Sterilization method of cold-sprayed electric heating coating

A technology of cold spraying and coating, applied in the direction of heating, pressure inorganic powder coating, etc., can solve the problems of high oxidation rate, complicated preparation process, environmental pollution, etc., and achieve the effect of avoiding pollution and highly effective antibacterial

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

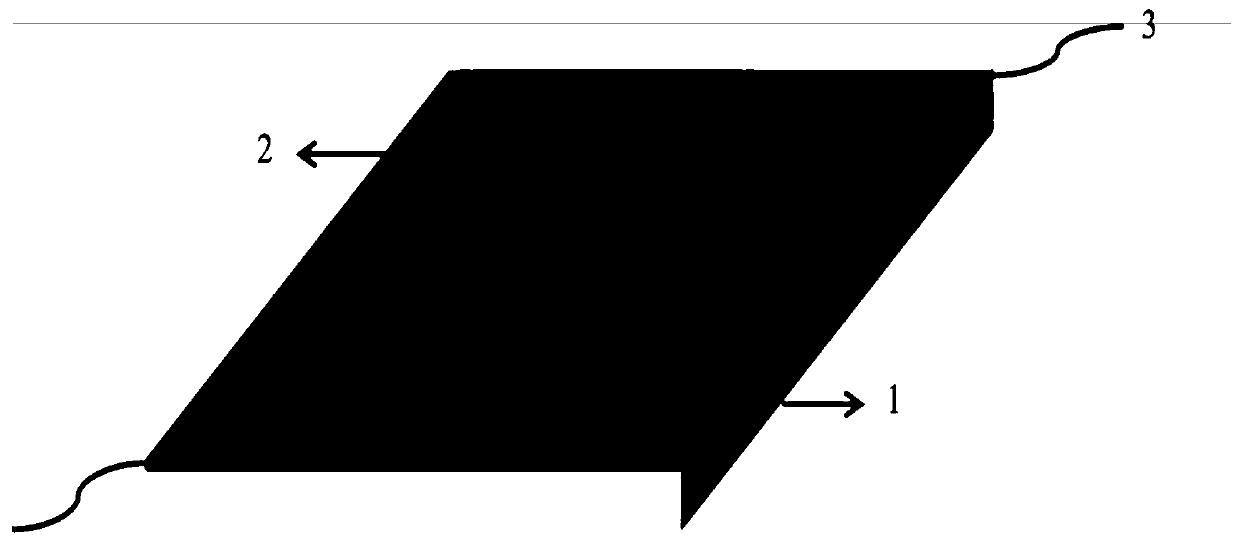

Image

Examples

Embodiment 1

[0032] A polyether ether ketone polymer with a size of about 25mm×20mm×2mm is selected as the base material, and a pure copper coating with a thickness of about 1000 μm is deposited on the surface of the base by a cold spraying process as an electrothermal coating, in which the pure copper powder raw material and the base The pre-processing method is as follows:

[0033] 1. Sieve the copper powder raw material through a 250-400 mesh sieve to make the powder particle size uniform and improve the deposition efficiency. Before spraying, heat preservation at 100-120° C. for 1-2 hours to obtain dry powder that can be sprayed.

[0034] 2. Put the substrate in acetone and ultrasonically clean it for 5 to 10 minutes to remove oil stains, and obtain a substrate with a clean surface after drying.

[0035] The specific process parameters of cold spraying are: the main air pressure of cold spraying is 2MPa, the powder feeding air pressure is 2.2MPa, the main air temperature is 200°C, the...

Embodiment 2

[0040] Select glass with a size of about 25mm×20mm×2mm as the base material, and deposit a pure aluminum coating with a thickness of about 300 μm on the surface of the base as an electrothermal coating. The pretreatment method of the pure aluminum powder raw material and the base is as follows:

[0041] 1. Sieve the powder raw material with a 150-250 mesh sieve to make the powder particle size uniform and improve the deposition efficiency. Before spraying, heat preservation at 100-120° C. for 1-2 hours to obtain sprayable dry powder.

[0042] 2. Put the substrate in acetone and ultrasonically clean it for 5 to 10 minutes to remove oil stains, and obtain a substrate with a clean surface after drying.

[0043] The specific process parameters of cold spraying are as follows: the main air pressure of cold spraying is 2.5MPa, the powder feeding air pressure is 2.2MPa, the main air temperature is 250°C, the spraying powder flow rate is 50g / min, the spraying distance is 30mm, and the...

Embodiment 3

[0048] Alumina with a size of about 25mm×20mm×3mm is selected as the base material, and an aluminum / silicon carbide coating with a thickness of about 500 μm is deposited on the surface of the base as an electrothermal coating, in which silicon carbide powder and aluminum powder raw materials and the base The preprocessing method is as follows:

[0049] 1. Sieve the aluminum powder through a 150-250-mesh sieve; sieve the silicon carbide powder through a 700-900-mesh sieve to make the powder particle size uniform and improve the deposition efficiency. Before spraying, the two are kept at 100-120° C. for 1-2 hours to obtain sprayable dry powder.

[0050] 2. Put the substrate in acetone and ultrasonically clean it for 5 to 10 minutes to remove oil stains, and obtain a substrate with a clean surface after drying.

[0051] The specific process parameters of cold spraying are as follows: the main air pressure of cold spraying is 3MPa, the powder feeding air pressure is 2.2MPa, the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com