High-strength waterproof ventilated composite dressing and preparation method thereof

A waterproof, breathable, high-strength technology, used in dressings, non-adhesive dressings, bandages, etc., which can solve the problems of affecting the ventilation effect and the difficulty of combining PTFE and hydrogel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

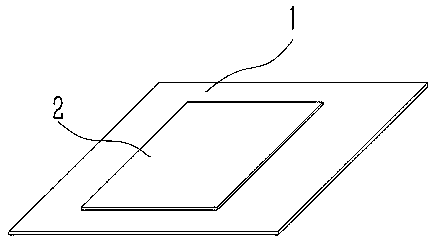

Image

Examples

Embodiment 1

[0045] Embodiment 1: the composite of expanded polytetrafluoroethylene and PVA hydrogel

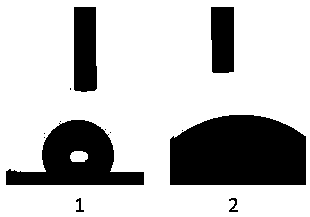

[0046] (1) Activation: Select an uncoated double-stretched expanded polytetrafluoroethylene film with a pore size of 0.1 microns and a thickness of 150 microns, cut the film into a square of 10cmx10cm; fix the expanded polytetrafluoroethylene film on a flat glass, put Into the 20MHz vacuum plasma generation chamber; evacuate and feed the argon gas at a flow rate of 20mL / min, adjust the equipment power to 115w, control the vacuum degree of the system to 0.095MPa, and conduct plasma treatment for 100s.

[0047] (2) Grafting: Immediately transfer the film to a special mold, add 1mol / L vinylpyrrolidone aqueous solution, and pass through nitrogen to remove oxygen, then transfer to a UV lamp for irradiation and grafting for 6 hours.

[0048] (3) Cleaning: Immerse the membrane in deionized water and change the water every 8 hours for a total of 24 hours.

[0049] (4) Composite: Transfer the cle...

Embodiment 2

[0052] Embodiment 2: Composite of expanded polytetrafluoroethylene and hydroxyethyl methacrylate hydrogel

[0053] In Example 2, the pretreatment method of the expanded polytetrafluoroethylene membrane is the same as that of Example 1, except that the preparation of the hydrogel, that is, the step (4) is different.

[0054] (4) Composite: The plasma-activated and PVP-grafted basement membrane was transferred to the hydrogel preparation fixture. Prepare a hydroxyethyl methacrylate solution with a concentration of 1mol / L, and add a crosslinking agent N,N-methylenebisacrylamide (concentration of 1 mol% of the monomer concentration) and an initiator α-pentyl Diacid (0.1 mol% of monomer concentration). Nitrogen was passed through the above solution to remove oxygen, and transferred to a mold with a base film, and irradiated under 365nm ultraviolet light for 12h. Take it out and soak it in deionized water for 24 h, and change the deionized water three times during this period to p...

Embodiment 3

[0056] Embodiment 3: Composite of expanded polytetrafluoroethylene and polymethacrylic acid hydrogel

[0057] In Example 3, the pretreatment method of the expanded polytetrafluoroethylene membrane is the same as that of Example 1, except that the preparation of the hydrogel, that is, step (4) is different.

[0058] (4) Composite: The plasma-activated and PVP-grafted basement membrane was transferred to the hydrogel preparation fixture. Prepare a methacrylic acid solution with a concentration of 1 mol / L, and add the initiator α-glutaric acid (0.1 mol% of the monomer concentration) into it. Nitrogen was passed through the above solution to remove oxygen, and transferred to a mold with a base film, and irradiated under 365 nm ultraviolet light for 12 hours. Take it out and soak it in deionized water for 24 h, and change the deionized water three times during this period to prepare a composite hydrogel.

[0059] (5) Post-processing: Coating polyacrylate pressure-sensitive adhesi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com