Lithium battery anode composite material and preparation method and application thereof

A lithium battery anode and composite material technology, which is applied in the field of lithium battery anode composite materials and its preparation, can solve the problems of electrode cycle performance degradation, material structure damage, volume expansion, etc., and achieve high cycle performance, reversible capacity, and good conductivity , the effect of reducing mechanical stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

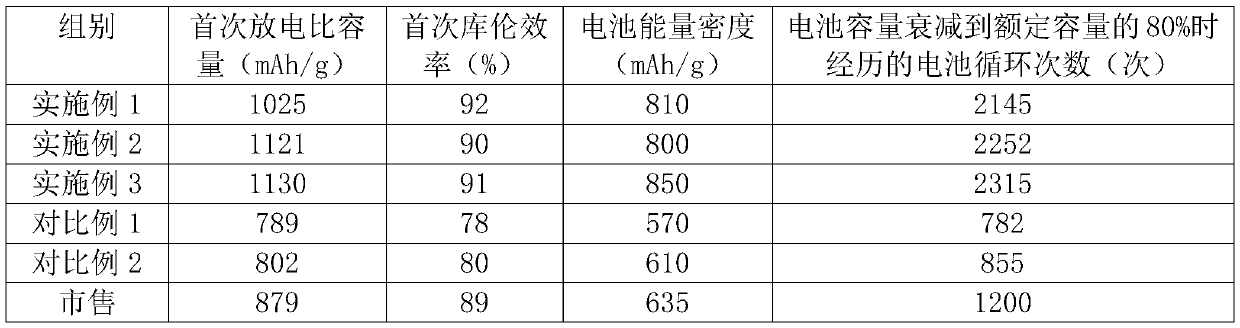

Examples

Embodiment 1

[0030] Embodiment 1 The preparation method of lithium battery anode composite material

[0031] Include the following steps:

[0032] S1. The preparation method of the nano-magnesium-lithium alloy is as follows: after the magnesium-lithium alloy is ground by a planetary ball mill, the grinding speed is 550r / min, the grinding time is 10h, washed with deionized water, and dried to obtain the nano-magnesium-lithium alloy;

[0033] S2. Add 3g of copper nitrate, 1g of lanthanum nitrate, and 3g of aluminum nitrate into 50mL of ethylene glycol, stir and mix evenly, add dropwise 3mol / L NaOH solution to adjust the pH value to 9, continue stirring for 30min, then transfer to the polytetrafluoroethylene liner In the stainless steel hydrothermal reaction kettle, seal it and put it in an oven at 150°C for 12 hours, cool it, discard the supernatant, wash the solid product with deionized water, and dry it to obtain lanthanum aluminate copper;

Embodiment 2

[0035] Embodiment 2 The preparation method of lithium battery anode composite material

[0036] Include the following steps:

[0037] S1. The preparation method of the nano-magnesium-lithium alloy is as follows: after the magnesium-lithium alloy is ground by a planetary ball mill, the grinding speed is 1000r / min, the grinding time is 15h, washed with deionized water, and dried to obtain the nano-magnesium-lithium alloy;

[0038] S2. Add 3g of copper nitrate, 1g of lanthanum nitrate, and 5g of aluminum nitrate into 50mL of ethylene glycol, stir and mix evenly, add dropwise 5mol / L NaOH solution to adjust the pH value to 10, continue stirring for 60min, and then transfer to the polytetrafluoroethylene liner In the stainless steel hydrothermal reaction kettle, seal it and place it in an oven at 170°C for 24 hours, cool it, discard the supernatant, wash the solid product with deionized water, and dry it to obtain lanthanum aluminate copper;

[0039]S3. Grind 50g of graphite to les...

Embodiment 3

[0040] Embodiment 3 The preparation method of lithium battery anode composite material

[0041] Include the following steps:

[0042] S1. The preparation method of the nano-magnesium-lithium alloy is as follows: after the magnesium-lithium alloy is ground by a planetary ball mill, the grinding speed is 700r / min, the grinding time is 12h, washed with deionized water, and dried to obtain the nano-magnesium-lithium alloy;

[0043] S2. Add 6g of copper nitrate, 2g of lanthanum nitrate, and 8g of aluminum nitrate into 100mL of ethylene glycol, stir and mix evenly, add dropwise 4mol / L NaOH solution to adjust the pH value to 8.5, continue stirring for 45min, then transfer to the polytetrafluoroethylene liner In the stainless steel hydrothermal reaction kettle, seal it and put it in an oven at 160 ° C for 18 hours, cool it, discard the supernatant, wash the solid product with deionized water, and dry it to obtain lanthanum copper aluminate;

[0044] S3. Grind 50g of graphite to less ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com