Method for preparing colorless isopropanol from organic cleaning waste liquid of electronic factory

An isopropanol and electronic factory technology, applied in the preparation of organic compounds, organic chemistry, chemical instruments and methods, etc., can solve the problems of increasing the cost of semiconductor manufacturing, high cost of reverse osmosis membranes, difficult recycling and processing, etc., and achieve good exposure. The effect of removing gas, improving resource utilization rate, and high product value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

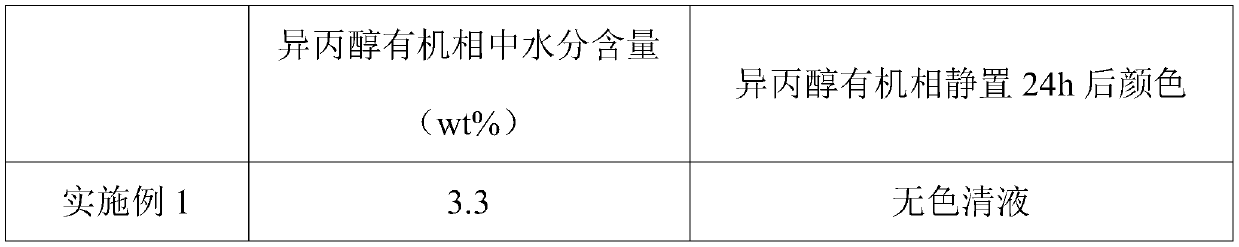

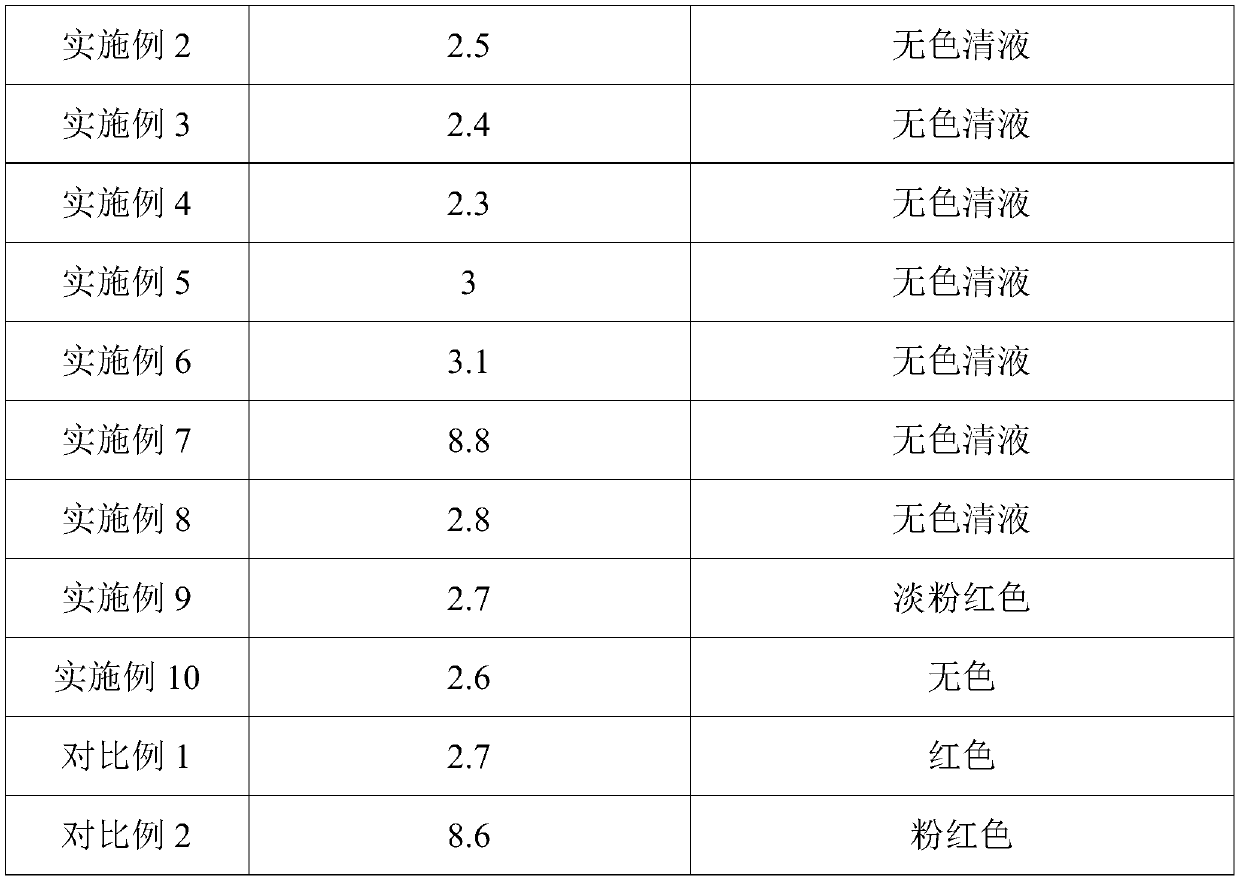

Examples

Embodiment 1

[0059] The present embodiment provides a method for preparing colorless isopropanol from organic cleaning waste liquid of electronic factory, and the method comprises the following steps:

[0060] (1) Get 200mL of organic cleaning waste liquid (EKC) produced by a known electronic factory, the mass concentration of isopropanol in the waste liquid is 48wt%, and the mass concentration of catechol is 2wt%;

[0061] The waste liquid is distilled at -0.005MPa and 120°C to obtain the isopropanol fraction containing catechol. The waste liquid after distillation has complex components and is directly incinerated;

[0062] (2) Get 50mL of the isopropanol fraction (water of 42wt%, all the other are organic components, the content of isopropanol in the organic components is 98wt%) and join in the distillation unit with reflux condensation, add aeration stone, Introduce air and heat at 80°C for 2 hours to remove catechol and obtain isopropanol solution;

[0063] (3) Add 15g potassium fluo...

Embodiment 2

[0065] The present embodiment provides a method for preparing colorless isopropanol from organic cleaning waste liquid of electronic factory, and the method comprises the following steps:

[0066] (1) Get 200mL of organic cleaning waste liquid (EKC) produced by a known electronic factory, the mass concentration of isopropanol in the waste liquid is 43wt%, and the mass concentration of catechol is 1wt%;

[0067] The waste liquid is distilled at -0.005MPa and 120°C to obtain the isopropanol fraction containing catechol. The waste liquid after distillation has complex components and is directly incinerated;

[0068] (2) Get 50mL of the isopropanol fraction (water of 40wt%, all the other are organic components, the content of isopropanol in the organic components is 99wt%) and join in the distillation unit with reflux condensation, add aeration stone, Introduce air and heat at 80°C for 4 hours to remove catechol and obtain isopropanol solution;

[0069] (3) Add 20g potassium fluo...

Embodiment 3

[0071] The present embodiment provides a method for preparing colorless isopropanol from organic cleaning waste liquid of electronic factory, and the method comprises the following steps:

[0072] (1) Get 200mL of organic cleaning waste liquid (EKC) produced by a known electronic factory, the mass concentration of isopropanol in the waste liquid is 38wt%, and the mass concentration of catechol is 2wt%;

[0073] The waste liquid is distilled at -0.005MPa and 115°C to obtain a catechol-containing isopropanol fraction. The waste liquid after distillation has complex components and is directly incinerated;

[0074] (2) Get 50mL of the isopropanol fraction (water of 40wt%, all the other are organic components, the content of isopropanol in the organic component is 98wt%) and join in the distillation unit with reflux condensation, add aeration stone, Introduce air and heat at 80°C for 3 hours to remove catechol and obtain isopropanol solution;

[0075] (3) Distill and concentrate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com