High-toughness halogen-free cyanate ester resin composite material and preparation method thereof

A resin composite material and cyanate resin technology are applied in the field of high toughness halogen-free cyanate resin composite material and its preparation, and achieve the effects of good flame retardant performance, not easy to foam, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

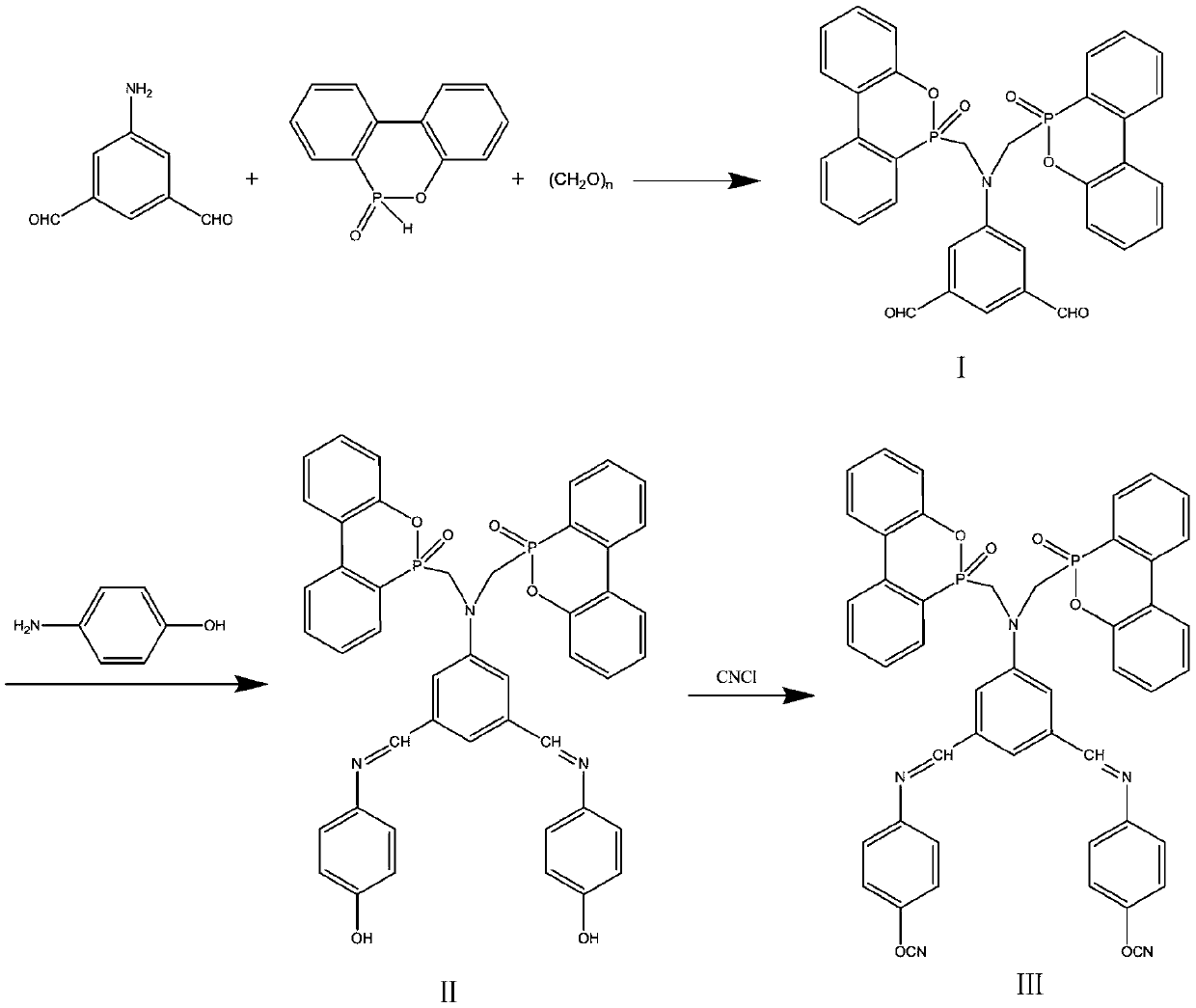

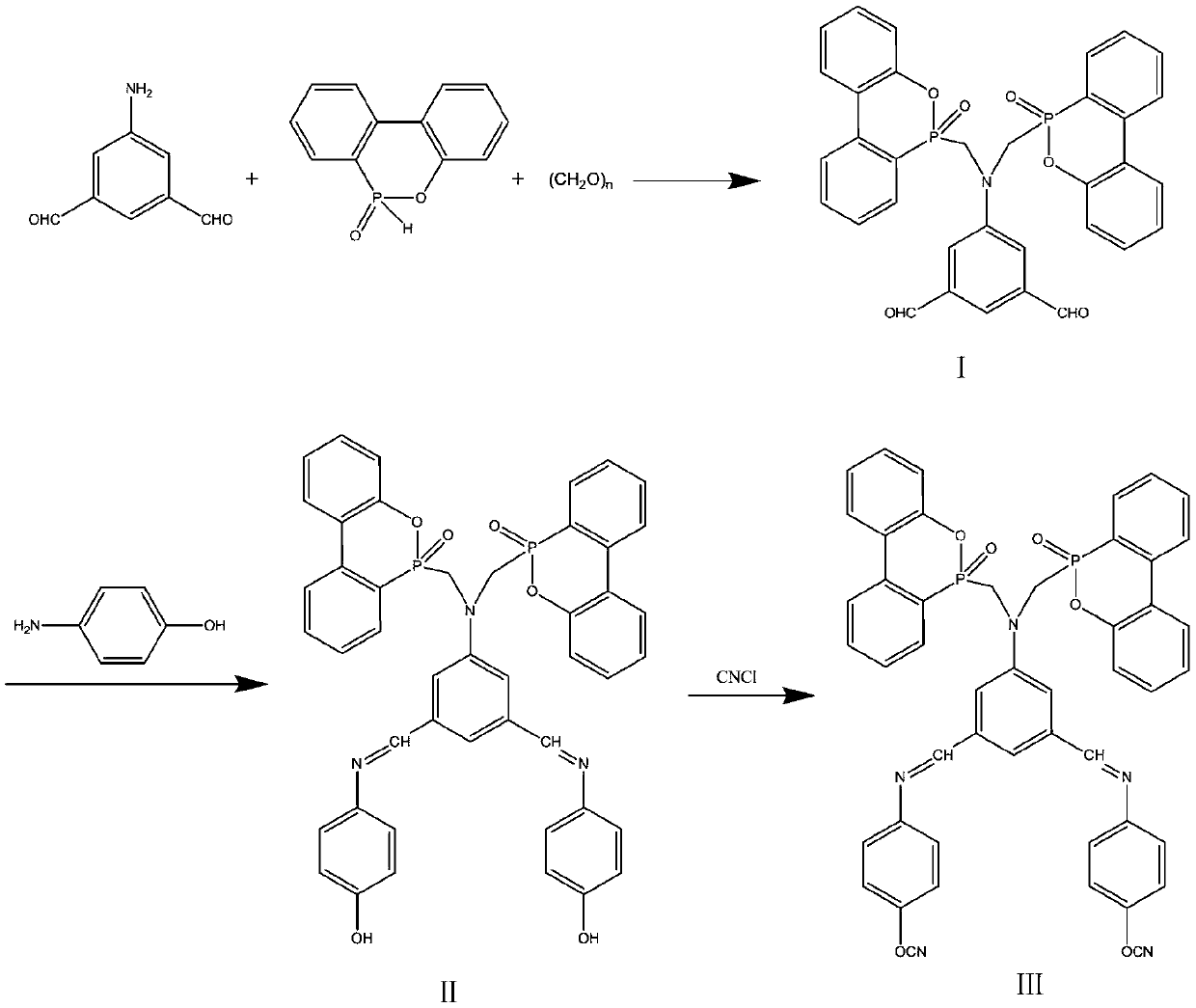

Method used

Image

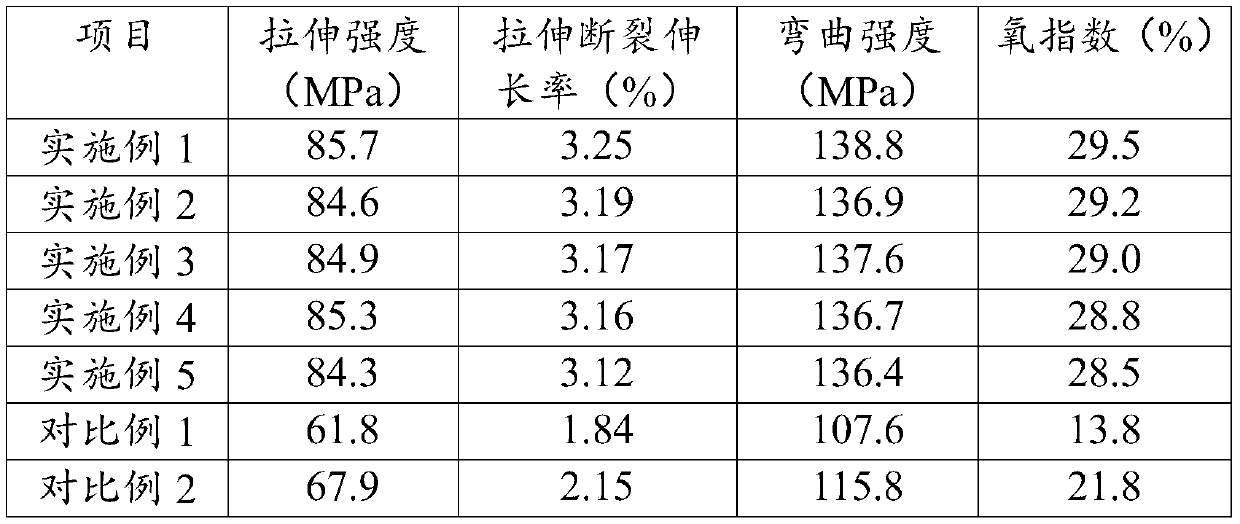

Examples

Embodiment 1

[0030] A high-toughness halogen-free cyanate resin composite material, prepared from modified cyanate resin, carbon nanotubes, and surfactants, wherein the carbon nanotubes are uniformly dispersed in the cyanate resin, wherein the modified cyanate The mass ratio of the resin in the composite material is 99.4%, and the mass ratio of the surfactant to the carbon nanotube is 0.5:1; Carbon nanotubes are mixed according to the mass ratio of 1.4:1. The surfactant is a mixture of octylphenol polyoxyethylene ether and high-carbon fatty alcohol polyoxyethylene ether in a mass ratio of 1:1.

[0031] The preparation method of modified cyanate ester resin is as follows:

[0032] S1. Add 149g (1mol) of 5-amino-m-benzaldehyde, 518.4g (2.4mol) of DOPO, 84g (2.8mol) of paraformaldehyde and 2384g of N, N-dimethylformamide in the three-necked flask, and heat up to 157 ℃, reflux and stir the reaction for 11 hours, let it stand until the solid precipitates, filter under reduced pressure, wash t...

Embodiment 2

[0039] A high-toughness halogen-free cyanate resin composite material, prepared from modified cyanate resin, carbon nanotubes, and surfactants, wherein the carbon nanotubes are uniformly dispersed in the cyanate resin, wherein the modified cyanate The mass ratio of the resin in the composite material is 99.4%, and the mass ratio of the surfactant to the carbon nanotube is 0.52:1; Carbon nanotubes are mixed according to the mass ratio of 1.5:1. The surfactant is octylphenol polyoxyethylene ether.

[0040] The preparation method of modified cyanate ester resin is as follows:

[0041] S1. Add 149g (1mol) of 5-amino-m-benzaldehyde, 496.8g (2.3mol) of DOPO, 93g (3.1mol) of paraformaldehyde and 2682g of N,N-dimethylformamide to a three-necked flask, and heat up to 158 ℃, reflux and stir the reaction for 11.5 hours, let it stand until the solid precipitates, filter under reduced pressure, wash the filter cake 3 times with ethyl acetate, concentrate under reduced pressure and recrys...

Embodiment 3

[0048] A high-toughness halogen-free cyanate resin composite material, prepared from modified cyanate resin, carbon nanotubes, and surfactants, wherein the carbon nanotubes are uniformly dispersed in the cyanate resin, wherein the modified cyanate The mass ratio of the resin in the composite material is 99.2%, and the mass ratio of the surfactant to the carbon nanotube is 0.6:1; Carbon nanotubes are mixed according to the mass ratio of 1.5:1. The surfactant is high-carbon fatty alcohol polyoxyethylene ether.

[0049] The preparation method of modified cyanate ester resin is as follows:

[0050] S1. Add 149g (1mol) of 5-amino-m-benzaldehyde, 518.4g (2.4mol) of DOPO, 81g (2.7mol) of paraformaldehyde and 2086g of N,N-dimethylformamide to a three-necked flask, and heat up to 160 ℃, reflux and stir the reaction for 12 hours, let stand until the solid precipitates, filter under reduced pressure, wash the filter cake 3 times with ethyl acetate, concentrate under reduced pressure an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com