Olefin cracking catalyst, preparation method thereof and olefin cracking method

A technology for cracking catalysts and olefins, which is applied in the fields of hydrocarbon cracking to produce hydrocarbons, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of high process cost, unfavorable catalyst regeneration, low ethylene selectivity, etc., and achieves high yield and cracking process. cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

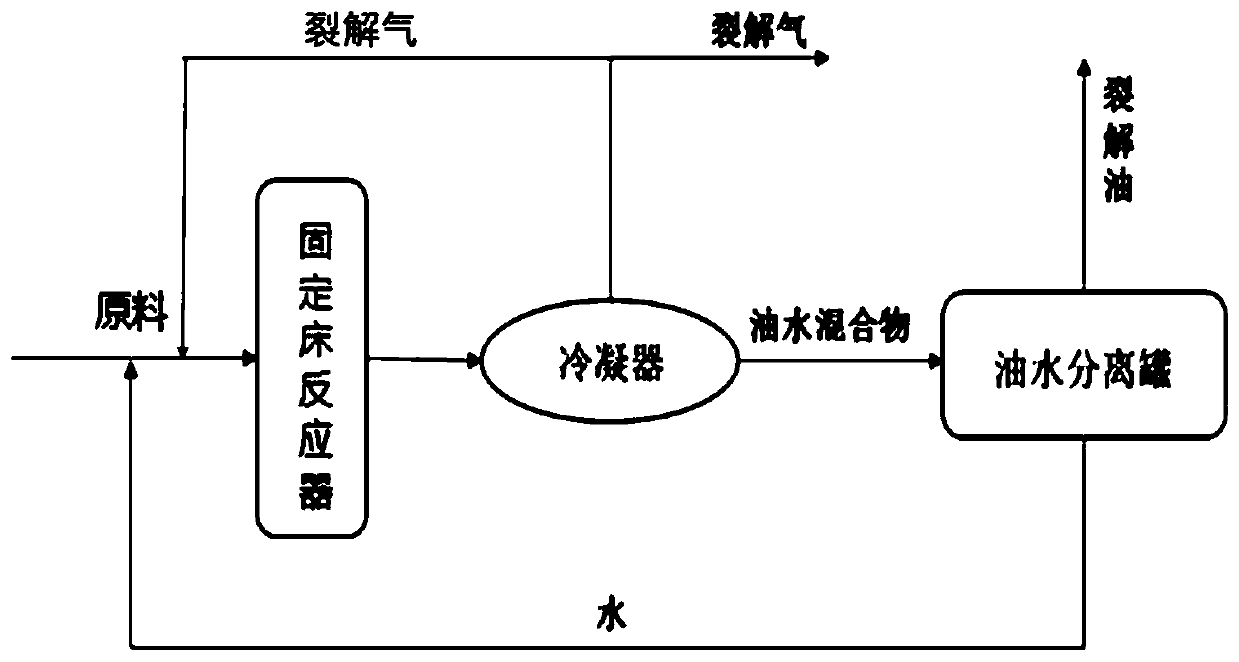

Method used

Image

Examples

Embodiment 1

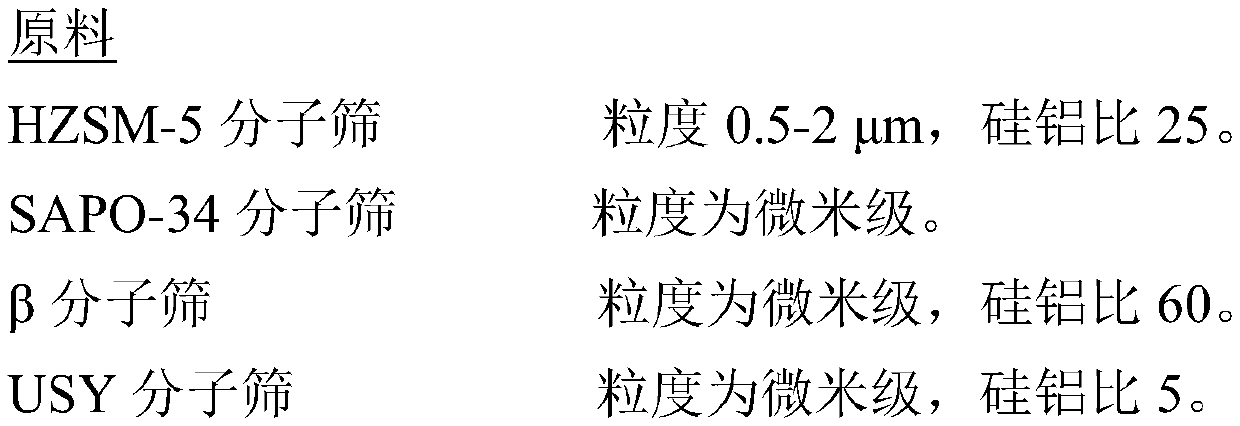

[0058] (1) HZSM-5 molecular sieve treated by cation exchange and SAPO-34 molecular sieve treated by acid

[0059] The HZSM-5 molecular sieve was added to 0.1 mol / L NaOH solution, so that the mass ratio of HZSM-5 molecular sieve:NaOH solution was 1:6, and the mixed slurry of cation exchange treatment was obtained. The cation exchange treatment mixture was heated to about 90° C. in a water bath, maintained at this temperature for about 2 hours, and the HZSM-5 molecular sieve filter cake was filtered off with suction and washed until neutral. The obtained molecular sieve filter cake was dried in an oven at 120° C. for 4 hours, and then placed in a muffle furnace for calcination at 540° C. for 4 hours to obtain a cation exchange-treated HZSM-5 molecular sieve.

[0060] Add SAPO-34 molecular sieve to 0.06mol / L HNO 3 In solution, SAPO-34 molecular sieve: HNO 3 The mass ratio of the solution is 1:6 to obtain an acid-treated mixture. The acid treatment mixture was heated to about 9...

Embodiment 2

[0080] The catalyst was prepared according to the same procedure as in Example 1, except that the types of molecular sieves were different:

[0081] The SAPO-34 molecular sieve was replaced with β molecular sieve, and the method for cation exchange treatment of β molecular sieve and HZSM-5 molecular sieve was the same as that in Example 1, and the HZSM-5 and β molecular sieve after cation exchange treatment were mixed with a mass ratio of 3:1 to obtain HZSM -5 / β composite molecular sieve.

[0082] Other operations were the same as in Example 1, and catalyst B was prepared.

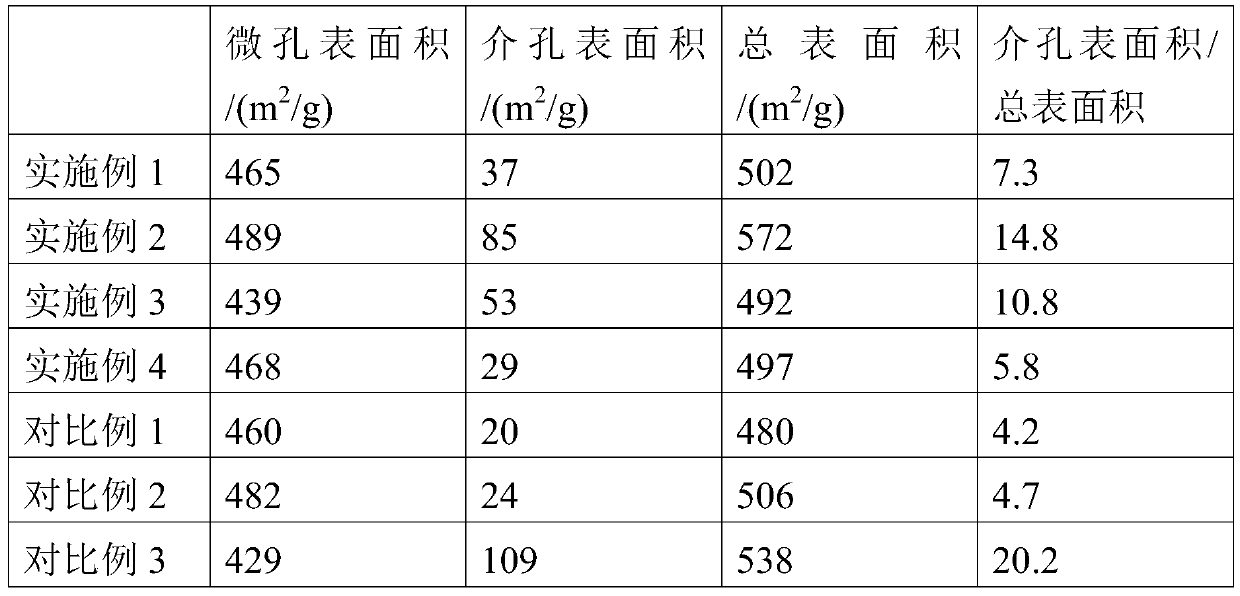

[0083] The catalytic effect evaluation experiment of catalyst B is the same as the catalytic cracking of catalytic cracking C4-C5 gasoline fraction in Example 1, and the results are shown in Table 1.

Embodiment 3

[0085] The catalyst was prepared according to the same procedure as in Example 1, except that the types of molecular sieves were different:

[0086] The molecular sieve is added with USY molecular sieve, and the cation exchange treatment process is the same as the cation exchange treatment process of HZSM-5 molecular sieve in Example 1. Proportions are mixed to obtain HZSM-5 / USY / SAPO-34 composite molecular sieve, other operations are the same as in Example 1, and catalyst C is prepared.

[0087] Taking catalytic cracking C4-C5 gasoline fractions as raw materials, the catalytic effect evaluation experiment of catalyst C is the same as that in Example 1, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com