Composition for assisting in improving moisture permeability of polyurethane and polyurethane hot melt adhesive containing composition

A polyurethane hot melt adhesive and moisture permeability technology, applied in the field of polyurethane hot melt adhesives, can solve the problems of low moisture permeability of polyurethane hot melt adhesives, and achieve the effects of improving peel strength, accelerating PUR curing, and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

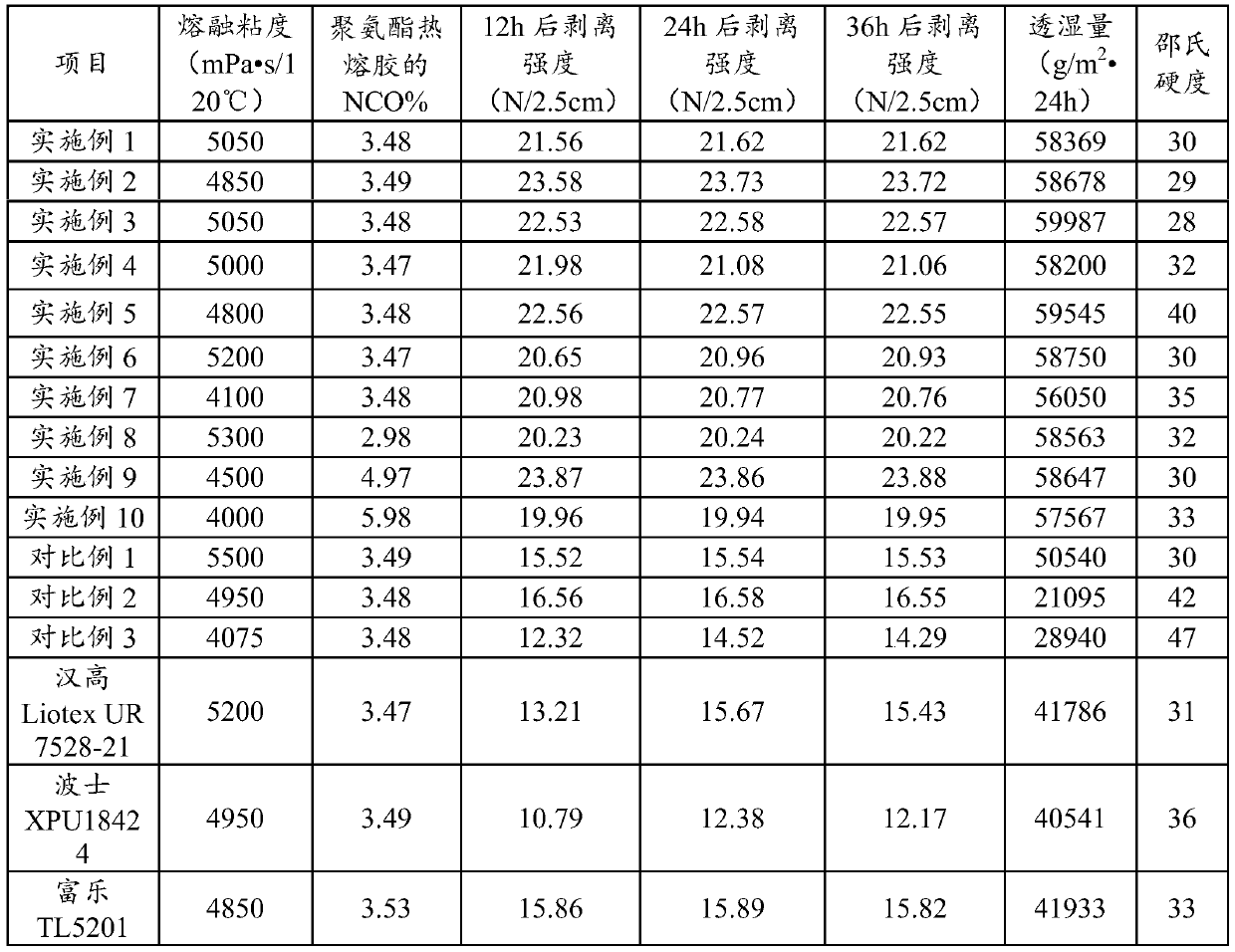

Examples

Embodiment 1

[0048] This example provides a composition to help improve the moisture permeability of polyurethane, including 8g of polyoxypropylene diol with a number average molecular weight of 1000, 32g of polyoxypropylene diol with a number average molecular weight of 2000, a mass ratio of EO to PO of 3:1, and EO end capping 40% polyether polyol, 20 g polyneopentyl phthalate diol and 10 g poly-3-methyl-1,5-pentanediol adipate diol.

[0049] Wherein, the polyether polyol of the present embodiment is made by the following method: (1) 530.6g starter diethylene glycol and 50g catalyst potassium hydroxide are added in the normal-pressure stainless steel reactor and stirred and melted, and the melting temperature 80°C, then vacuum decompression, dehydration at 115°C, 1330Pa for 2 hours, stop dehydration when the water content reaches 0.3%, and obtain a potassium alkoxide solution. (2) Introduce nitrogen into the stainless steel reactor to replace the oxygen contained in it, so that the oxygen...

Embodiment 2

[0054] This example provides a composition that assists in improving the moisture permeability of polyurethane, including 8 g of polyoxypropylene diol with a number average molecular weight of 1000, 32 g of polyoxypropylene diol with a number average molecular weight of 2000, a mass ratio of EO to PO of 5:1, and EO-capped 55% polyether polyol, 20 g polyneopentyl phthalate diol and 10 g poly-3-methyl-1,5-pentanediol adipate diol.

[0055] Wherein, the polyether polyol of the present embodiment is made by the following method: (1) 530.6g starter diethylene glycol and 50g catalyst potassium hydroxide are added in the normal-pressure stainless steel reactor and stirred and melted, and the melting temperature 80°C, then vacuum decompression, dehydration at 115°C, 1330Pa for 2 hours, stop dehydration when the water content reaches 0.3%, and obtain a potassium alkoxide solution. (2) Pass nitrogen into the stainless steel reaction kettle to replace the oxygen contained in it, so that ...

Embodiment 3

[0060] This example provides a composition that assists in improving the moisture permeability of polyurethane, including 8 g of polyoxypropylene diol with a number average molecular weight of 1000, 32 g of polyoxypropylene diol with a number average molecular weight of 2000, a mass ratio of EO to PO of 9:1, and EO-capped 87% polyether polyol, 20 g polyneopentyl phthalate diol and 10 g poly-3-methyl-1,5-pentanediol adipate diol.

[0061] Wherein, the polyether polyol of the present embodiment is made by the following method: (1) 530.6g starter diethylene glycol and 50g catalyst potassium hydroxide are added in the normal-pressure stainless steel reactor and stirred and melted, and the melting temperature 80°C, then vacuum decompression, dehydration at 115°C, 1330Pa for 2 hours, stop dehydration when the water content reaches 0.3%, and obtain a potassium alkoxide solution. (2) Pass nitrogen into the stainless steel reaction kettle to replace the oxygen contained therein, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com