Phase-change heat storage material, and preparation method and application thereof

A technology of phase change heat storage materials and reinforcement materials, applied in heat exchange materials, heat storage equipment, energy storage, etc., can solve the problems of complex preparation process, low phase change latent heat, low thermal conductivity, etc. Effects of separation, high latent heat of phase change, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides a phase change heat storage material.

[0048] The phase change heat storage material comprises the following components by weight fraction: 94% of sodium acetate trihydrate, 2.7% of borax, 3% of carboxymethyl cellulose, and 0.3% of nano silicon dioxide.

[0049] The preparation method of the phase change heat storage material described in this embodiment includes the following steps:

[0050] First heat and melt sodium acetate trihydrate at 80°C for 20 minutes, add borax and carboxymethyl cellulose for the first mixing at 75°C for 15 minutes, then add nano silicon dioxide and mix for the second time at 80°C for 30 minutes, The phase-change heat storage material was obtained, wherein the first mixing and the second mixing were accompanied by agitation, and the rotation speed of the agitation was 1000 rpm.

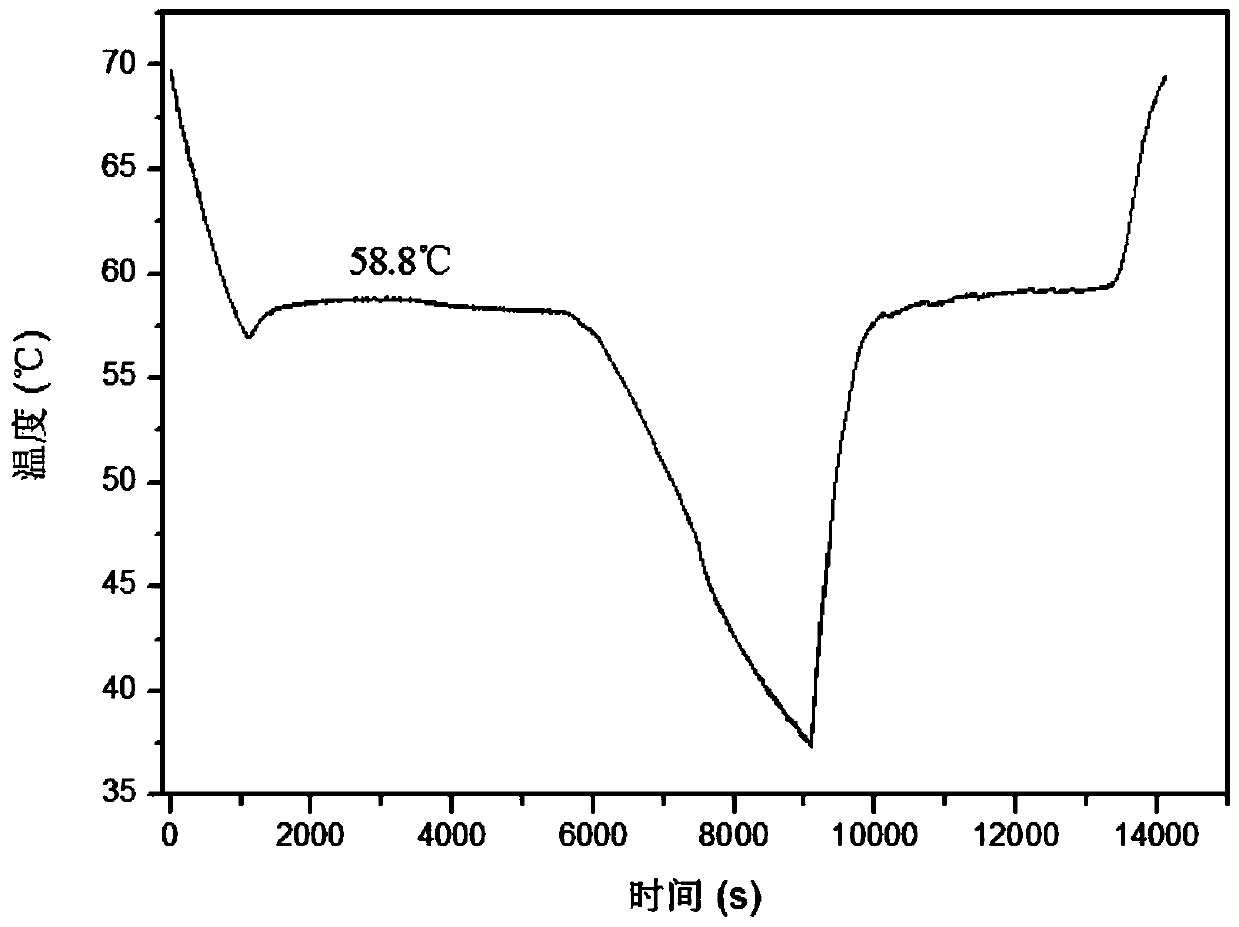

[0051] figure 1 The step cooling curve and heating curve of the phase change heat storage material provided in this example. Wherein, the...

Embodiment 2

[0053] This embodiment provides a phase change heat storage material.

[0054] The phase change heat storage material includes the following components by weight fraction: 97% of sodium acetate trihydrate, 1.2% of disodium hydrogen phosphate dodecahydrate, 1.5% of gelatin, and 0.3% of graphite powder.

[0055] The preparation method of the phase change heat storage material described in this embodiment includes the following steps:

[0056] First heat and melt sodium acetate trihydrate at 75°C for 25 minutes, add disodium hydrogen phosphate dodecahydrate and gelatin for the first mixing at 80°C for 10 minutes, then add graphite powder for the second mixing at 70°C for 40 minutes, The phase change heat storage material was obtained, wherein the first mixing and the second mixing were accompanied by agitation, and the rotation speed of the agitation was 800 rpm.

Embodiment 3

[0058] This embodiment provides a phase change heat storage material.

[0059] The phase-change heat storage material includes the following components by weight fraction: 93.5% of sodium acetate trihydrate, 1% of sodium pyrophosphate decahydrate, 5% of gelatin, and 0.5% of nano-alumina.

[0060] The preparation method of the phase change heat storage material described in this embodiment includes the following steps:

[0061] First heat and melt sodium acetate trihydrate at 80°C for 15 minutes, add sodium pyrophosphate decahydrate and gelatin and mix for the first time at 80°C for 20 minutes, then add nano-alumina and mix for the second time at 75°C for 35 minutes to obtain In the phase change heat storage material, stirring is accompanied during the first mixing and the second mixing, and the stirring speed is 900 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com