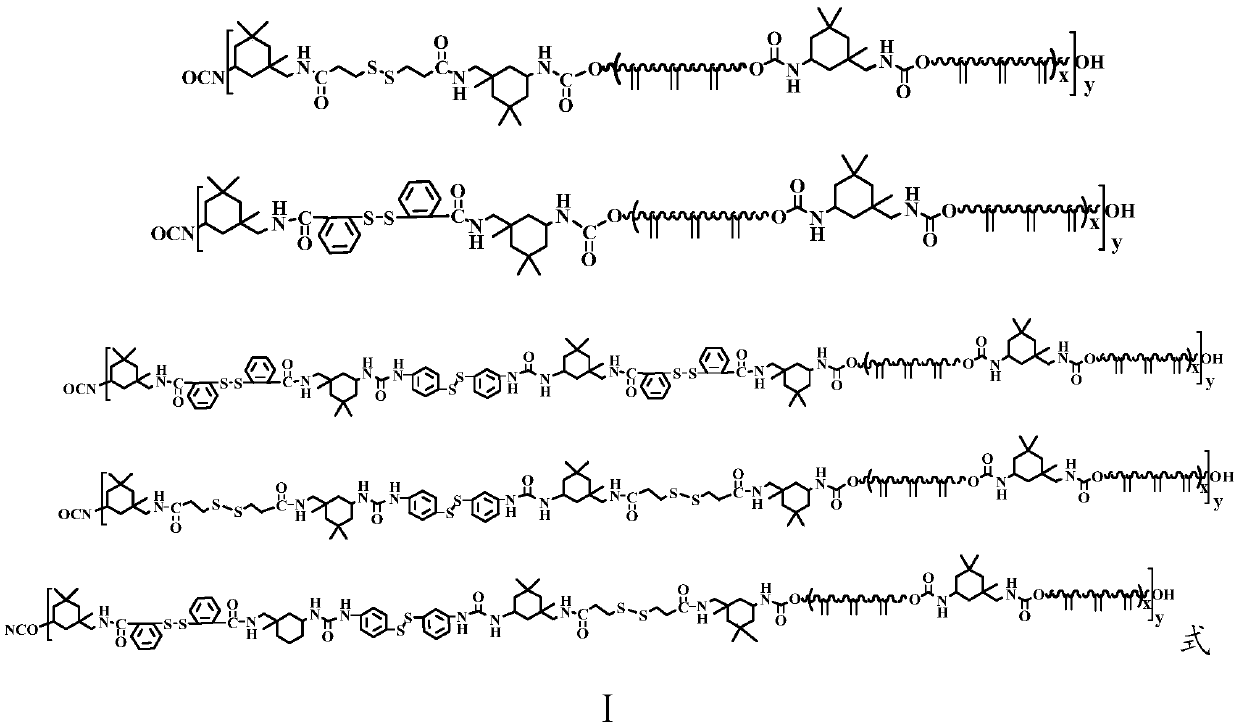

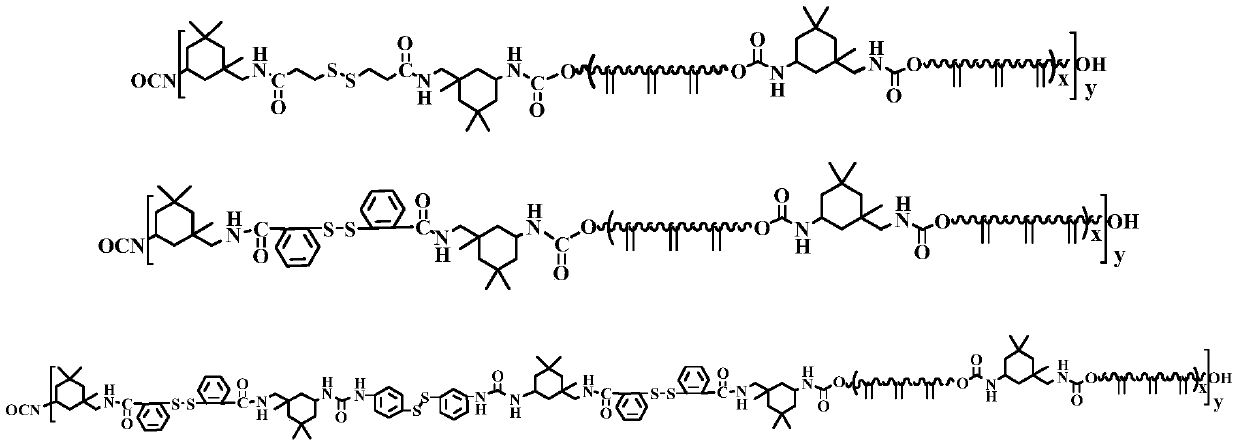

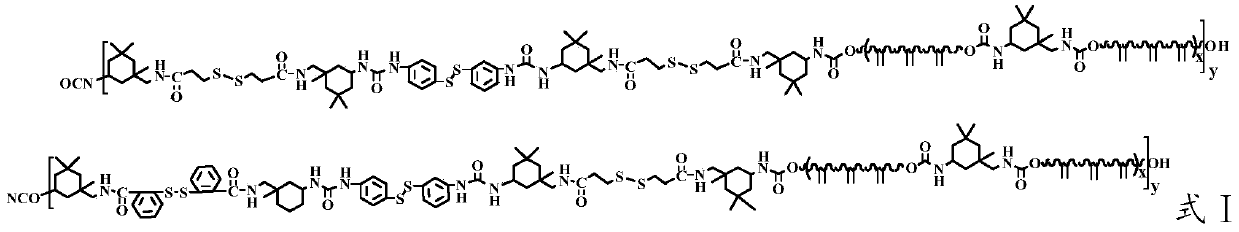

Self-repairing polyurethane based on hydrogen bonds and dynamic disulfide bonds as well as preparation method and application of self-repairing polyurethane

A disulfide bond and polyurethane technology, which is applied in the field of polymer preparation, can solve the problems of polyurethane's difficult mechanical strength and self-repair cycle, and achieve multiple self-repair functions, low repair temperature, and novel preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a method for preparing polyurethane with self-repairing function, comprising:

[0040] Prepolymers containing isocyanate groups and dynamic disulfide bonds and polyamino (butylene itaconate-co-butylene succinate) (PU-BIS) are used as raw materials for polymerization reactions. After the reaction is complete, Cross-linking by mercapto-ene click reaction to form a thin film.

[0041] The self-healing performance and mechanical strength of the cross-linked film and the molar ratio of disulfide in the prepolymer and the polyamino(butylene itaconate-co-butylene succinate) (PU-BIS) The hydrogen bond content is related, so the present invention is preferred, (3,3-dithiodipropionic acid+dithiosalicylic acid):4,4-diaminodiphenyl disulfide=1:0.5~1;3 , 3-dithiodipropionic acid: dithiosalicylic acid = 0:1 ~ 1:0; low molecular weight unsaturated polyester: isophorone diisocyanate = 1: 0 ~ 0.9.

[0042] Existing studies have shown that compared w...

Embodiment 1

[0064] Put isophorone diisocyanate and PBIS-2000 with a molar ratio of 2:1 in a 250ml four-neck flask, use chloroform solution as a solvent, and dibutyltin dilaurate as a catalyst, the amount of which is the quality of PBIS-2000 0.05%, connected with spherical condenser, thermometer and stirrer, heated up to 70°C under nitrogen protection and stirred, and reacted for 3 hours. Then, slowly drop PBIS-2000 into the flask, the molar ratio of the added amount to isophorone diisocyanate is 1:1, and add the catalyst dibutyltin dilaurate, the added amount is 0.05% of the mass of PBIS-2000, Under nitrogen protection, the reaction was continued for 3 hours. The hydroxyl-terminated unsaturated polyurethane PU-BIS-2000 was obtained.

[0065] 3,3-dithiodipropionic acid, 4,4-diaminodiphenyl disulfide and isophorone diisocyanate with a molar ratio of 1:0.5:2 were placed in a 250ml four-neck flask, and the chloroform solution As a solvent, connect a spherical condenser, a thermometer and a ...

Embodiment 2

[0067]Put isophorone diisocyanate and PBIS-2000 with a molar ratio of 1:2 in a 250ml four-neck flask, use chloroform solution as a solvent, and dibutyltin dilaurate as a catalyst, the amount of which is the quality of PBIS-2000 0.05%, connected with spherical condenser, thermometer and stirrer, heated up to 70°C under nitrogen protection and stirred, and reacted for 3 hours. Then, slowly drop isophorone diisocyanate into the flask, the molar ratio of the amount added to PBIS-2000 is 1:1, and the catalyst dibutyltin dilaurate is added, the amount added is 0.05% of the mass of PBIS-2000, Under nitrogen protection, the reaction was continued for 3 hours. Next, slowly drop PBIS-1000 into the flask, the molar ratio of the amount added to PBIS-2000 is 1:1, and add the catalyst dibutyltin dilaurate, the amount added is 0.05% of the mass of PBIS-1000, under nitrogen Under protection, the reaction was continued for 3 hours. The hydroxyl-terminated unsaturated polyurethane PU-BIS-1000...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com