Waterborne polyurethane shoe adhesive and preparation method thereof

A technology of water-based polyurethane and shoe glue, which is applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., which can solve problems such as increasing the amount of glue, discontinuous film, and affecting leveling, and achieve reduction The amount of gluing, convenient operation, and the effect of reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

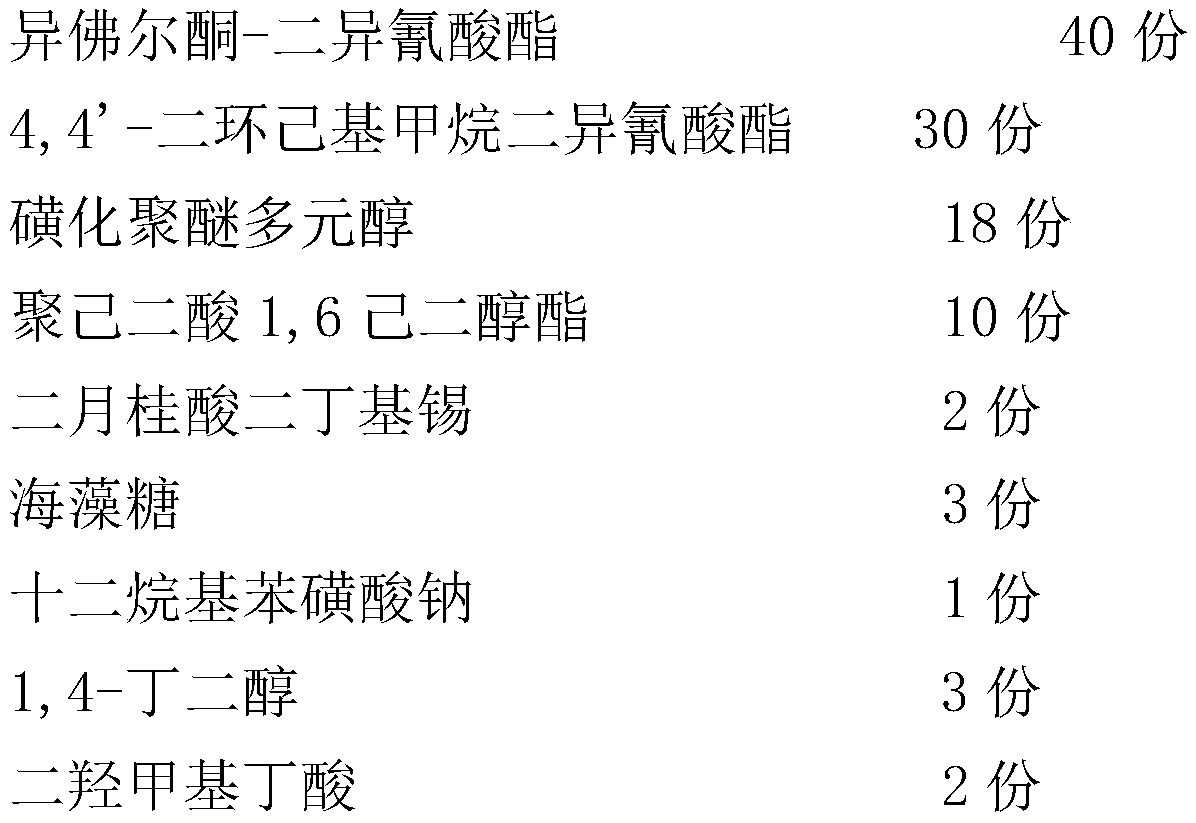

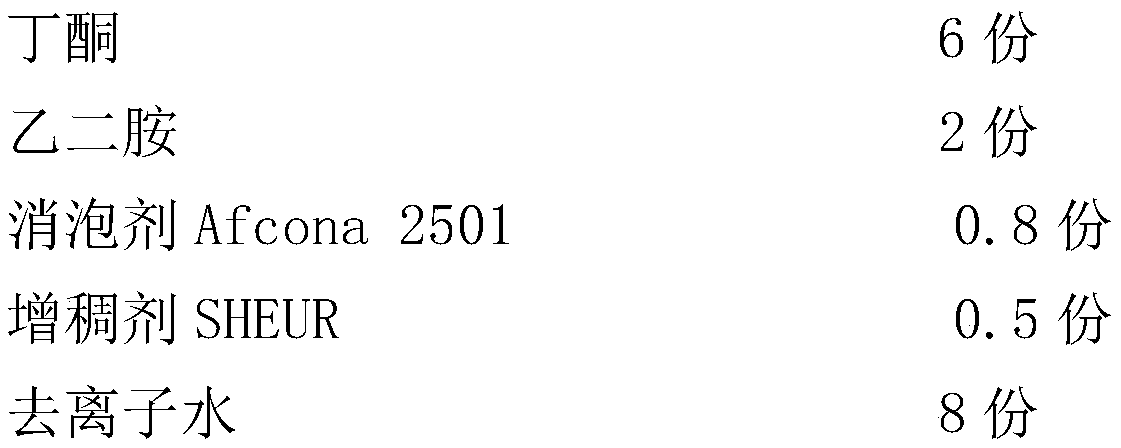

[0023] A kind of water-based polyurethane shoe glue, by weight, comprises following raw material:

[0024]

[0025]

[0026] A preparation method of water-based polyurethane shoe glue, comprising the steps of:

[0027] Add sulfonated polyether polyol and poly-1,6-hexanediol adipate to the polymerization reactor according to the above-mentioned component ratio, raise the temperature to 120°C, distill and remove water for 2 hours under reduced pressure, and cool down to 65°C after the water removal is completed , add isophorone-diisocyanate, 4,4'-dicyclohexylmethane diisocyanate, dibutyltin dilaurate, trehalose, heat up to 90°C, react for 2h; then cool the reaction product to 70°C, add butyl Ketone, after stirring for 10 minutes, add 1,4-butanediol and dimethylol butyric acid, heat up to 90°C, and keep warm for 1h; then cool the reaction product to 35°C, add sodium dodecylbenzenesulfonate and deionized Water, under the condition of the speed of 5000r / min in a high-speed s...

Embodiment 2

[0029] A kind of water-based polyurethane shoe glue, by weight, comprises following raw material:

[0030]

[0031] A preparation method of water-based polyurethane shoe glue, comprising the steps of:

[0032] Add sulfonated polyether polyol and poly(1,6-hexanediol adipate) to the polymerization reactor according to the above-mentioned component ratio, raise the temperature to 110°C, distill and remove water for 2 hours under reduced pressure, and cool down to 60°C after the water removal is completed , add isophorone-diisocyanate, 4,4'-dicyclohexylmethane diisocyanate, dibutyltin dilaurate, trehalose, heat up to 80°C, react for 2h; then cool the reaction product to 60°C, add butyl Ketone, after stirring for 10 minutes, add 1,4-butanediol and dimethylol butyric acid, heat up to 80°C, and keep warm for 1h; then cool the reaction product to 30°C, add sodium dodecylbenzenesulfonate and deionized Water, under the condition of the speed of 4500r / min in a high-speed shear mixer,...

Embodiment 3

[0034] A kind of water-based polyurethane shoe glue, by weight parts, comprises following raw material:

[0035]

[0036] A preparation method of water-based polyurethane shoe glue, comprising the steps of:

[0037] Add sulfonated polyether polyol and poly-1,6-hexanediol adipate to the polymerization reactor according to the above component ratio, raise the temperature to 120°C, distill and remove water for 2 hours under reduced pressure, and cool down to 70°C after the water removal is completed , add isophorone-diisocyanate, 4,4'-dicyclohexylmethane diisocyanate, dibutyltin dilaurate, trehalose, heat up to 100°C, react for 2h; then cool the reaction product to 70°C, add butyl Ketone, after stirring for 10 minutes, add 1,4-butanediol and dimethylol butyric acid, heat up to 90°C, and keep warm for 1h; then cool the reaction product to 40°C, add sodium dodecylbenzenesulfonate and deionized Water, under the condition of the speed of 5000r / min in a high-speed shear mixer, she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com