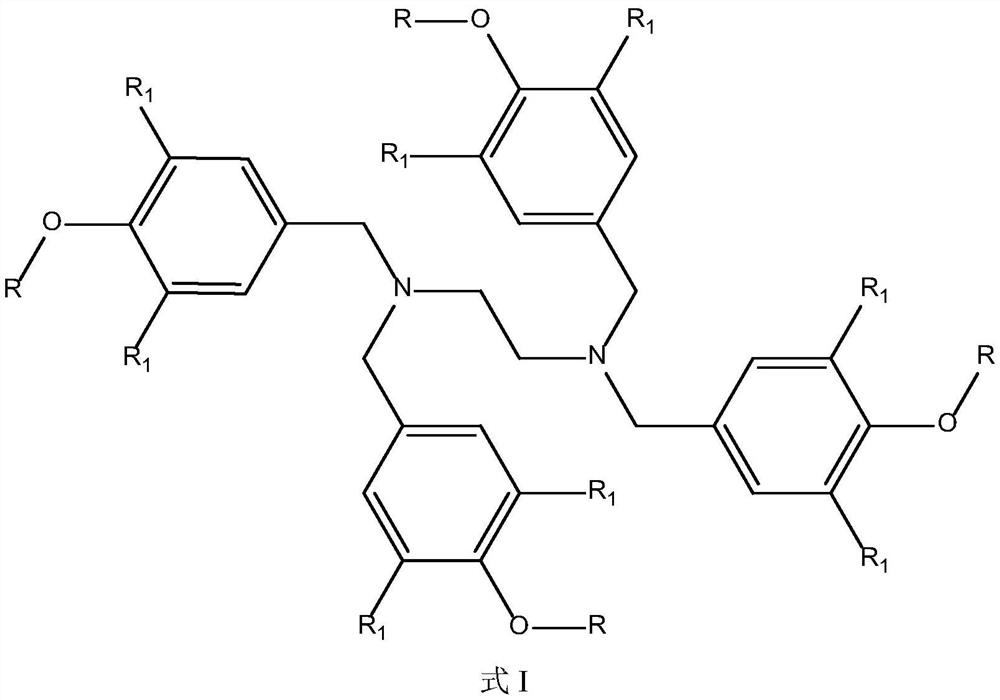

A kind of demulsifier and its preparation method and application

A technology of demulsifier and polymerization reaction, which is applied in the direction of dehydration/demulsification by chemical methods, and can solve the problems that affect the normal operation of the sewage treatment system, low molecular weight, and slow dehydration speed that affect the quality of crude oil exported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

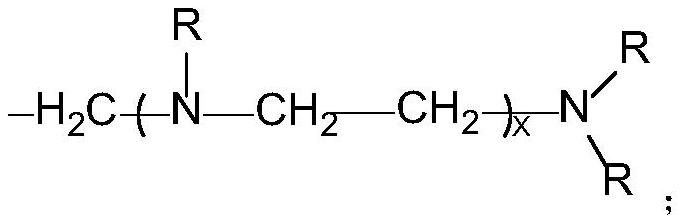

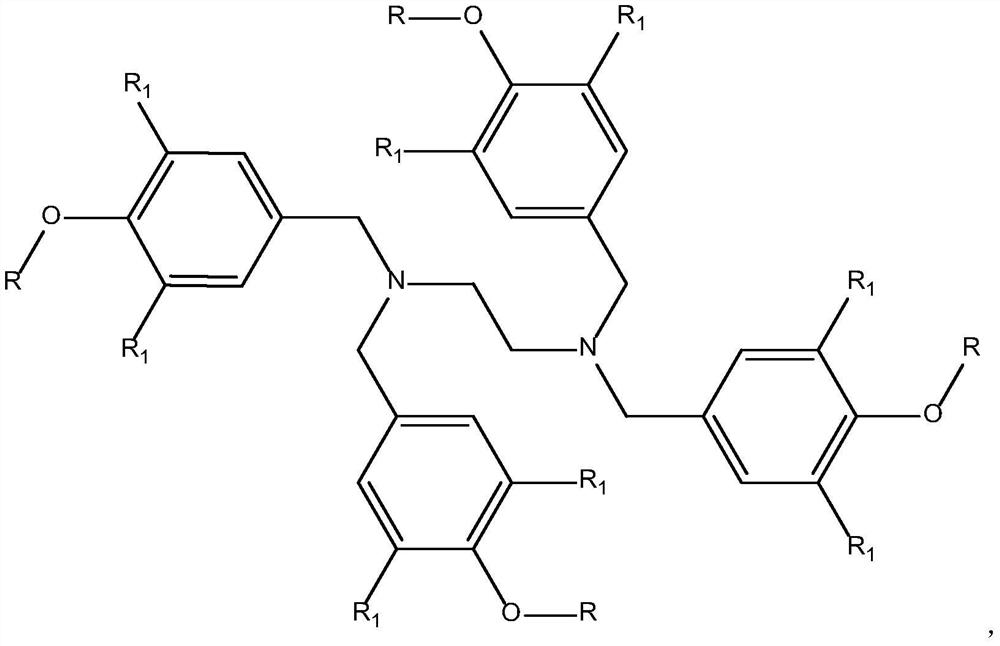

Method used

Image

Examples

Embodiment 1

[0041] The preparation method of the demulsifier of the present embodiment may further comprise the steps:

[0042] 1) Put 350g of formaldehyde solution with a mass concentration of 37% in a three-necked flask, add dropwise a NaOH solution with a mass concentration of 10%, adjust the pH value to 8.5, heat up to 50°C and stir, and add ethylenediamine dropwise into the there-necked flask 60g (the molar ratio of formaldehyde and ethylenediamine is 4.3:1), after the dropwise addition, the temperature was raised to 80°C for 2 hours, and then the temperature was lowered to 60°C for vacuum drying to remove moisture and unreacted formaldehyde to obtain ethylenediamine aldehyde;

[0043] 2) Add 396g of phenol into the there-necked flask, add dropwise HCl solution with a mass concentration of 18%, adjust the pH value to 4, raise the temperature to 70°C, and add all the ethylenediamine aldehyde prepared in step 1) dropwise into the phenol (The molar ratio of phenol to ethylenediamine ald...

Embodiment 2

[0056] The preparation method of the demulsifier of the present embodiment may further comprise the steps:

[0057] 1) According to the step 1)~2) of embodiment 1, prepare ethylenediamine aldehyde phenol; Get 55g ethylenediamine aldehyde phenol and 172g tetraethylenepentamine and drop in the three-necked flask (the mole of ethylenediamine aldehyde phenol and tetraethylenepentamine ratio of 1:8), at 60°C, dropwise add 74g of formaldehyde solution with a mass concentration of 37% (the molar ratio of ethylenediamine aldehyde phenol to formaldehyde is 1:8), and slowly raise the temperature to 90°C for 1 hour, then raise the temperature to 120 ℃ for 2 hours, lower the temperature, and vacuum-dry the product to obtain a brown-yellow viscous ethylenediamine-modified phenolamine resin;

[0058] 2) Take ethylenediamine-modified phenolamine resin 6g as the initiator and catalyst KOH 3g and add it to the autoclave, seal the autoclave and test the pressure, and use dry nitrogen to displac...

Embodiment 3

[0068] The preparation method of the demulsifier of the present embodiment may further comprise the steps:

[0069] 1) Prepare ethylenediamine-modified phenolamine resin diblock polyether according to steps 1) to 4 of Example 1;

[0070] 2) Take 80g of ethylenediamine-modified phenolic amine resin diblock polyether, 9g of zinc acetate, 240g of acrylic acid, 160g of maleic anhydride, and 40g of toluene, and add them to the four ports of the reflux condenser, stirrer, and thermometer with a water separator. In the flask, after replacing the air with nitrogen, heat and stir, and reflux at 120°C for 6 hours;

[0071] Then cool down to 60°C, add 4g of dioctyl peroxydicarbonate (EHP), raise the temperature to 70°C, continue the reaction for 1.5h, then cool down to 30°C, and discharge to obtain acrylic acid maleic anhydride modified high-efficiency demulsifier.

[0072] Examples of demulsifiers

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com