Negative electrode active material for non-aqueous electrolyte secondary battery and method for producing same

A technology of negative electrode active material and non-aqueous electrolyte, which is applied in the field of negative electrode active material for non-aqueous electrolyte secondary battery and its preparation, so as to improve cycle characteristics and initial charge and discharge efficiency, improve initial efficiency, and easy to assemble and disassemble. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

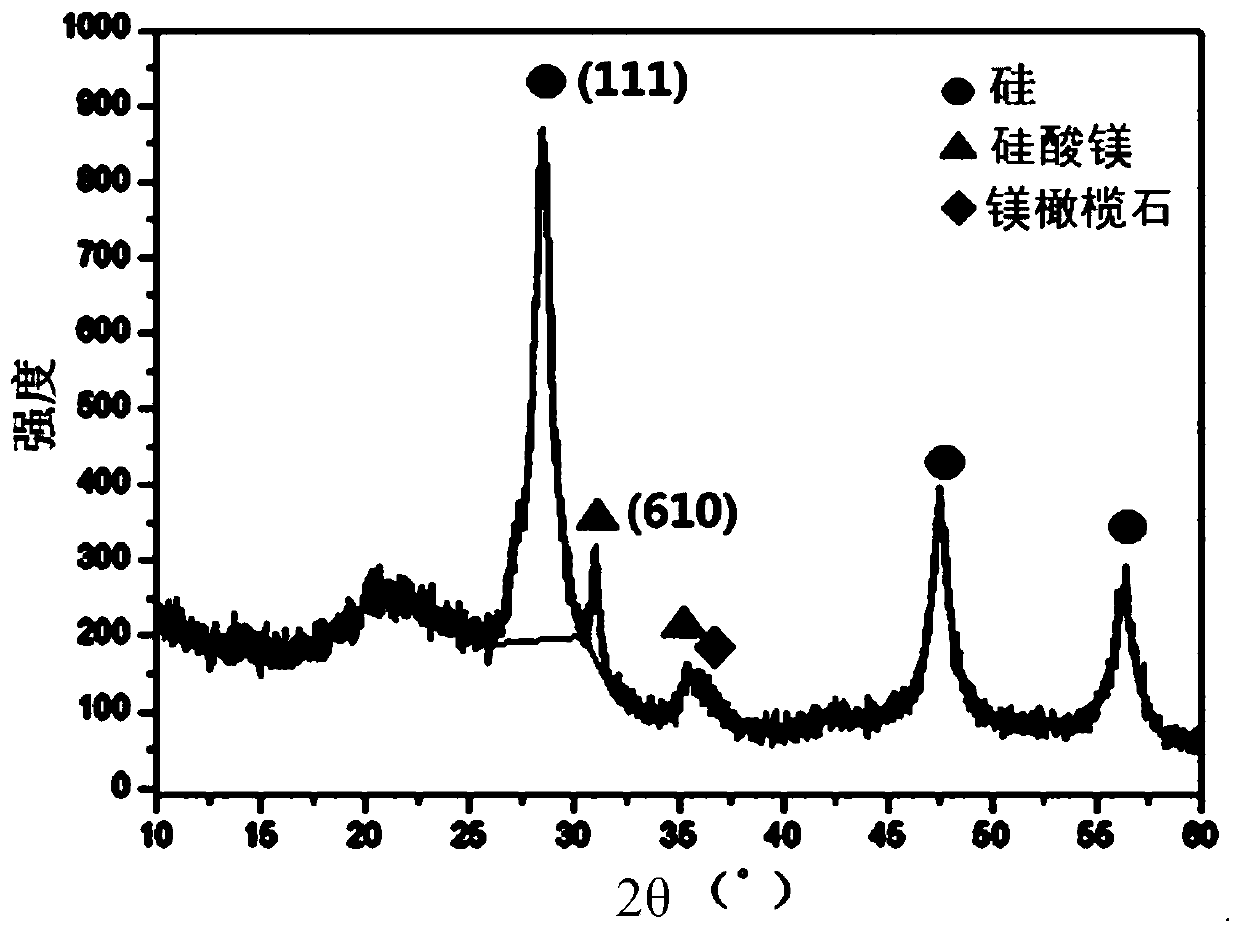

[0045] Example 1. Preparation of silicon oxide composites containing magnesium

[0046] Heat-treat 15kg of silicon powder and silicon dioxide (SiO 2 ) powder powder and 1.5kg of magnesium, the above silicon, silicon dioxide (SiO 2 ) of the mixed powder of silicon oxide vapor and magnesium vapor are simultaneously generated to react in the gas phase, cooled at a temperature of 700°C and then precipitated, and then crushed and classified with a jet mill to obtain an average particle size (D 50 ) is magnesium-silicon oxide composite powder of 6.3 μm.

[0047] In order to form a carbon-containing coating layer, the recycled silicon oxide composite powder containing magnesium is placed in argon (Ar) and methane (CH 4 ) in a mixed gas, and processed by chemical vapor deposition (CVD) for 2 hours to prepare a silicon oxide composite (sample 1).

[0048] It was confirmed from the above silica composite (sample 1) containing magnesium that the BET specific surface area was 6.2m 2 ...

Embodiment 2

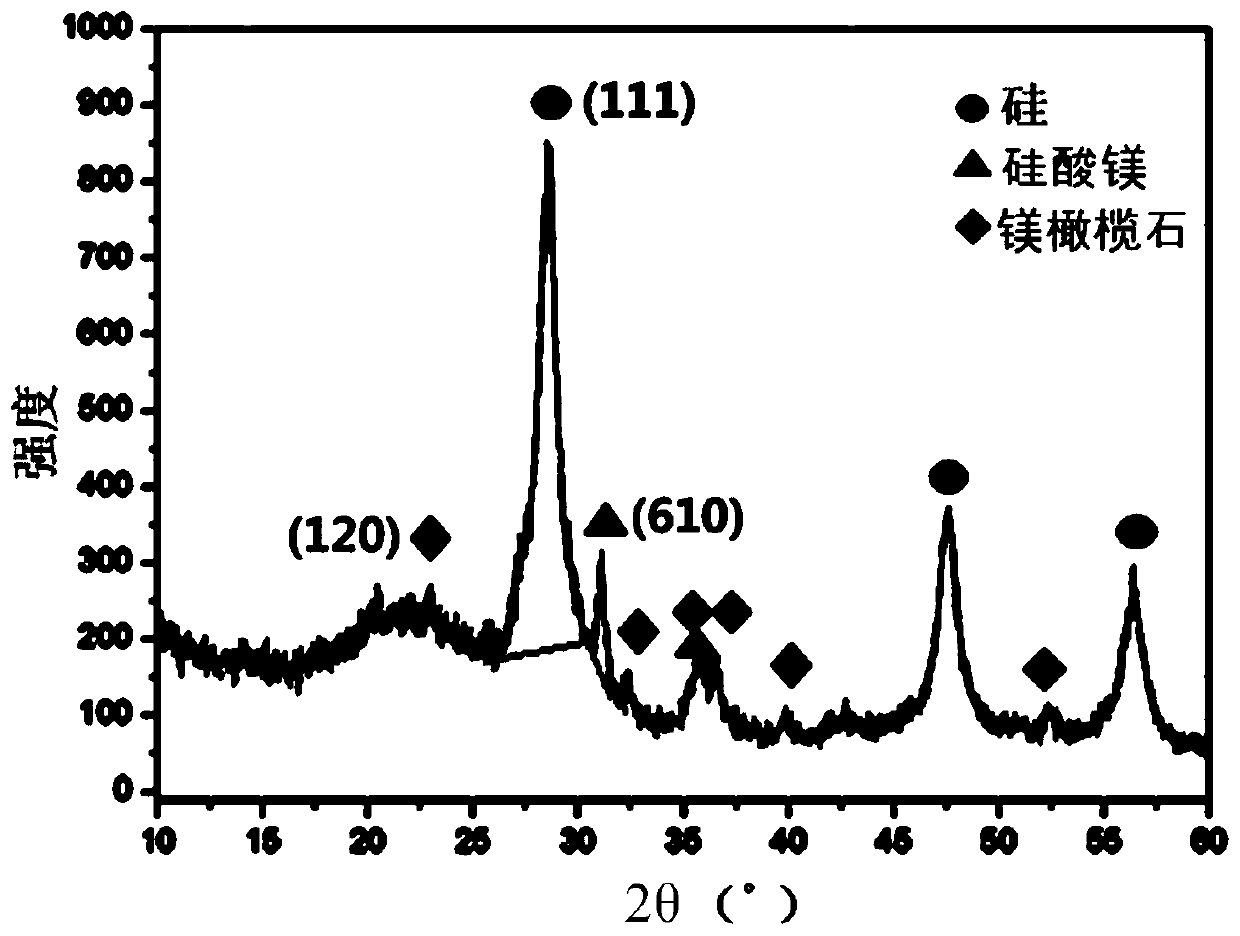

[0049] Example 2. Preparation of silica composites containing magnesium

[0050] Except for precipitation after cooling at a temperature of 800°C, a silicon oxide composite containing 9% by weight of magnesium was prepared by the same method as in Example 1 above, and a carbon coating layer with a carbon content of 5% by weight was formed. SiO composite powder.

[0051] It was confirmed from the above silica composite (sample 2) containing magnesium that the BET specific surface area was 6.3m 2 / g, the specific gravity is 2.3g / cm 3 , average particle size (D 50 ) was 6.2 μm, and the size of silicon crystals measured by X-ray diffraction analysis (CuKα) was 8 nm.

Embodiment 3

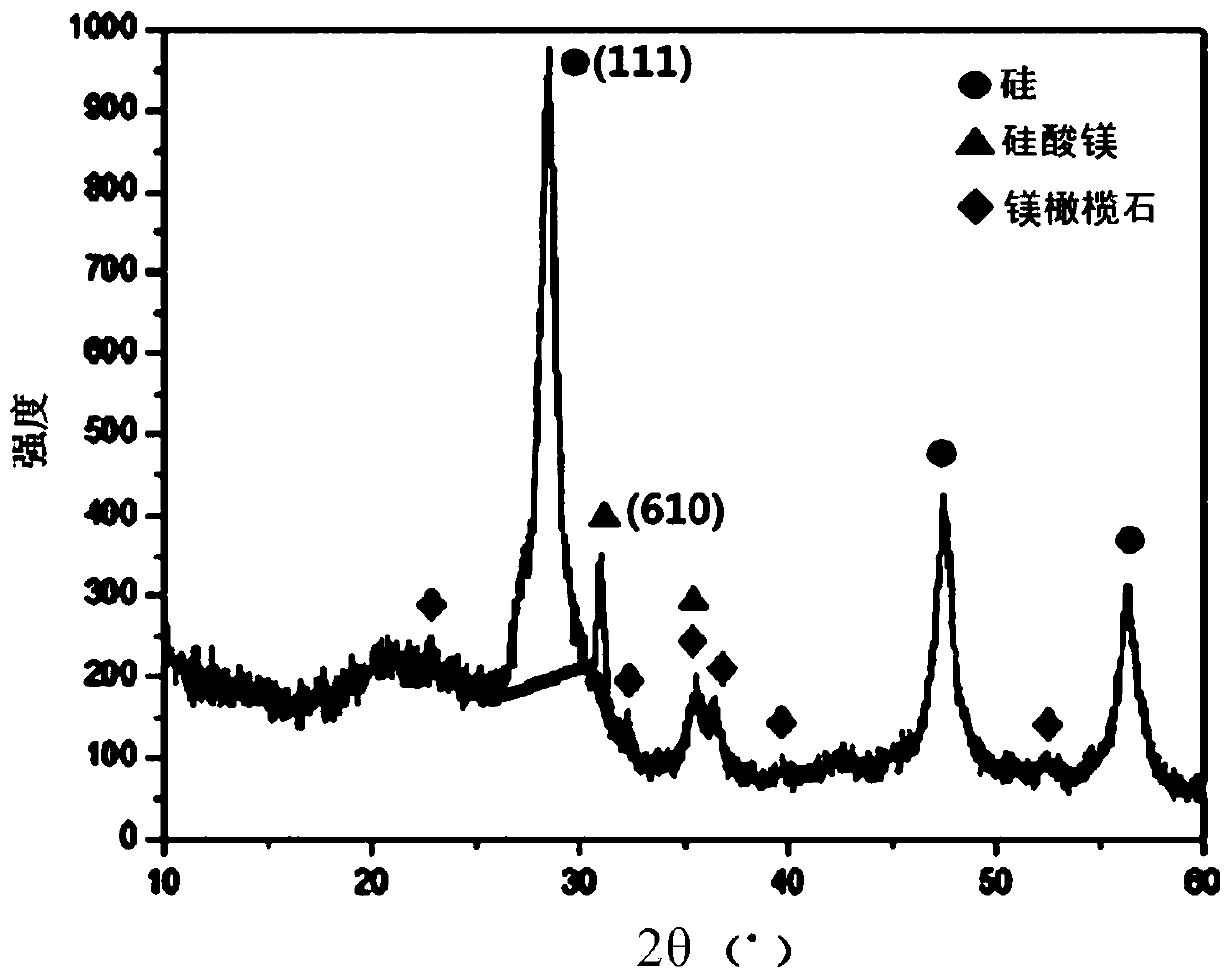

[0052] Example 3. Preparation of silica composites containing magnesium

[0053] A silicon oxide composite containing 11.7% by weight of magnesium was prepared by the same method as in Example 1 above, except that precipitation was carried out after cooling at a temperature of 900° C., and a carbon coating with a carbon content of 10% by weight was prepared. layer of silicon oxide composite powder (sample 3).

[0054] It was confirmed from the above silica composite (sample 3) containing magnesium that the BET specific surface area was 5.8 m 2 / g, the specific gravity is 2.4g / cm 3 , average particle size (D 50 ) was 6.7 μm, and the size of silicon crystals measured by X-ray diffraction analysis (CuKα) was 11 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com