Nano composite material based on phosphorus-molybdenum-containing polyoxometallate, preparation method thereof, aptamer sensor and electrode of aptamer sensor

A polyoxometalate, nanocomposite material technology, applied in the field of nanomaterials, can solve the problem of low detection limit, achieve the effect of low detection limit, improve bioaffinity, and excellent reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

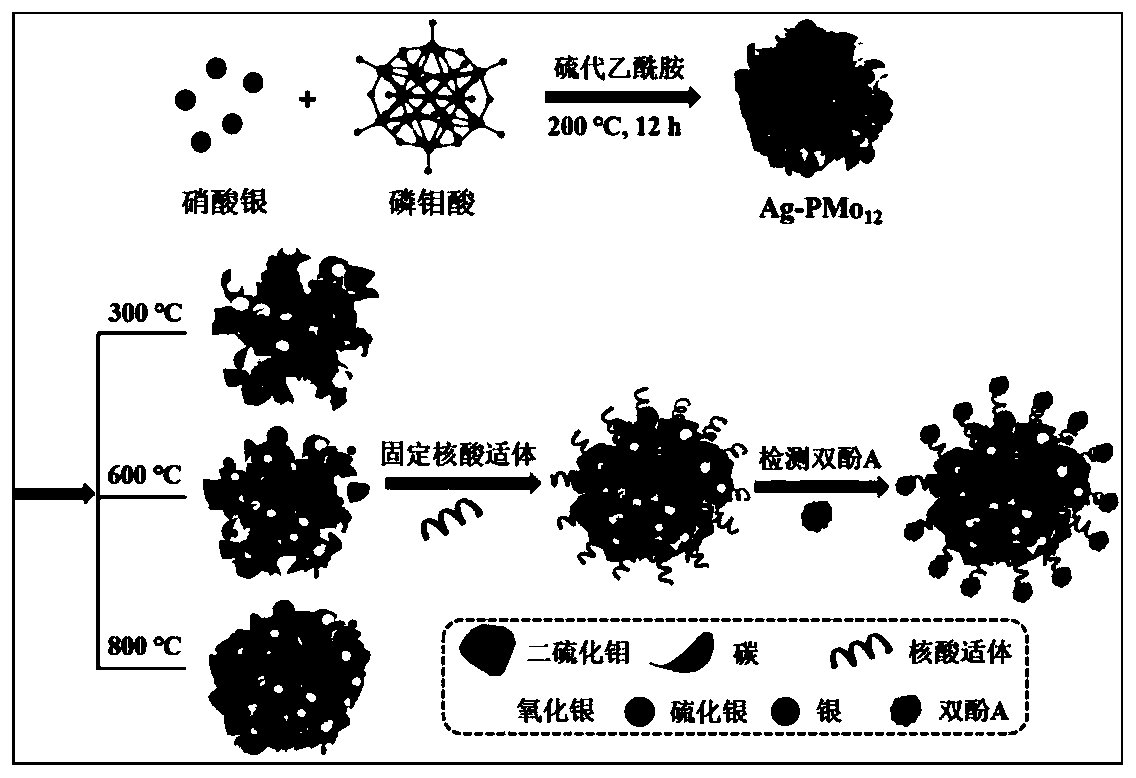

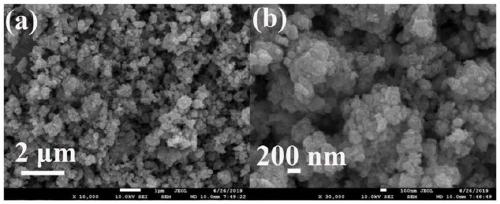

[0084] The nanocomposite material of the present embodiment is made of carbon, molybdenum disulfide nanosheets, nano Ag 2 O particle formation, obtained by calcination of silver-doped molybdenum phosphorus polyoxometalate, after calcination, the organic carbon in the silver-doped molybdenum phosphorus polyoxometalate is transformed into cracked carbon, and the doped silver is transformed into nano-Ag 2 O particles, wherein the silver-doped molybdenum phosphate polyoxometalate is obtained by hydrothermal reaction of silver nitrate, phosphomolybdic acid and thioacetamide.

[0085] The specific steps are:

[0086] (1) Add 50mg of phosphomolybdic acid to 20mL of ultrapure water to prepare solution A, add 1g of AgNO 3 Dissolve in 10mL ultrapure water to make AgNO 3 Solution (0.1g·mL -1 ), take 100 μL of AgNO 3 The solution was added to solution A to obtain solution A', ultrasonically treated for 10 min, and set aside;

[0087] (2) Add 100mg of thioacetamide to 20mL of absolute...

Embodiment 2

[0092] The nanocomposite material of present embodiment comprises carbon, molybdenum disulfide nanosheet and nano Ag 2 O, Ag 2 S particles, obtained by calcination of silver-doped molybdenum phosphorus polyoxometalate, after calcination, the organic carbon in the silver-doped molybdenum phosphorus polyoxometalate is transformed into cracked carbon, and the doped silver is transformed into nano-Ag 2 O, Ag 2 S particles, wherein the silver-doped molybdenum phosphate polyoxometalate is obtained by hydrothermal reaction of silver nitrate, phosphomolybdic acid and thioacetamide.

[0093] The specific steps are:

[0094] (1) Add 50mg of phosphomolybdic acid to 20mL of ultrapure water to prepare solution A, add 1g of AgNO 3 Dissolve in 10mL ultrapure water to make AgNO 3 Solution (0.1g·mL -1 ), take 100 μL of AgNO 3 The solution was added to solution A to obtain solution A', ultrasonically treated for 10 min, and set aside;

[0095] (2) Add 100mg of thioacetamide to 20mL of ab...

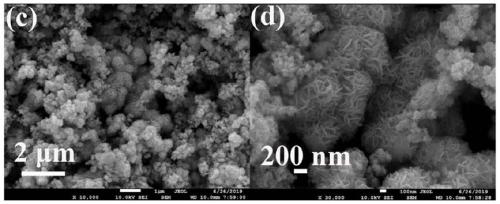

Embodiment 3

[0100] The nanocomposite material of present embodiment comprises carbon, molybdenum disulfide nanosheet and nano Ag 2 O, Ag 2 S, Ag particles, obtained by calcining silver-doped molybdenum phosphorus polyoxometalate, after calcination, the organic carbon in the silver-doped molybdenum phosphorus polyoxometalate is transformed into cracked carbon, and the doped silver is transformed into nano-Ag 2 O, Ag 2 S, Ag particles, wherein the silver-doped molybdenum phosphate polyoxometalate is obtained by hydrothermal reaction of silver nitrate, phosphomolybdic acid and thioacetamide.

[0101] The specific steps are:

[0102] (1) Add 50mg of phosphomolybdic acid to 20mL of ultrapure water to prepare solution A, add 1g of AgNO 3 Dissolve in 10mL ultrapure water to make AgNO 3 Solution (0.1g·mL -1 ), take 100 μL of AgNO 3 The solution was added to solution A to obtain solution A', ultrasonically treated for 10 min, and set aside;

[0103] (2) Add 100mg of thioacetamide to 20mL of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com