Green and environment-friendly conductive nano-copper ink and preparation method thereof

A green, environmentally friendly, conductive ink technology, applied in nanotechnology, ink, metal processing equipment, etc., to achieve the effects of high repeatability, good process stability, mild and pollution-free reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Weigh 3g of copper hydroxide and add it to 150ml of ethanol solvent and mix evenly, heat to 50°C after continuous stirring, and obtain solution a after completely dissolving; weigh 15g of ascorbic acid as a reducing agent, then weigh 2g of polyvinylpyrrolidone ( K-20) as a protective agent, mix the two evenly, add to 150ml ethanol to dissolve, continue stirring and heat to 50°C, and obtain solution b after complete dissolution.

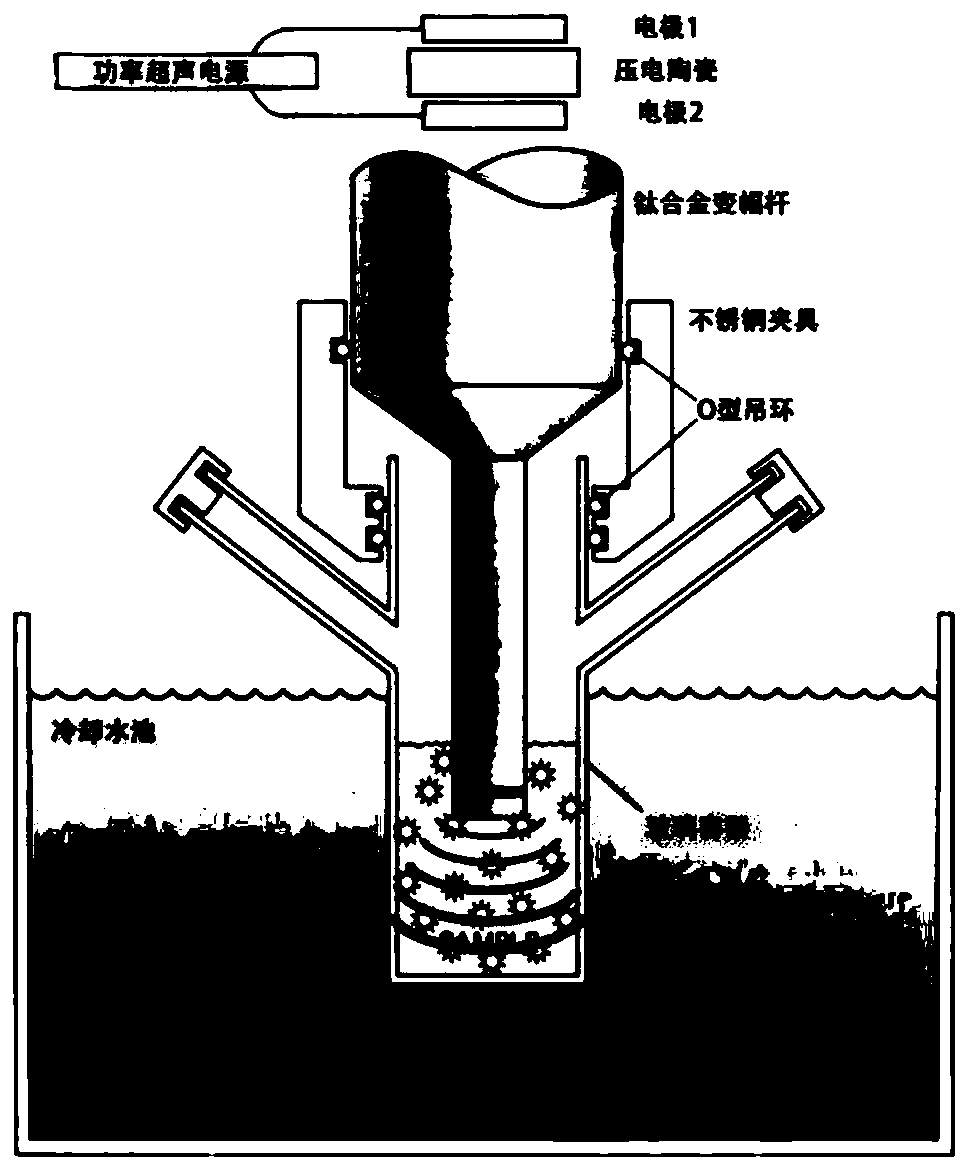

[0049] (2) Place solution b in a pulsed ultrasonic device that applies a direct downward action. The preset ultrasonic parameters: power 1000W, frequency 20KHz, pulse ratio 3:1, after heating to 50°C, pour solution a quickly React in solution b for 10 min, and after the solution changes from light blue to dark red, a copper nanoparticle solution is obtained.

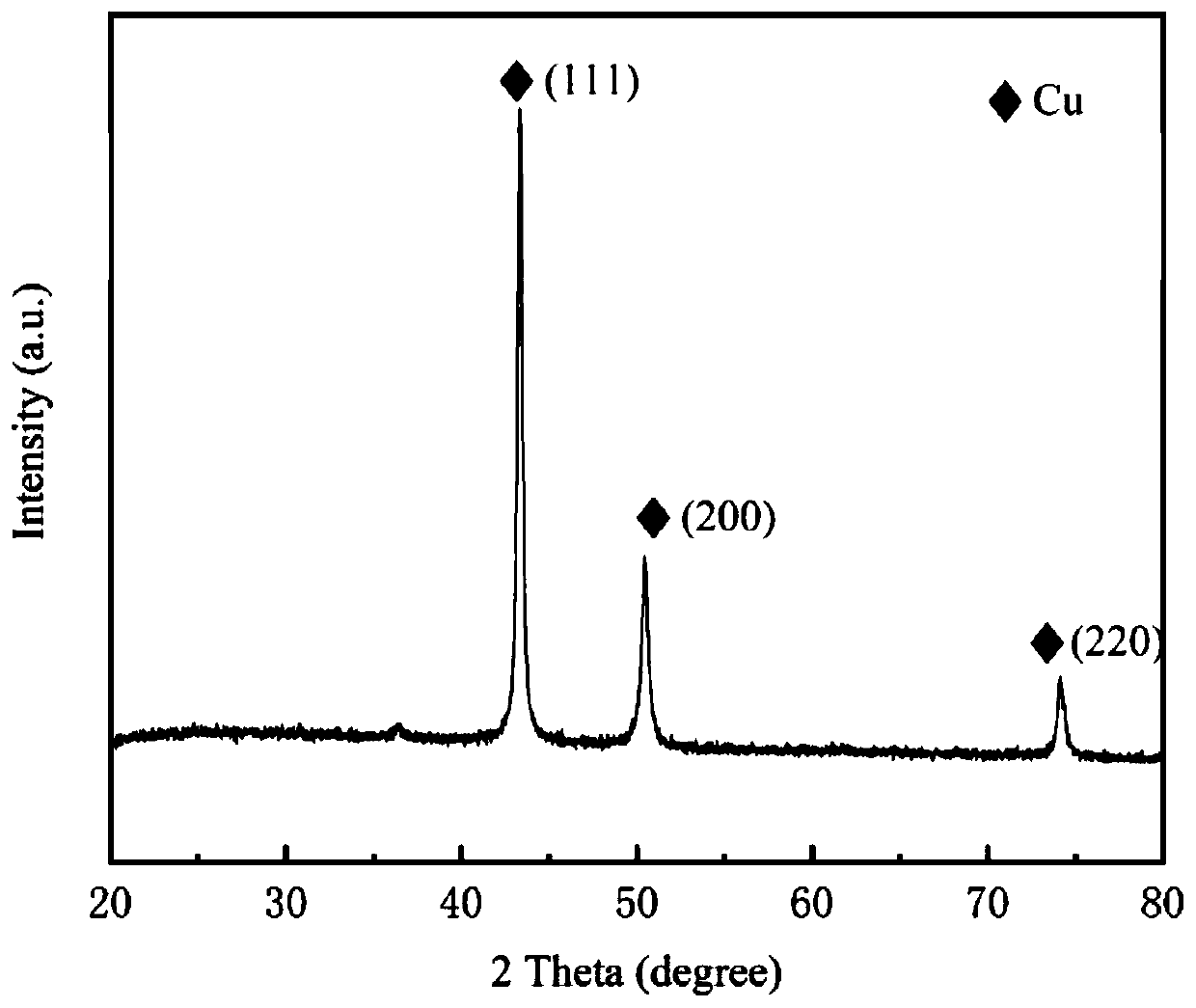

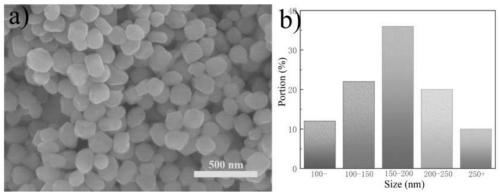

[0050] (3) Cool the copper nanoparticle solution obtained in step (2) to room temperature, and centrifuge and wash with 4000r / min deionized water for 4 times to obtain pure copper nan...

Embodiment 2

[0054] (1) Weigh 5g of copper acetate and add it to 100ml of ethanol solvent, mix evenly, heat to 100°C after continuous stirring, and obtain solution a after completely dissolving; weigh 10g of sodium borohydride as a reducing agent, and then weigh 2g of polyvinylpyrrolidone (K-20) as a protective agent, mix the two evenly, add to 100ml of ethanol to dissolve, continue to stir and heat to 100°C, and obtain solution b after complete dissolution.

[0055] (2) Place solution b in a pulsed ultrasonic device that acts directly downward. The pre-set ultrasonic parameters are: power 1200W, frequency 35KHz, pulse ratio 4:1. After heating to 100°C, quickly pour solution a React in solution b for 10 min, and after the solution changes from light blue to dark red, a copper nanoparticle solution is obtained.

[0056] (3) Cool the copper nanoparticle solution obtained in step (2) to room temperature, and centrifuge and wash with 4000r / min deionized water for 4 times to obtain pure copper ...

Embodiment 3

[0059] (1) Weigh 10g copper sulfate and add it to 100ml ethanol solvent and mix evenly, heat to 80°C after continuous stirring, and obtain solution a after completely dissolving; weigh 20g ascorbic acid as reducing agent, then weigh 5g polyvinylpyrrolidone (K -30) As a protective agent, the two are mixed evenly and then dissolved in 100ml of ethanol, heated to 80°C after continuous stirring, and solution b is obtained after complete dissolution.

[0060] (2) Place solution b in a pulsed ultrasonic device that acts directly downward. The pre-set ultrasonic parameters are: power 1500W, frequency 40KHz, pulse ratio 5:1. After heating to 80°C, pour solution a quickly React in solution b for 10 min, and after the solution changes from light blue to dark red, a copper nanoparticle solution is obtained.

[0061] (3) Cool the copper nanoparticle solution obtained in step (2) to room temperature, and centrifuge and wash with 4000r / min deionized water for 4 times to obtain pure copper n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com