Preparation method and application of sodium tetraphenylethylene disulfonate

A technology of sodium bissulfonate and tetraphenylethylene, which is applied in the field of protein detection and sodium tetrastyryl disulfonate, can solve the problems of complex synthesis steps, poor water solubility, high cost, etc., and achieve good water solubility and fluorescence intensity Effect of Enhanced, Good Aggregation-Induced Luminescent Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

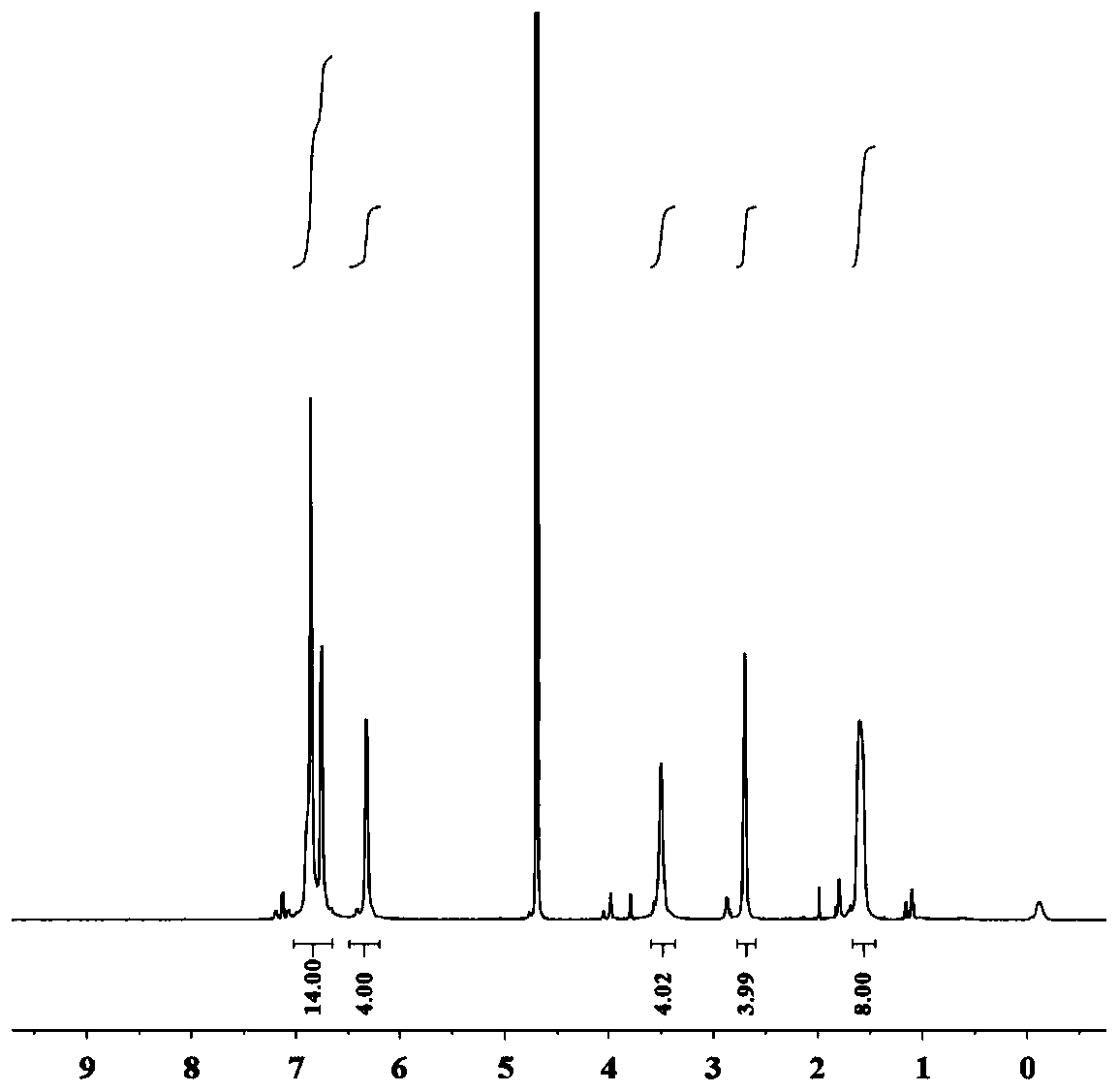

[0026] Embodiment 1: Preparation of TPE-diSS (tetrastyryl disulfonic acid sodium salt)

[0027] (1) Weigh 0.46g (2.5mmol) of benzophenone and 1.64g (25mmol) of zinc powder, add them to a 100mL two-necked round-bottomed flask equipped with a stirring magnet, and put a rubber Stopper, the other bottle mouth is connected with a double row tube, start vacuuming operation, and feed nitrogen, these two operations are repeated 3 times. Dissolve 0.54g (2.5mmol) of 4,4'-dihydroxybenzophenone in 37.5mL of anhydrous tetrahydrofuran and add it to a two-necked round-bottomed flask, mix ethyl acetate and liquid nitrogen to create a low-temperature environment, and keep the temperature at -10°C, slowly add 2.36g (12.5mmol) of TiCl dropwise under stirring condition 4 , remove the ice bath device, wait for the temperature to rise to room temperature, after reacting at room temperature for 0.5h, slowly raise the temperature to 75°C, and the reaction time is 12h. After the reaction was complet...

Embodiment 2

[0033] Embodiment 2: Optical property test of TPE-diSS

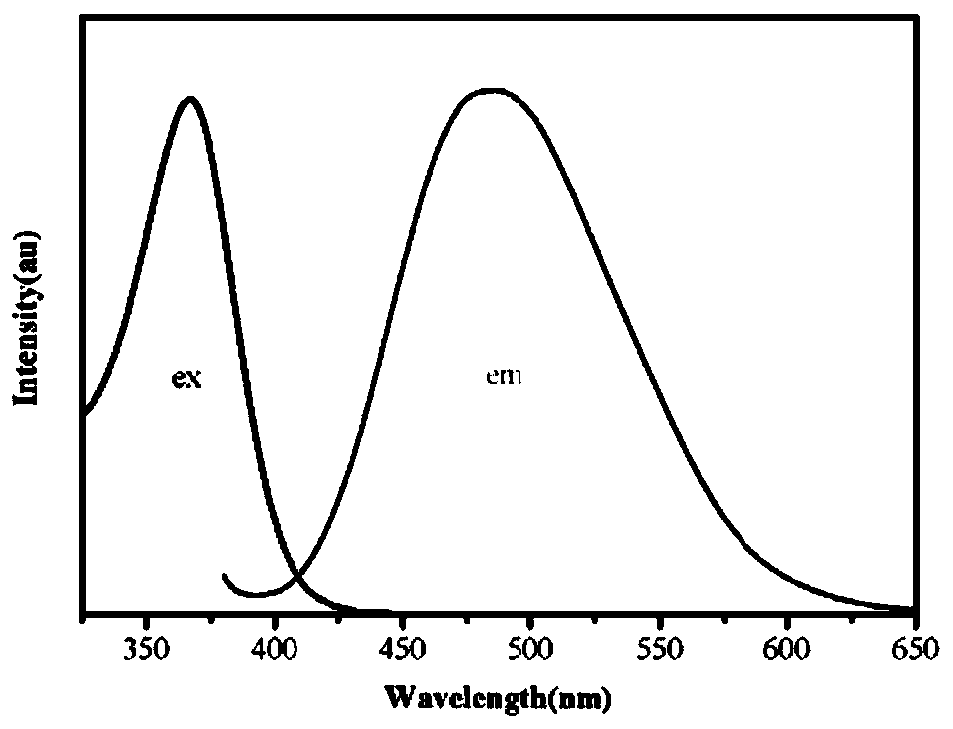

[0034] Configure 0.5mM TPE-diSS aqueous solution, measure its excitation spectrum and fluorescence emission spectrum, such as figure 2 As shown, the maximum excitation wavelength is at 365nm, and the molecule has a strong fluorescence emission peak at 485nm after being excited.

Embodiment 3

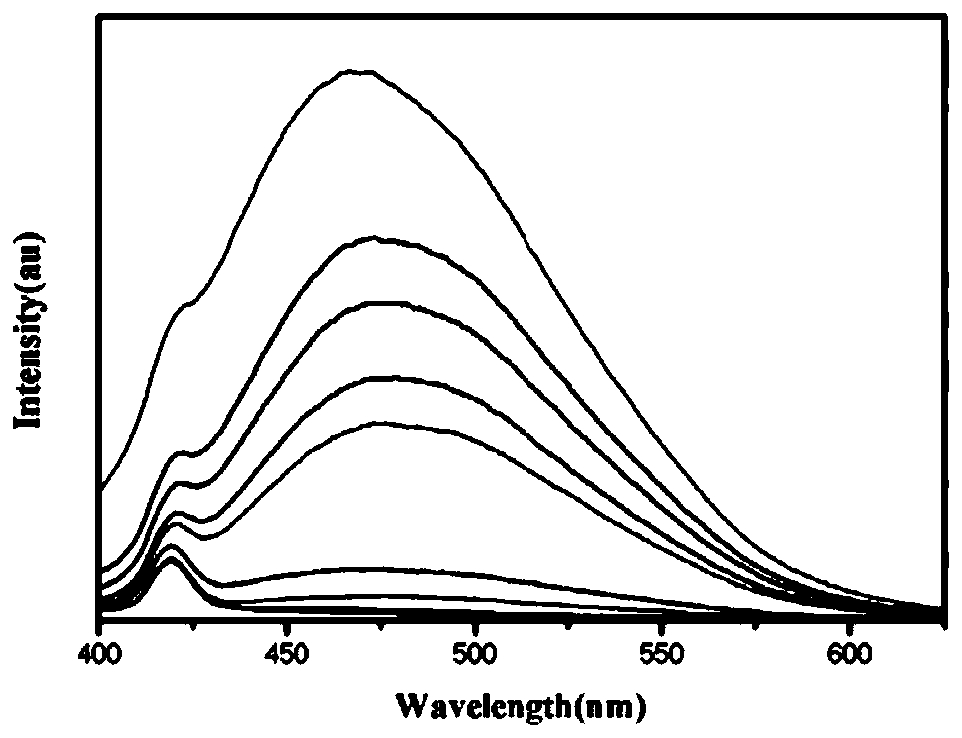

[0035] Example 3: Fluorescent detection of BSA in aqueous solution by TPE-diSS

[0036] A. Prepare TPE-diSS and BSA stock solutions with a concentration of 100 μM, add a series of BSA with different concentration gradients to the same amount of TPE-diSS solution, and dilute the concentration so that the final concentration of TPE-diSS is 5 μM, and the concentration of BSA The concentrations were 0.005 μM, 0.01 μM, 0.05 μM, 0.1 μM, 0.5 μM, 1.0 μM, 5.0 μM, 10 μM and 50 μM, respectively. At an excitation wavelength of 350 nm, the fluorescence emission spectrum of the TPE-diSS solution was recorded. Such as image 3 As shown, the fluorescence intensity gradually increases with the increase of BSA concentration, and the maximum emission wavelength shows a slight blue shift, which may be due to the intermolecular interaction force between TPE-diSS and BSA.

[0037] B. Record the emission wavelength intensity at 474nm, and the linear fitting curve, such as Figure 4 ,5 As shown, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com