Composite concrete containing mixed fibers and manufacturing method thereof

A technology of mixing fiber and concrete, which is applied in the field of building materials for construction, can solve the problems of affecting concrete strength and flexural impact performance, the reduction of various concrete properties, and the obvious crack resistance of concrete, etc., to achieve good flexural bearing capacity and plastic shrinkage The effect of excellent ability and comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

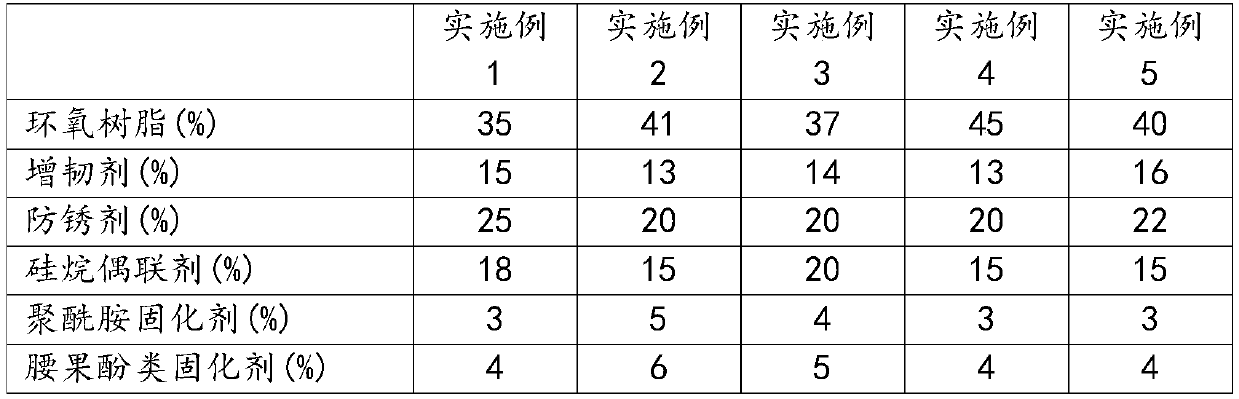

[0034] Embodiment: a kind of composite concrete containing mixed fiber, described concrete comprises cement composition and the mixed fiber filled in described cement composition, and described mixed fiber comprises steel fiber, carbon fiber and polypropylene fiber, and described steel fiber The shape is at least two of elongated, dendritic, columnar, polygonal and polyhedron, the volume of the steel fibers accounts for 0.4%-1.5% of the total volume of the concrete, and the volume of the carbon fibers accounts for 0.4%-1.5% of the total volume of the concrete. 0.2%-0.4% of the total volume, the polypropylene fiber accounts for 0.1%-0.3% of the total volume of the concrete;

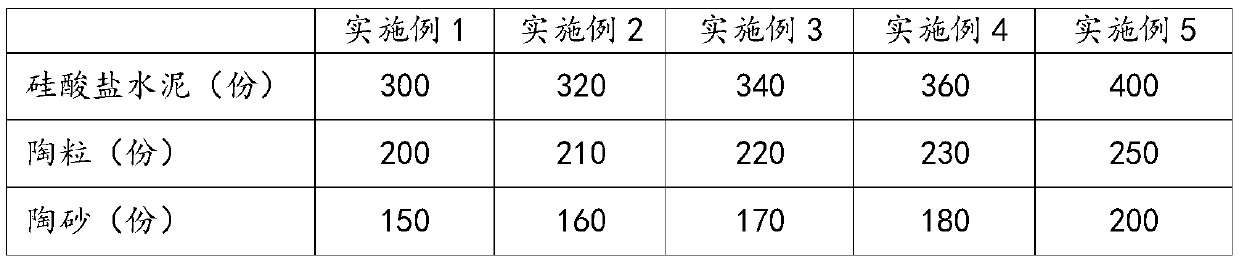

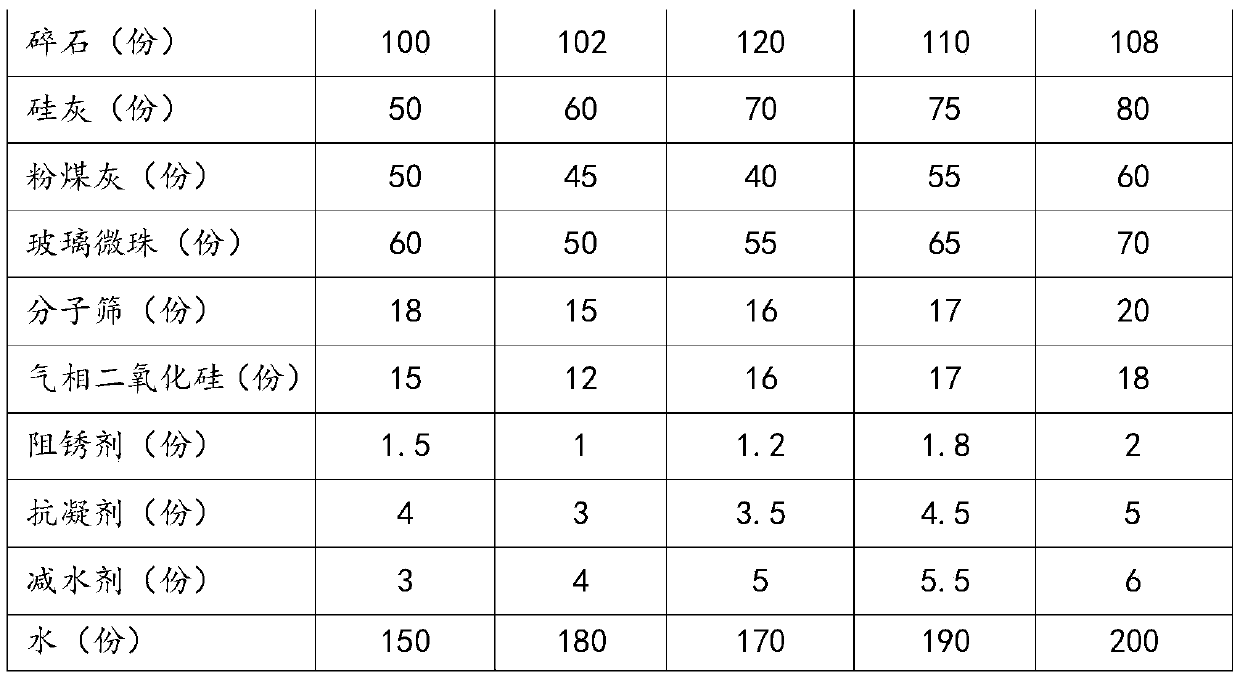

[0035] The cement composition includes the following raw materials in parts by weight: 300-400 parts of Portland cement, 200-250 parts of ceramsite, 150-200 parts of pottery sand, 100-120 parts of gravel, and 50 parts of silica fume. -80 parts, 40-60 parts of fly ash, 50-70 parts of glass beads, 15-20 part...

Embodiment 3

[0056] In Example 3 and Example 4, the volume of the steel fiber accounts for 1.0% of the total volume of the concrete, the volume of the carbon fiber accounts for 0.3% of the total volume of the concrete, and the polypropylene fiber accounts for 0.3% of the total volume of the concrete. 0.2% of the volume; the volume ratio of elongated steel fibers, dendritic steel fibers, cylindrical steel fibers and polygonal steel fibers is 1:3:3:2.5;

Embodiment 5

[0057] In Example 5, the volume of the steel fiber accounts for 1.5% of the total volume of the concrete, the volume of the carbon fiber accounts for 0.2% of the total volume of the concrete, and the polypropylene fiber accounts for 0.1% of the total volume of the concrete ; Wherein the volume ratio of elongated steel fibers, dendritic steel fibers, columnar steel fibers and polygonal steel fibers is 1:2.5:3.5:2.2.

[0058] The preparation method of a kind of composite concrete containing mixed fibers described in embodiment 1 to embodiment 5 is carried out according to the following steps:

[0059] Step 1. Put the steel fiber in the raw material solution for forming the epoxy resin antirust layer, and stir for 5-10 minutes, so that the surface of the steel fiber is evenly coated with the raw material solution, and then under the condition of 90-140°C Dry for 10-15min;

[0060] Step 2. Mix ceramsite, ceramic sand, glass microspheres, molecular sieve, fumed silica and half of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com