High-adhesion water-based ink and preparation method thereof

A technology of water-based ink and water-based dispersant, which is applied in ink, application, household utensils, etc. It can solve the problems of poor resistance to ethanol scrubbing, low adhesion, and slow surface drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

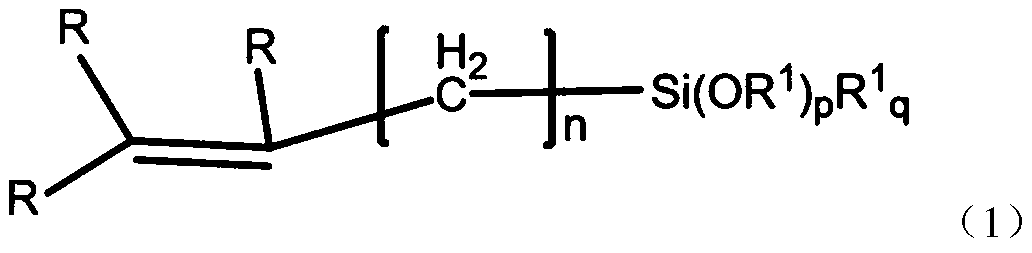

[0071] Preparation Example 1: Preparation of Modified Nano-Silica Particles

[0072] A mixed solution of absolute ethanol and water is prepared in a volume ratio of 1:1. Silica particles with a particle size of 30 nm rich in hydroxyl groups on the surface were dispersed uniformly in the above mixed solution by ultrasonic waves, an equal weight of trimethoxyvinylsilane was added to the silica particles, and the mixture was stirred at a constant temperature of 60° C. for 10 hours. The obtained emulsion is centrifuged at high speed to remove excess organosiloxane and by-products, and dried to obtain modified nano-silica particles.

preparation example 2

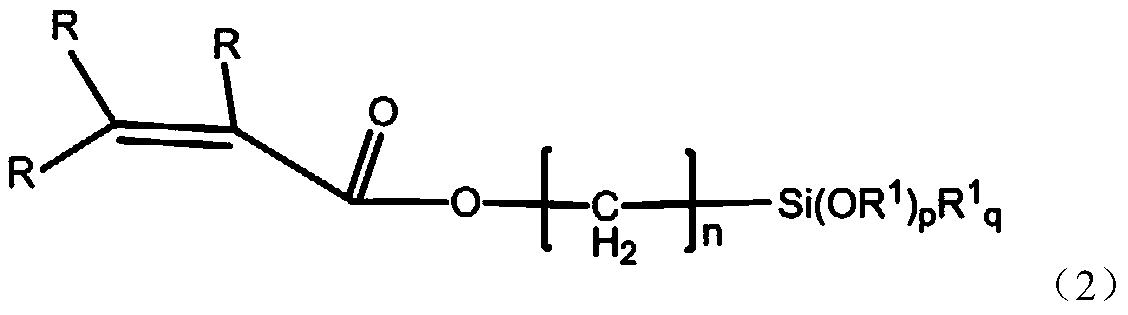

[0073] Preparation Example 2: Preparation of Modified Nano-Silica Particles

[0074] A mixed solution of absolute ethanol and water is prepared in a volume ratio of 1:1. The silica particles with a particle size of 20 nm rich in hydroxyl groups on the surface were dispersed uniformly by ultrasonic in the above mixed solution, and an equal weight of acryloxypropyltrimethoxysilane was added to the silica particles, and stirred at a constant temperature of 80 °C for 8 hours. . The obtained emulsion is centrifuged at high speed to remove excess organosiloxane and by-products, and dried to obtain modified nano-silica particles.

preparation example 3

[0075] Preparation example 3: Preparation of nano-silica modified core-shell self-crosslinking emulsion

[0076] 0.64g of emulsifier DSB produced by Rhodia, 100g of deionized water, 3g of modified nano-silica particles prepared in Preparation Example 1, 3g of glycidyl acrylate, 78g of methyl methacrylate, 16g The butyl acrylate was stirred uniformly at room temperature to obtain a core pre-emulsion; 0.64g of emulsifier DSB produced by Rhodia, 100g of deionized water, 4g of trimethoxyvinylsilane, 3g of acrylic acid, 15.5g of methyl methacrylate were mixed. Methyl acrylate, 77.5 g of isooctyl acrylate, and uniformly stirred at room temperature to obtain a shell pre-emulsion.

[0077] in N 2 Under the atmosphere, in the reactor equipped with thermometer, stirring device, reflux cooler, add 266g water, the emulsifier DSB produced by 1.72g Rhodia company (Rhodia), 0.5g sodium bicarbonate, 40g core pre-emulsion, Aqueous solution containing 0.1 g of sodium persulfate, stir well. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com