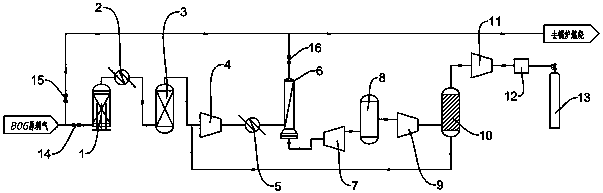

Equipment and process for extracting helium from BOG gas with high hydrogen content

A technology of hydrogen content and helium, applied in gas treatment, inert gas compounds, inorganic chemistry, etc., can solve the problems of unfavorable reaction control, temperature rise, large floor area, etc., to reduce equipment investment and operating costs, High yield and purity, effect of increased recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] Embodiment: according to specification figure 1 It can be seen that when in use, when the BOG helium extraction device is put into use, close the hand valve 15 of the BOG feed gas to remove the fuel gas pipe network, open the BOG feed gas to remove the hand valve 14 of the helium device, and open the non-permeable gas of the membrane separator to remove the BOG fuel gas Hand valve 16, the BOG helium purification system is put into use. When the BOG helium purification system is overhauled, open the BOG feed gas to fuel gas pipe network hand valve 15, close the BOG feed gas to helium extraction device hand valve 14, and close the membrane separator non- The permeate gas goes to the BOG fuel gas hand valve 16, and the BOG fuel gas pipeline network can supply gas normally without affecting the use of subsequent users.

[0034]The BOG raw material gas from the original BOG fuel gas pipeline network is mixed with excess air and then enters the catalytic dehydrogenation react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com