Method for determining content of nickel in ferro-nickel alloy and sample preparation process thereof

A technology for the determination of nickel content and nickel-iron alloy, which is applied in the field of analysis and detection, can solve problems such as environmental pollution, and achieve the effects of avoiding pollution, high efficiency and no sample.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

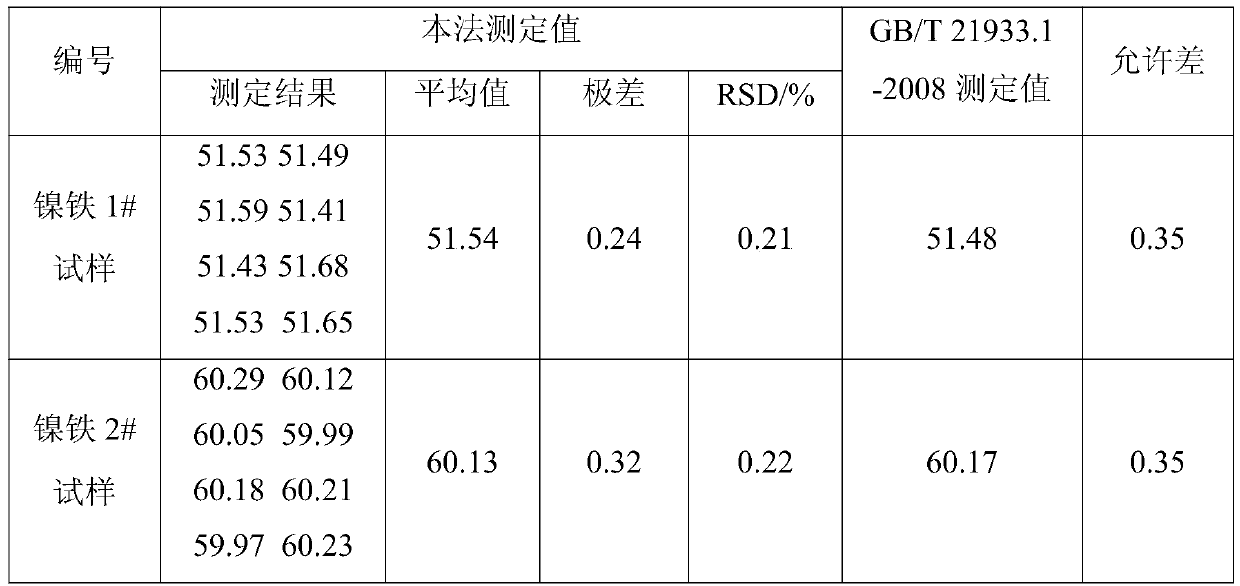

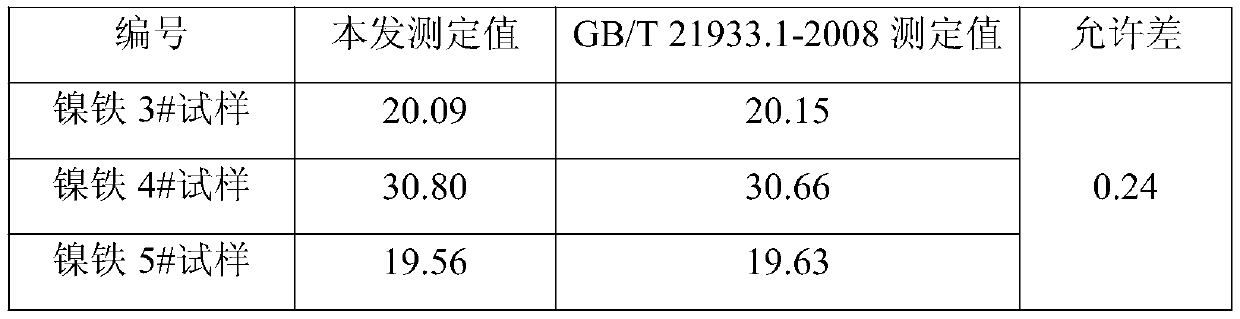

Examples

Embodiment 1

[0045] Embodiment 1: iron crucible primary melting method measures the nickel content in the ferronickel alloy

[0046] 1. Sample melting is completed through the following steps:

[0047] A. Accurately weigh 0.400g (accurate to 0.1mg) nickel-iron standard sample (particle size ≤ 0.125mm) into a 50mL iron crucible pre-added with about 2g of sodium peroxide, then add about 2g of sodium peroxide to cover the surface of the sample.

[0048] B. Move the crucible into a high-temperature furnace at 600°C, heat it until it melts, then raise the temperature to 700°C, melt at this temperature for 10 minutes, and take out the crucible to cool to room temperature.

[0049] 2. The determination of nickel content is completed by the following steps

[0050] C. Put the crucible into a beaker filled with an appropriate amount of water in advance, cover it with a watch glass and leaching until the melt is completely leached; wash the crucible with water, take it out, and slowly add hydrochlo...

Embodiment 2

[0057] Embodiment 2: Determination of nickel content in nickel-iron alloy by corundum crucible secondary melting method

[0058] 1. Sample melting is completed through the following steps

[0059] A. Accurately weigh 0.300g (accurate to 0.1mg) nickel-iron sample (particle size ≤ 0.0.180mm, that is, all samples pass through 80 mesh sieve) in a 30mL corundum crucible pre-added with about 2g of sodium peroxide, and then Add about 2g of sodium peroxide to cover the surface of the sample.

[0060] B. Move the crucible into a high-temperature furnace at 680°C, melt sodium peroxide at this temperature, then heat up to 800°C for 20 minutes, and take out the crucible to cool to room temperature.

[0061] C. Put the crucible into a beaker filled with 50mL water in advance, cover it with a watch glass and leaching until the melt is completely leached; wash the crucible with water, take out the crucible, and slowly add hydrochloric acid dropwise to the test solution until the test soluti...

Embodiment 3

[0071] Embodiment 3: Determination of nickel content in nickel-iron alloy by high-alumina crucible once-melting method

[0072] A. Accurately weigh 0.200g (accurate to 0.1mg) nickel-iron sample (particle size ≤ 0.0.180mm, that is, all samples pass through 80 mesh sieve) in a 30mL high-alumina crucible pre-added with about 2g of sodium peroxide, Then add about 3g of sodium peroxide to cover the surface of the sample.

[0073] B. Move the crucible into a high-temperature furnace at 680°C, melt sodium peroxide at this temperature, then heat up to 820°C and melt for 25 minutes, and take out the crucible to cool to room temperature.

[0074] C. Put the crucible into a beaker filled with 50mL water in advance, cover with a watch glass and leaching until the molten material is leaching completely. Wash the crucible with water, take out the crucible, slowly add hydrochloric acid dropwise to the test solution until the test solution is clear (pH is about 2.5), transfer the test soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com