Nano flower-shaped NiCoP supercapacitor electrode material, preparation method and application thereof

A technology of supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of poor conductivity and structural instability of metal-organic frameworks, and achieve improved conductivity and structural stability. Conductivity, the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A kind of preparation method of nano flower shape NiCoP supercapacitor electrode material, comprises the following steps:

[0032] S1. The preparation of the metal-organic framework material comprises the following steps:

[0033] 290mg Ni(NO 3 ) 2 ·6H 2 O, 125mg Co(NO 3 ) 2 ·6H 2 O, 50 mg H 4DOBDC and 1.5g of PVP were uniformly dispersed in 30ml of ethanol, distilled water and DMF with a volume ratio of 1:1:1 and stirred evenly; ℃ for hydrothermal reaction, the reaction time is 12 hours, after the reaction is completed, a turbid solution is obtained; the precipitation is collected by centrifugation at 7000r / min for 3 minutes, and the precipitation is washed with ethanol and distilled water in turn to remove the residual reagents and by-products; finally, at 70 Vacuum drying at ℃ to obtain the Ni / Co-MOFs precursor;

[0034] S2, the synthesis of three-dimensional nano flower-like double metal phosphide NiCoP, comprising the following steps:

[0035] Under an ult...

Embodiment 1

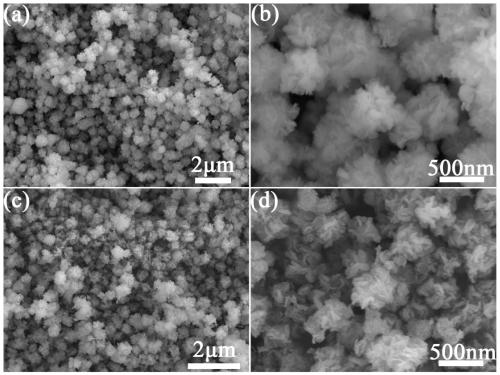

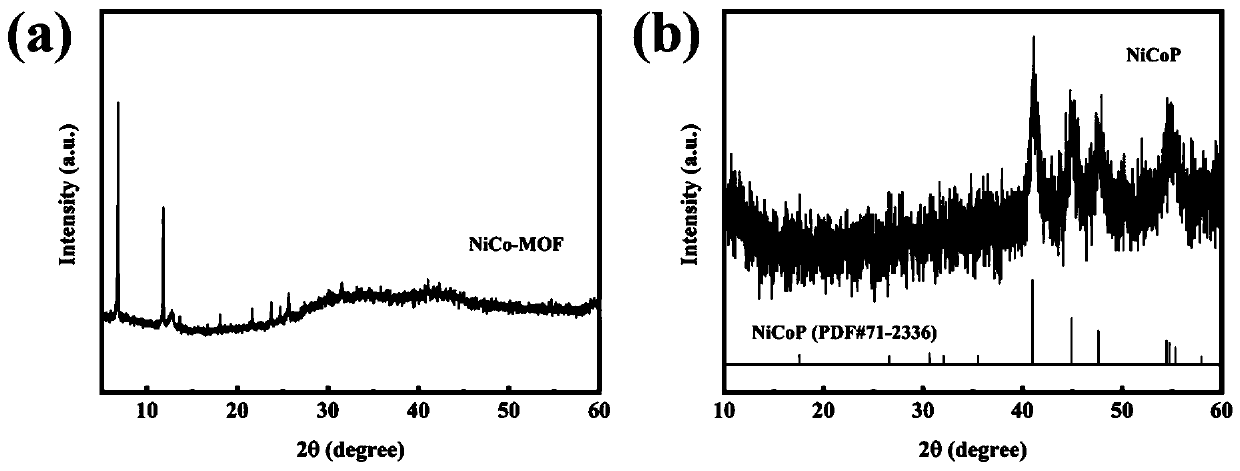

[0039] 290mg Ni(NO 3 ) 2 ·6H 2 O, 125mg Co(NO 3 ) 2 ·6H 2 O, 50 mg H 4 DOBDC and 1.5g PVP were uniformly dispersed in 30ml mixed solution (volume ratio of ethanol:distilled water:DMF was 1:1:1) and stirred evenly. The clarified solution was transferred to an autoclave, and then placed in a blast drying oven for hydrothermal reaction at a reaction temperature of 160° C. for 12 hours. After the reaction was completed, the precipitate was collected from the turbid solution by centrifugation (7000r / min, 3min), and the precipitate was washed with ethanol and distilled water in order to wash away residual reagents and by-products. Finally, the Ni / Co-MOFs precursor, that is, the Ni / Co metal-organic framework material, was obtained by vacuum drying at 70 °C.

Embodiment 2

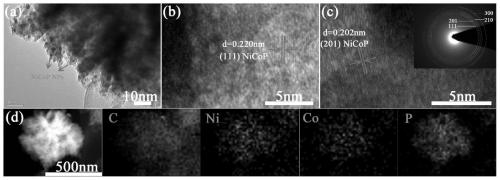

[0042] NiCoP composites were prepared by low-temperature phosphating of Ni / Co-MOFs in a tube furnace under an ultrapure Ar atmosphere. Ni / Co-MOFs (20mg) precursor and NaH 2 PO 2 2H 2 O points (120mg) were placed in two porcelain boats with NaH 2 PO 2 2H 2 The porcelain boat of O is located upstream of the ultrapure Ar gas flow, and the porcelain boat with Ni / Co-MOFs precursor is located at the upstream of the NaH 2 PO 2 2H 2 Downstream of the porcelain boat of O; then, the Ni / Co-MOFs precursor was heated to 300 °C for 2 h at a rate of 3 °C / min. After cooling to room temperature, a black and black three-dimensional nanoflower-like bimetallic phosphide NiCoP is obtained, which is denoted as NiCoP.

[0043] The nickel mesh is used as the current collector, and the nickel mesh does not provide electrochemical performance. According to the mass ratio, NiCoP: polyvinylidene fluoride: acetylene black = 8:1:1 (where: the amount of NiCoP is 30mg) mixed and transferred to 30ml ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com