Copper/ceramic bonded body, insulating circuit board, copper/ceramic bonded body production method, and insulating circuit board production method

A technology for circuit substrates and ceramic substrates, used in circuits, manufacturing tools, printed circuits, etc., can solve problems such as insufficient bonding, uneven melting conditions, and residues, and achieve the effect of suppressing excessive reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

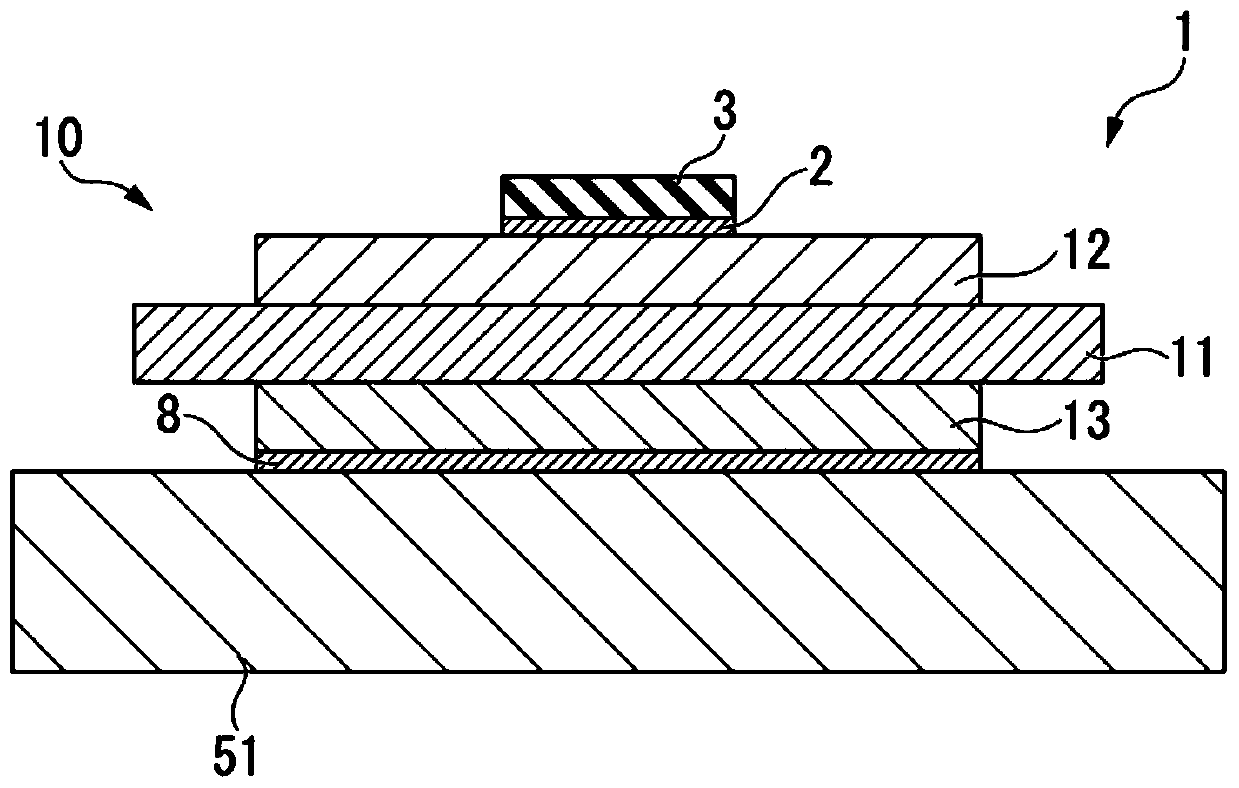

[0066] Below, refer to Figure 1 to Figure 4 , the first embodiment of the present invention will be described.

[0067] The copper-ceramic bonded body according to this embodiment is an insulated circuit board 10 constituted by bonding ceramic substrate 11 as a ceramic member and copper plate 22 (circuit layer 12 ) and copper plate 23 (metal layer 13 ) as copper members.

[0068] figure 1 In FIG. 2 , an insulating circuit board 10 according to the first embodiment of the present invention and a power module 1 using the insulating circuit board 10 are shown.

[0069] The power module 1 includes an insulating circuit substrate 10, and is bonded to one side of the insulating circuit substrate 10 via a first solder layer 2 ( figure 1 The semiconductor element 3 on the upper side) surface and the other side ( figure 1 The lower side of the middle) heat sink 51.

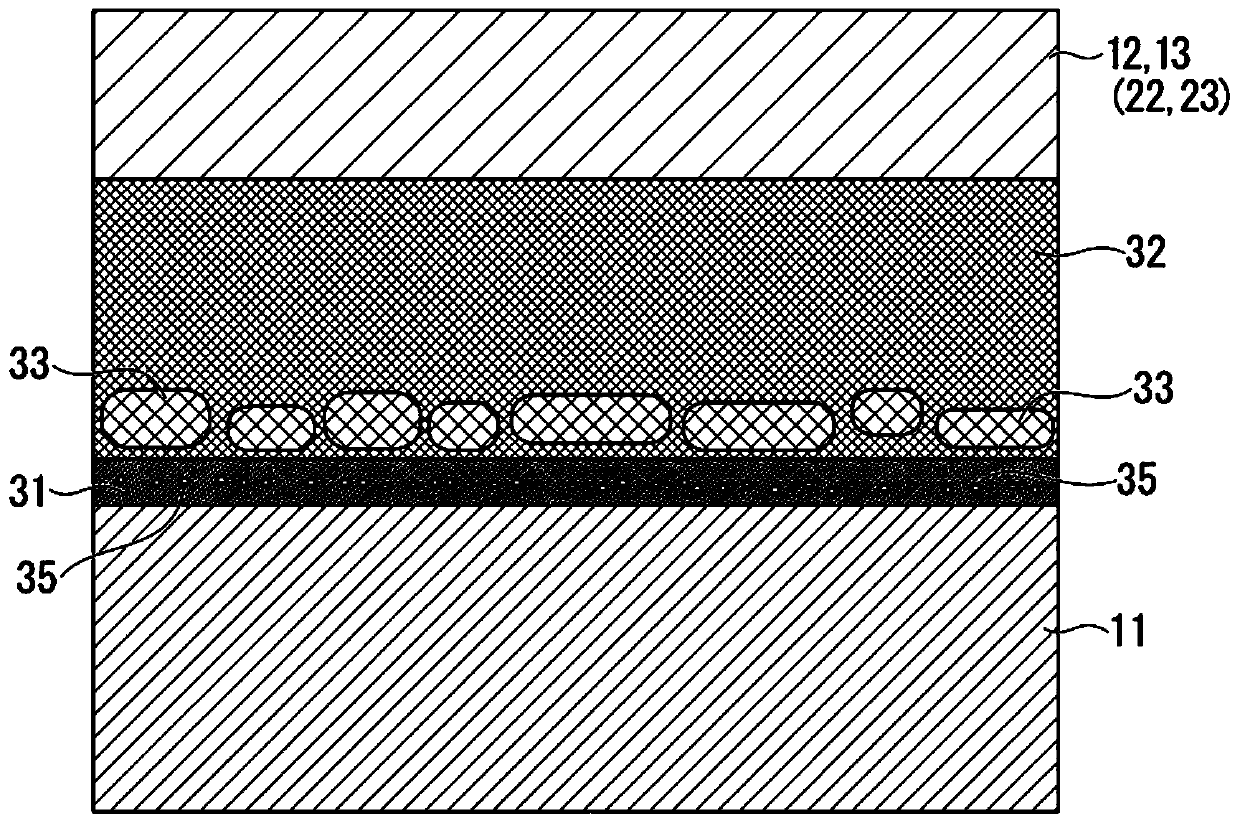

[0070] The insulating circuit substrate 10 includes a ceramic substrate 11, and is arranged on one surface of the c...

no. 2 approach

[0110] Next, refer to Figure 5 to Figure 8 , the second embodiment of the present invention will be described.

[0111] The copper-ceramic bonded body according to the present embodiment is an insulating circuit board 110 constituted by joining a ceramic substrate 111 as a ceramic member and a copper plate 122 (circuit layer 112 ) as a copper member.

[0112] Figure 5 2 shows an insulating circuit substrate 110 and a power module 101 using the insulating circuit substrate 110 as a second embodiment of the present invention.

[0113] The power module 101 includes an insulating circuit substrate 110, and is bonded to one side of the insulating circuit substrate 110 via a solder layer 2 ( Figure 5 The semiconductor element 3 on the upper side) and the other side of the insulating circuit substrate 110 ( Figure 5 The lower side of the middle) heat sink 151.

[0114] The solder layer 2 is made of, for example, a Sn-Ag-based, Sn-In-based or Sn-Ag-Cu-based solder material.

...

Embodiment

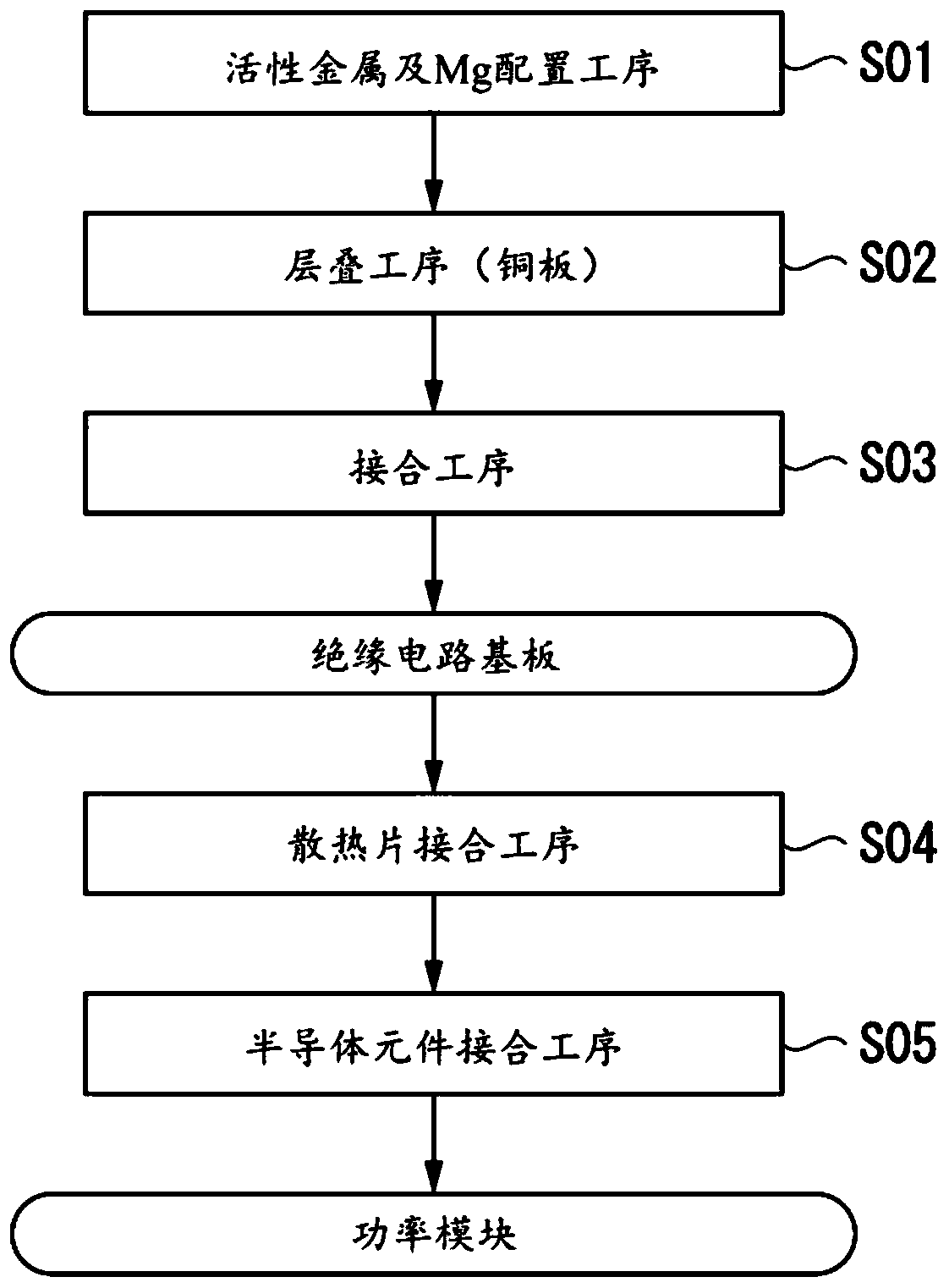

[0169] Confirmation experiments performed to confirm the effectiveness of the present invention will be described.

[0170]

[0171] A copper-ceramic bonded body having the structure shown in Table 1 was formed. Specifically, as shown in Table 1, copper plates on which a simple substance of active metal and a simple substance of Mg were deposited were laminated on both sides of a 40 mm square ceramic substrate made of aluminum oxide, and joined under the joining conditions shown in Table 1. A copper-ceramic bonded body is formed. The thickness of the ceramic substrate was set to 0.635 mm. In addition, the vacuum degree of the vacuum furnace at the time of bonding was set to 5×10 -3 Pa.

[0172] With regard to the copper-ceramic bonded body thus obtained, the presence or absence of Cu particles in the magnesium oxide layer, the Mg solid solution layer, the intermetallic compound phase, and the magnesium oxide layer, and the Cu concentration were confirmed by observing the bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com