Urea modified carbon nanotube well cementation cement paste and preparation method thereof

A technology of cementing cement slurry and modified carbon, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of limited reaction yield, many reaction steps, complicated process, etc., and achieve the reduction of steps and mechanical properties The effect of enhancing and increasing the reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of urea modified carbon nanotube:

[0026] (1) Take 1 part of carbon nanotubes, add 10 parts of concentrated sulfuric acid and 30 parts of nitric acid in sequence, and mix to obtain solution A; ultrasonically treat solution A at 140-150°C for 3 hours, and then use 20% hydrogen peroxide The aqueous solution was treated for 2-3 hours, centrifuged, washed with distilled water until neutral, suction filtered and dried to obtain solid S;

[0027] (2) Add 20 parts of acetonitrile and 1.2 parts of EDCI sequentially to the solid S obtained in step (1) to obtain a mixed solution B;

[0028] (3) Add 1.2 parts of urea and 2 parts of triethylamine to the mixed solution B obtained in step (2), stir at room temperature for 2 hours, filter, remove the solvent by rotary evaporation, recover the black solid at the bottom, rinse with deionized water, drying to obtain urea-modified carbon nanotubes.

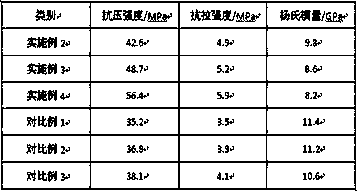

Embodiment 2

[0030] The preparation method of urea modified carbon nanotube is the same as embodiment 1;

[0031] A urea-modified carbon nanotube cementing slurry, which is composed of the following raw materials in parts by weight: 100 parts of oil well cement, 1.5 parts of fluid loss reducer, 0.02 part of urea-modified carbon nanotube, 0.1 part of defoamer and 44 parts of clear water share;

[0032] The oil well cement is grade G oil well cement;

[0033] The fluid loss reducing agent is cellulose derivatives, specifically but not limited to carboxymethyl cellulose, hydroxyethyl cellulose or carboxymethyl hydroxyethyl cellulose;

[0034] The main component of the defoamer is polyethylene glycol;

[0035] A preparation method of urea modified carbon nanotube cement slurry, comprising the following steps:

[0036] (1) Mix oil well cement and fluid loss reducer to obtain solid mixture A;

[0037] (2) Take clean water, urea-modified carbon nanotubes and defoamer, mix them, and ultrasonic...

Embodiment 3

[0040] The preparation method of urea modified carbon nanotube is the same as embodiment 1;

[0041] A urea-modified carbon nanotube cementing slurry, which is composed of the following raw materials in parts by weight: 100 parts of oil well cement, 1 part of fluid loss reducer, 0.04 part of urea-modified carbon nanotube, 0.2 part of defoamer and 44 parts of clear water share;

[0042] The oil well cement is grade G oil well cement;

[0043] The fluid loss reducing agent is cellulose derivatives, specifically but not limited to carboxymethyl cellulose, hydroxyethyl cellulose or carboxymethyl hydroxyethyl cellulose;

[0044] The main component of the defoamer is tributyl phosphate;

[0045] A preparation method of urea-modified carbon nanotube cement slurry is the same as that in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com