Catalyst for synthesizing diethyl oxalate by carbon monoxide gas-phase coupling of ethyl nitrite and preparation method and application thereof

A technology of ethyl nitrite and diethyl oxalate, applied in the direction of carbon monoxide or formate reaction preparation, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, etc., can solve the most difficult problems without industrialization. Excellent conditions, serious thermal migration, and high load, to achieve the effect of clever design, high dispersion, and improved dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1-3

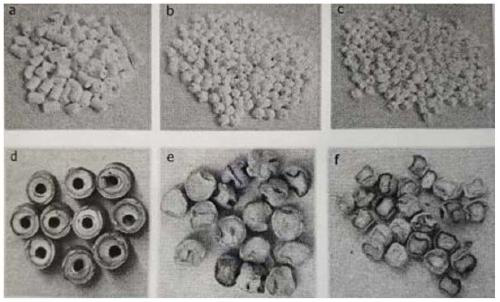

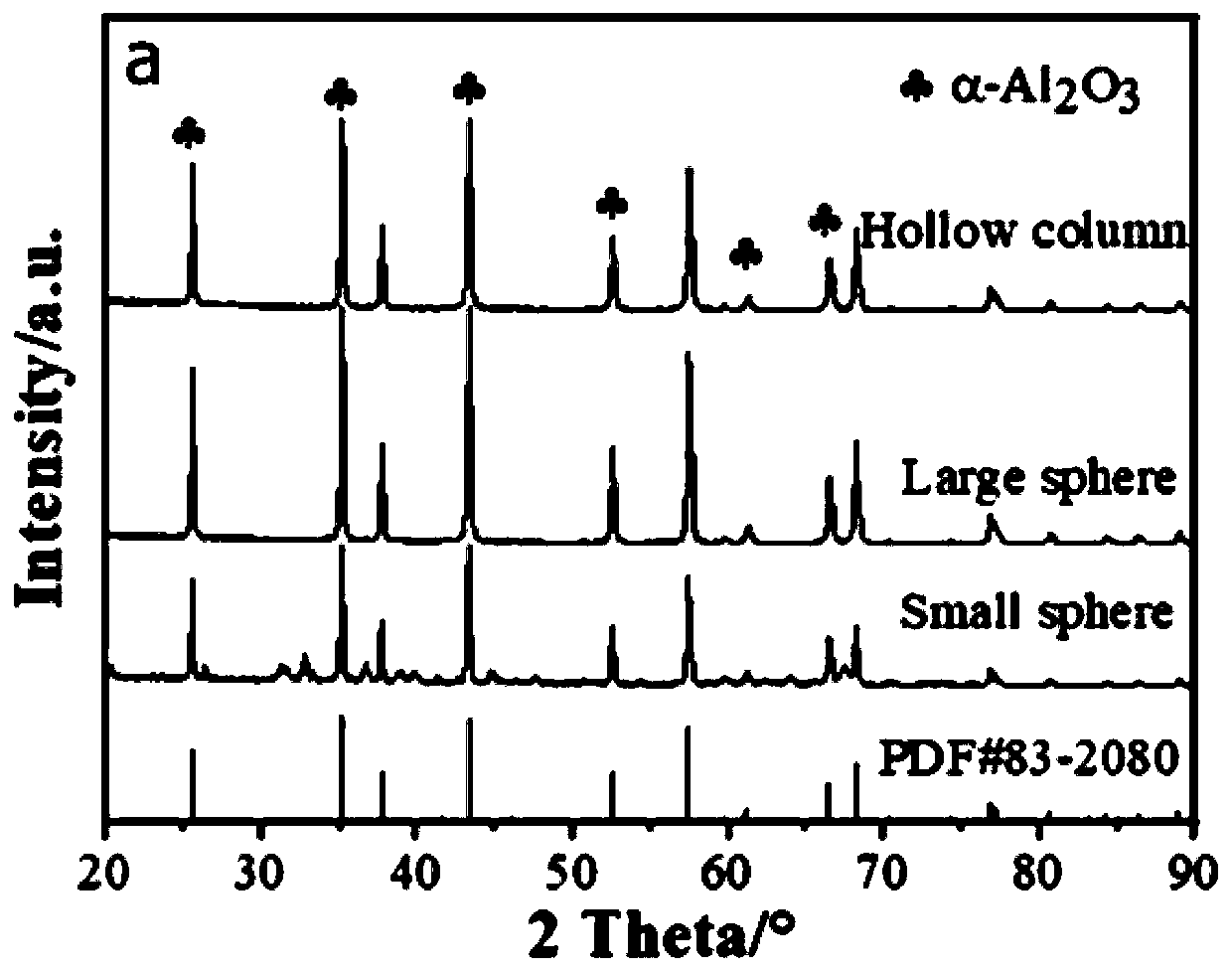

[0055] In order to compare with the preparation method of the catalyst described in the present invention, the traditional method previously reported was first selected to prepare the catalyst for the synthesis of diethyl oxalate by gas-phase coupling of carbon monoxide with ethyl nitrite, and the effects of different morphology supports were investigated, and the specific preparation Proceed as follows:

[0056] S1 carrier γ-Al 2 o 3 Pretreatment: 100g of commercially available large balls with an average diameter of 3.32mm and small balls with an average diameter of 2.36mm; commercial Raschig rings with an average size of outer diameter 3.8mm, inner diameter 1.0mm, and height 5.8mm Carrier γ-Al 2 o 3 Place it on a high-temperature muffle furnace and set the heating program to bake at 1200°C for 4 hours, and set aside;

[0057] Preparation of mixed solution of S2 palladium salt and iron salt: dissolve soluble palladium salt and iron salt in deionized water, place the solu...

Embodiment example 4-8

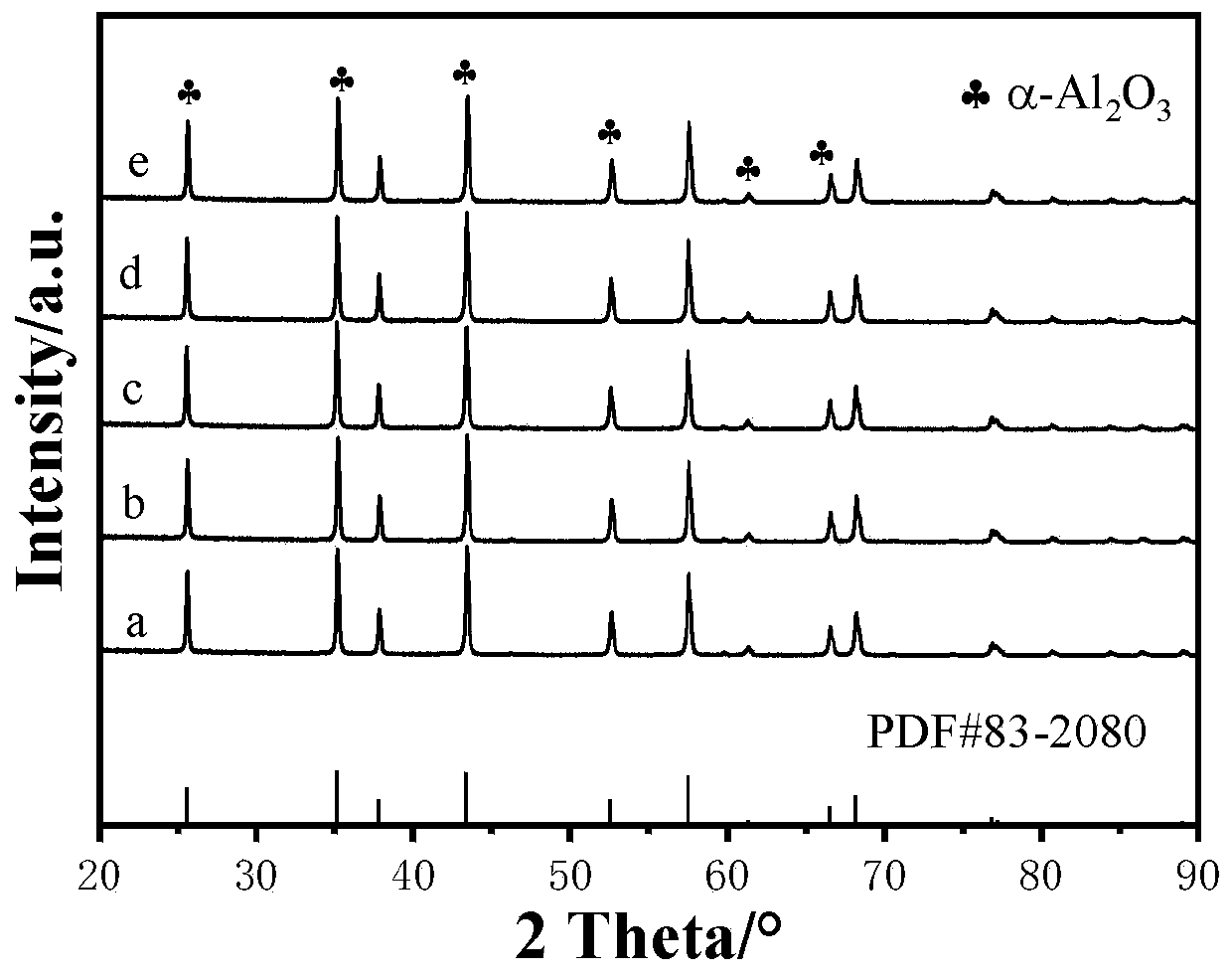

[0064] Carry out the preparation of carbon monoxide gas-phase coupling ethyl nitrite synthesis diethyl oxalate catalyst according to the preparation method of catalyst of the present invention, concrete preparation steps are as follows:

[0065] S1 carrier γ-Al 2 o 3 Pretreatment: 100g of the commercial Raschig cyclic carrier γ-Al 2 o 3 , the average size is: γ-Al with an outer diameter of 3.8mm, an inner diameter of 1.0mm, and a height of 5.8mm 2 o 3 Put it on a high-temperature muffle furnace and set the temperature rise program at 1200 ° C for 4 hours to obtain α-Al 2 o 3 carrier, spare;

[0066] Preparation of mixed solution of S2 palladium salt and iron salt: Dissolve soluble palladium salt and iron salt in deionized water, add different substances or co-stabilizers of different concentrations, and drop concentrated hydrochloric acid immediately during the stirring process, with a mass fraction of 37.5 %. Adjust the pH of the solution to 1, place the solution in a...

Embodiment example 9-10

[0072] In order to compare with the preparation method of the catalyst described in the present invention, prove that the catalytic activity of the present invention is high, select the traditional method of previous report again, carry out carbon monoxide vapor phase coupling ethyl nitrite synthetic diethyl oxalate by increasing the palladium loading capacity of double The preparation of ester catalyst, namely the palladium load of preparing catalyst respectively is 0.1wt% (invention method) and 1wt% (traditional method) as contrast, and concrete preparation steps are as follows:

[0073] S1 carrier γ-Al 2 o 3 Pretreatment: 100g of commercial Raschig cyclic carrier γ-Al 2 o 3 Place it on a high-temperature muffle furnace and set the heating program to bake at 1200°C for 4 hours, and set aside;

[0074] Preparation of S2 palladium salt and iron salt mixed solution: dissolve soluble palladium salt and iron salt in deionized water, and drop concentrated hydrochloric acid imme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com