Conjugated organic lithium ion battery electrode material and preparation method and application thereof

An electrode material, ion battery technology, applied in battery electrodes, organic chemistry, secondary batteries, etc., can solve problems such as reducing the energy density of organic electrodes, and achieve the effects of novel structure, low requirements for synthesis equipment, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

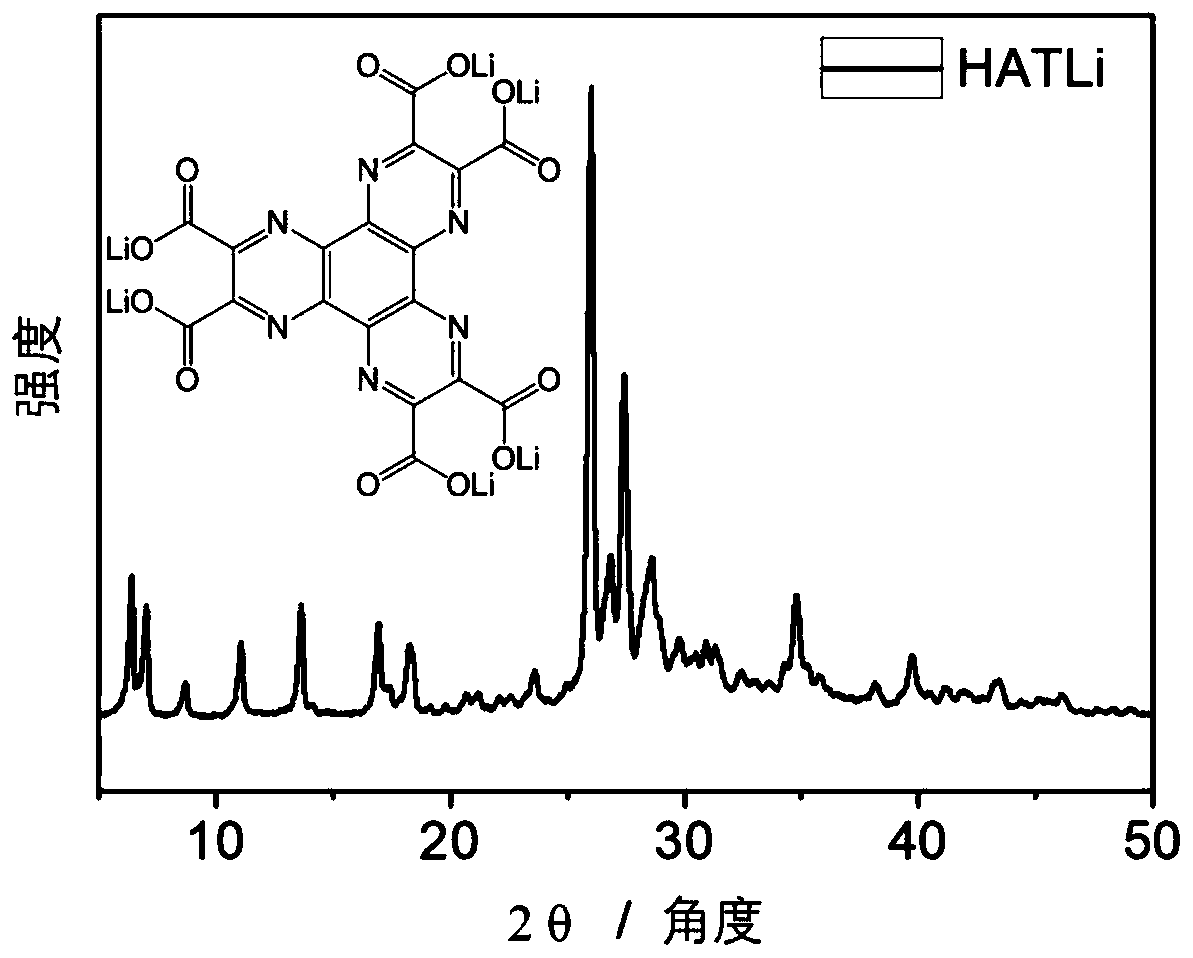

[0044] The preparation method of the above-mentioned conjugated organic lithium-ion battery electrode material comprises the following steps:

[0045] 1) Using compound 1 as a raw material, hydrolyze in the presence of concentrated sulfuric acid, the hydrolysis temperature is room temperature, and the hydrolysis time is 72h, to synthesize compound 2;

[0046]

[0047] 2) Compound 2 reacted with TFA, NaNO in the presence of AcOH 2 React at room temperature for 72h, wherein the mass ratio of TFA to compound 2 is 50:1, compound 2 and NaNO 2 The molar ratio is 1:9, then add EtOH solvent, continue with NaHCO 3 react with NaOH at room temperature for 12h, and finally add 6N HCl at 90°C for 1h to obtain H 6 -HAT;

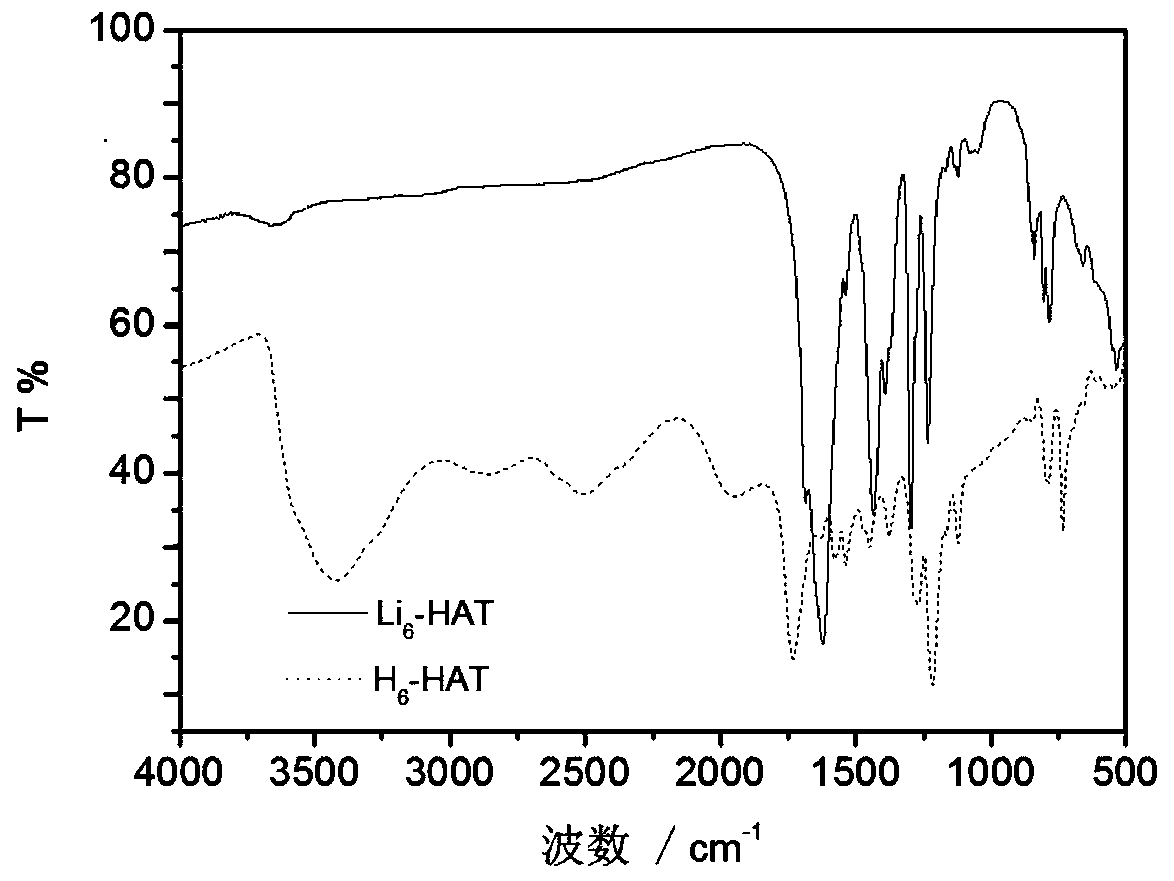

[0048] 3) will get H 6 -HAT was dissolved in an ethanol solution, an excess of lithium hydroxide solution was added, and the reaction was carried out at room temperature for 48 hours to obtain Li 6 -HAT compounds.

Embodiment 1

[0050] Conjugated organic lithium-ion battery electrode materials Li 6 The synthetic route of -HAT is as follows:

[0051]

[0052] Proceed as follows:

[0053] 1) Add 400 g of concentrated sulfuric acid to 10 g of compound 1, stir and react at room temperature for 72 h, filter after the reaction, wash the filtered solid with deionized water for 3 times, then wash with acetone for 3 times, and then vacuum-dry at 100 degrees for 14 h, Obtain compound 2, and the product yield can be realized above 87%;

[0054] 2) Add 4.92g of compound 2 to 150mL of trifluoroacetic acid (TFA) and stir at room temperature, then add 7.0g of sodium nitrite NaNO 2 React at room temperature, the mass ratio of TFA to compound 2 is 50:1, compound 2 and NaNO 2 The molar ratio is 1:9. A brown suspension was obtained after the reaction was complete. Add 150 mL of acetic acid, stir for 12 h, pour into 300 mL of ice water, and filter to obtain a solid product. Dissolve the solid product into 150 mL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com