Bus disinfection system

A bus and disinfectant technology, applied in disinfection, mixers, water/sludge/sewage treatment, etc., can solve the problems of human health damage, hidden safety hazards, high cost, etc., and achieve wide spraying area, high disinfection efficiency, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

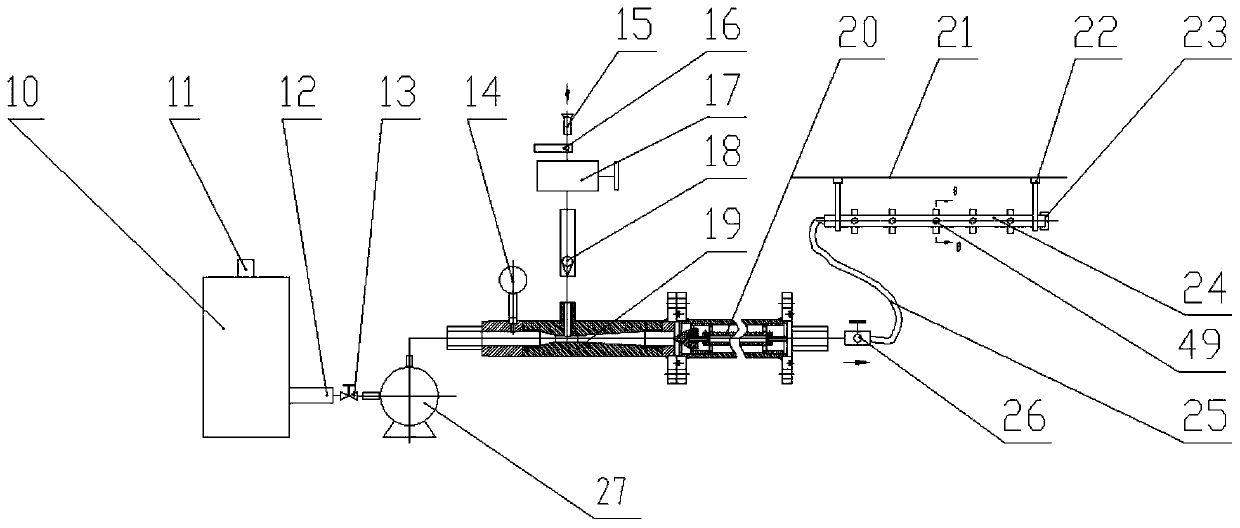

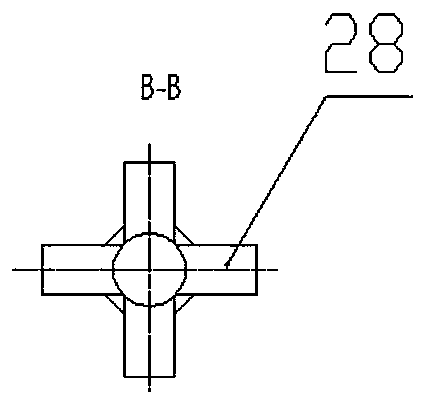

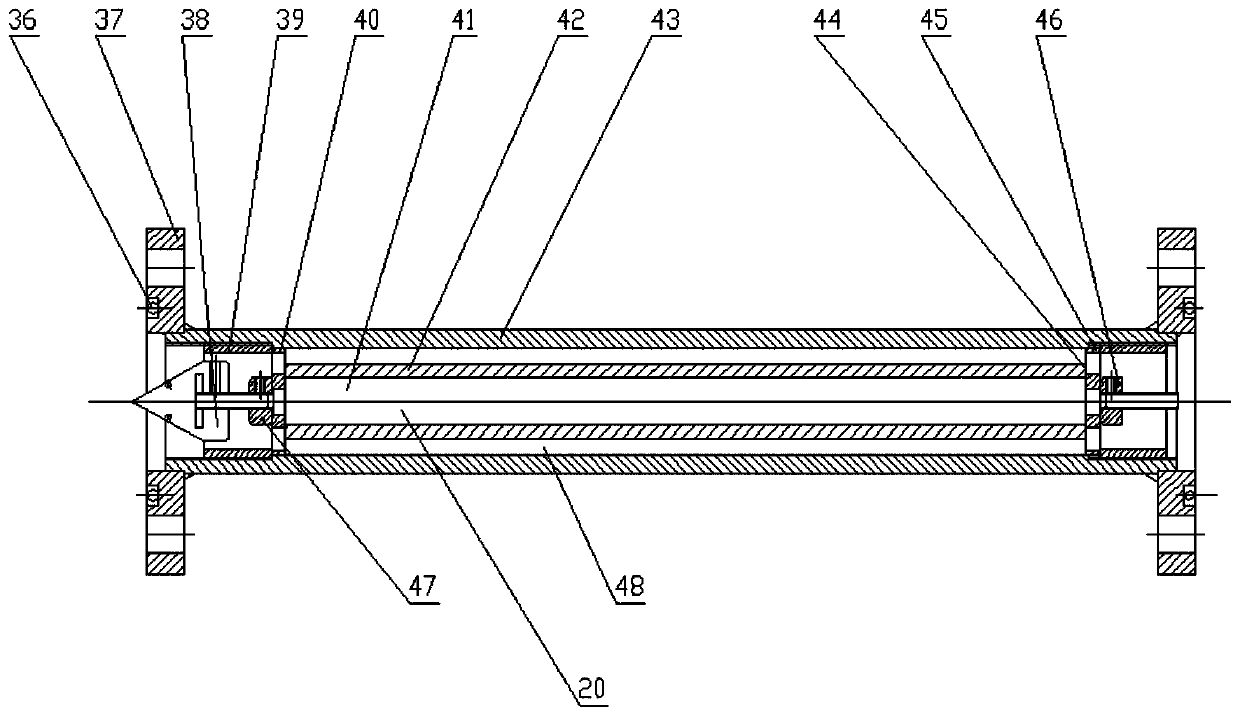

[0072] A bus disinfection system and its environment-friendly disinfection water are composed of a people flow counting system, a disinfectant solution preparation system and a disinfectant solution spraying system. The gas source is air, and the inner diameter of the cutting tube is φ24mm. The water source is tap water, the air flow rate is 3L / min, the water inlet pressure is 0.3Mpa, and the water flow rate is 1m 3 / h, the cutting linear velocity of water flow is 1.3m / s, the linear velocity of water flowing through the helical cutting channel 48 of micro-nano bubble generator 20 is 1.3m / s, the particle size of the generated nano-bubbles is 100-200nm, and the number of bubbles is 1-200nm. 10e 8 per ml, the dissolved oxygen is 15~18mg / L. Among them, active hydroxyl radicals (hydroxyl) and peroxyl and other active oxygen components exceed 20% (wt), which can kill all bacteria and viruses within 10 seconds, do not hurt the skin, and are environmentally friendly and energy-savin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com