Clean process for continuously synthesizing glycine

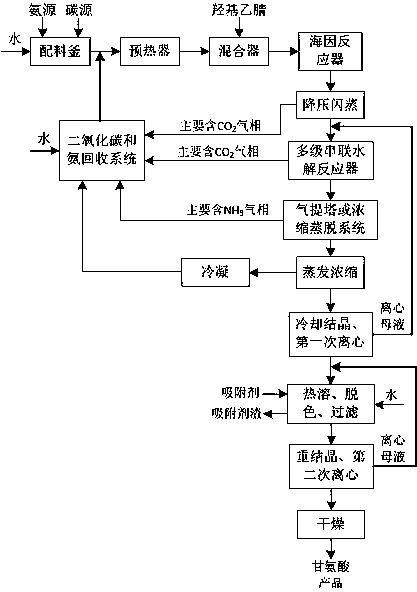

A process method and technology of glycine, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as low hydrolysis single-pass yield, long hydrolysis time, and difficulty in applying mechanically, so as to shorten the hydrolysis reaction time, Facilitate absorption and improve single-pass conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

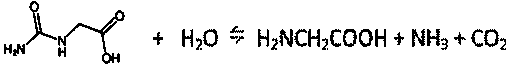

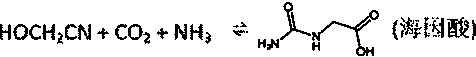

Method used

Image

Examples

Embodiment 1

[0047] Example 1: Ammonia, carbon dioxide and water are prepared in a molar ratio of 1:1:12 to prepare an aqueous solution of carbon dioxide and ammonia. The feed flow rate is 390kg / h, which is preheated to 80°C by a preheater, and 44wt% of the feed flow rate is 63.5kg / h The concentrated hydroxyacetonitrile solution is mixed rapidly in a static mixer, enters the column reactor from the bottom, and reacts at a pressure of 5.5 MPa and a temperature of 110°C for 45 minutes to obtain a hydantoin synthetic liquid, which then flows out from the top of the reactor and enters a decompression flasher; The operating pressure of the evaporator is 1.5MPa, and the gas phase separated by flash is removed from the carbon dioxide and ammonia recovery system, and the liquid phase enters 3-stage series column reactors for continuous hydrolysis, and the materials of each stage of the reactor enter from the bottom and flow out from the top; the hydrolysis reaction The operating pressure of the rea...

Embodiment 2

[0050] Example 2: Ammonia, carbon dioxide and water are prepared in a molar ratio of 1:1.15:15 to prepare an aqueous solution of carbon dioxide and ammonia. The feed flow rate is 4200kg / h, preheated to 80°C by a preheater, and the feed flow rate is 590kg / h with a concentration of 40wt%. The hydroxyacetonitrile solution is mixed rapidly in a static mixer, enters the tube bundle reactor from the bottom, reacts at a pressure of 4.5MPa and a temperature of 120°C for 35min, and then flows out from the top of the reactor into a decompression flasher; the operating pressure of the flasher is 1.0MPa, The gas phase of flash separation is used to remove carbon dioxide and ammonia recovery system, and the liquid phase enters the compound reactor combining 5-stage series column reactors and tube bundle reactors for continuous hydrolysis. The materials of each stage of reactor enter from the bottom, from The upper part flows out; the operating pressure of the hydrolysis reactor is 2.5MPa, a...

Embodiment 3

[0053] Example 3: Ammonia, carbon dioxide and water are prepared in a molar ratio of 1:1.2:15 to prepare an aqueous solution of carbon dioxide and ammonia. The feed flow rate is 4250kg / h, preheated to 90°C by a preheater, and the feed flow rate is 670kg / h with a concentration of 38wt%. The hydroxyacetonitrile solution is mixed rapidly in a static mixer, enters a column reactor from the bottom, reacts at a pressure of 4.0MPa and a temperature of 100°C for 60min, and then flows out from the top of the reactor into a decompression flasher; the operating pressure of the flasher is 2.2MPa, The flash separation gas phase removes carbon dioxide and ammonia recovery system, and the liquid phase enters a compound reactor combining 6-stage series column reactors and tube-bundle reactors for continuous hydrolysis. The materials of each stage of reactor enter from the bottom, from Outflow from the upper part; the operating pressure of the hydrolysis reactor is 3.8MPa, and the temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com