Combined biological treatment method for high-concentration COD chromium-containing electroplating cleaning wastewater

A technology for cleaning wastewater and biological treatment, applied in metallurgical wastewater treatment, water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of high refractory components, poor technical and economic indicators, high investment and operating costs, and achieve The effect of solving low efficiency, overcoming poor tolerance to hexavalent chromium toxicity, and improving biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

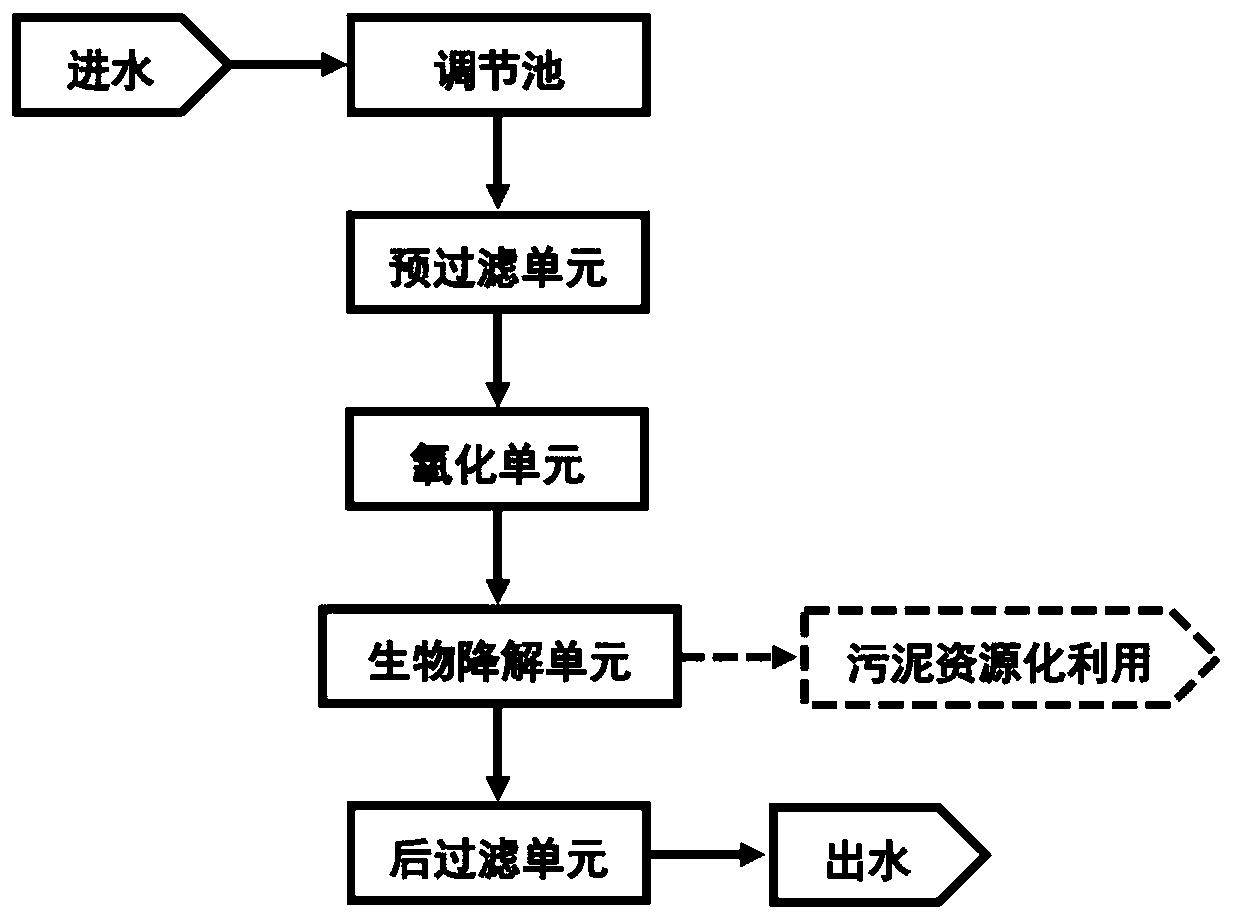

[0026] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0027] like figure 1 Shown, the combined biological treatment method of a kind of high-concentration COD chromium-containing electroplating cleaning wastewater of the present invention, the COD concentration in the electroplating cleaning wastewater ≥ 2000mg / L, hexavalent chromium concentration ≤ 10mg / L; The processing method includes as follows step:

[0028] (1) The waste water is first sent into the regulating tank for homogenization and equalization;

[0029] (2) The effluent from the regulating tank is sent to the primary filter unit to remove large particles of insoluble impurities in the wastewater;

[0030] (3) The effluent from the primary filter unit is sent to the oxidation unit; the oxidation unit adopts heterogeneous catalytic oxidation, under normal temperature and pressure and under the action of a catalyst, the complex organic po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com