Catalyst and preparation method thereof

A technology of catalyst and complexing agent, applied in catalyst preparation and catalyst field, can solve the problems of low service life, uniform distribution of difficult-to-active components, high production cost, etc. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the catalyst according to the concept of the present invention includes the preparation step of the functionalized polymer / carrier precursor, the preparation step of the transition metal-rare earth-polymer complex / carrier precursor and the preparation step of the catalyst. Hereinafter, each step according to the inventive concept will be described in detail.

[0031] Preparation steps of functionalized polymer / carrier precursor

[0032] The preparation step of the functionalized macromolecule / carrier precursor may include: providing a carrier on which the organic macromolecule is loaded, and utilizing a complexing agent to functionalize the organic macromolecule on the carrier, thereby obtaining the functionalized macromolecule / carrier precursor ( Hereinafter, referred to as "first precursor").

[0033] Specifically, the step of preparing the first precursor according to an exemplary embodiment of the present invention may include a step of p...

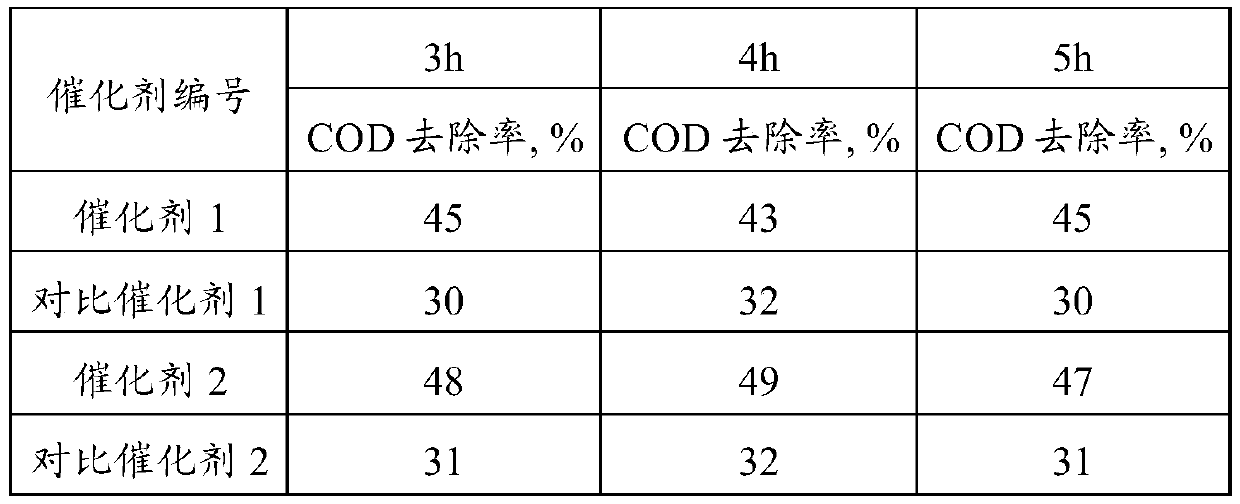

Embodiment 1

[0060] A. Functionalization-PVC / Al 2 o 3 Precursor preparation:

[0061] Weigh a diameter of 4.5mm, a length of 4.5mm, and a specific surface area of 150m 2 / g, columnar α-Al with a pore volume of 0.3mL / g 2 o 3 Carrier 100 g. 12g of PVC (polyvinyl chloride) was completely dissolved in 1000mL of THF (tetrahydrofuran) to obtain an organic polymer solution, and then, 100g of columnar α-Al 2 o 3 Immerse the carrier into the organic polymer solution and let it stand for 1h to make PVC adsorb on the columnar α-Al 2 o 3 s surface. followed by drying to obtain PVC / Al 2 o 3 Precursor.

[0062] Then, 16.12 g of dicyandiamide was added to 1500 mL of deionized water to obtain an aqueous solution of dicyandiamide, after which PVC / Al was added to the aqueous solution of dicyandiamide 2 o 3 The precursor was refluxed for 4h, then cooled to 25°C and filtered, the filtrate was washed with deionized water until neutral, and dried for later use to obtain functionalized-PVC / Al 2 o...

Embodiment 2

[0070] A. Functionalization-SAN / Al 2 o 3 Precursor preparation:

[0071] Weigh the diameter of 3mm-5mm, specific surface area of 180m 2 / g, spherical γ-Al with a pore volume of 0.35mL / g 2 o 3 Carrier 100 g. 29.16g of SAN (the molar ratio of styrene monomer to acrylonitrile monomer is 1:1) was completely dissolved in 1500mL of DMF (dimethylformamide) to obtain an organic polymer solution, and then, 100g of spherical γ-Al 2 o 3 Immerse the carrier into the organic polymer solution and let it stand for 6 hours to make SAN adsorb on the spherical γ-Al 2 o 3 surface of the carrier, followed by drying to obtain SAN / Al 2 o 3 Precursor.

[0072] Then, 11.14 g of ethylenediamine was added to 1000 mL of deionized water to obtain an aqueous solution of ethylenediamine, after which SAN / Al was added to the aqueous solution of ethylenediamine 2 o 3 The precursor was refluxed for 1 h, then cooled to 25 °C and filtered, washed with deionized water until neutral, and dried for l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com