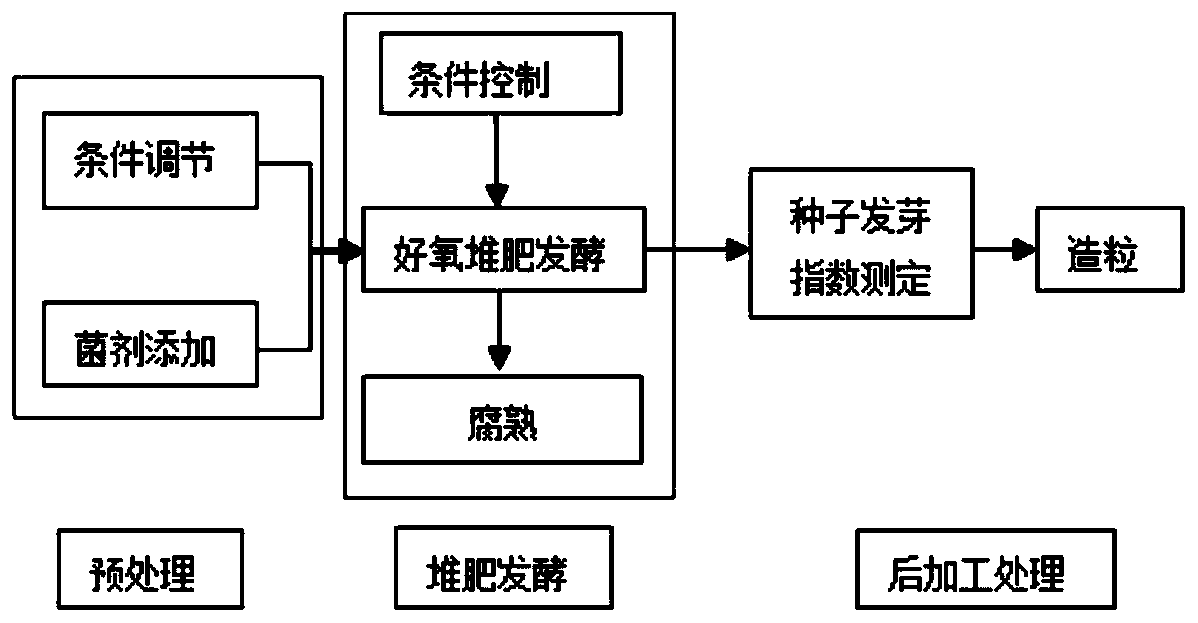

Production process for fermenting organic fertilizer by using Maotai-flavor liquor vinasse

A technology of organic fertilizer and distiller's grains, applied in the direction of organic fertilizer, bio-organic part treatment, application, etc., can solve the problems of reducing application scenarios of organic fertilizer, low C/N value, long cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The preparation of embodiment 1 fermentation bacterial agent

[0058] (1) The deposit number of the Candida arugula is CGMCC No.7902;

[0059] The preparation method of the Candida rugosa inoculum is to add Candida rugosa into a liquid medium, cultivate it at 28-30°C for 2-4 days, and adjust the cell concentration of the obtained liquid seed solution to 10 10 After the cfu / mL, transfer to the bran sterilized at 121 DEG C for 30 minutes, the inoculum amount is 10% (percentage by weight), and then culture at 28-30 DEG C for 8-9 days to obtain a solid microbial agent of a single strain.

[0060] The liquid medium is YPD medium, its components are yeast extract 5g, glucose 20g, peptone 10g, pH natural preparation, 118°C, 20min.

[0061] (2) The preservation number of the Bacillus licheniformis is CGMCC No.7901;

[0062] The preparation method of the Bacillus licheniformis inoculum is to add the Bacillus licheniformis into the liquid medium, cultivate it at 35-37° C. for 1...

Embodiment 2

[0071] The production method of embodiment 2 Maotai-flavor liquor distiller's grains organic fertilizer

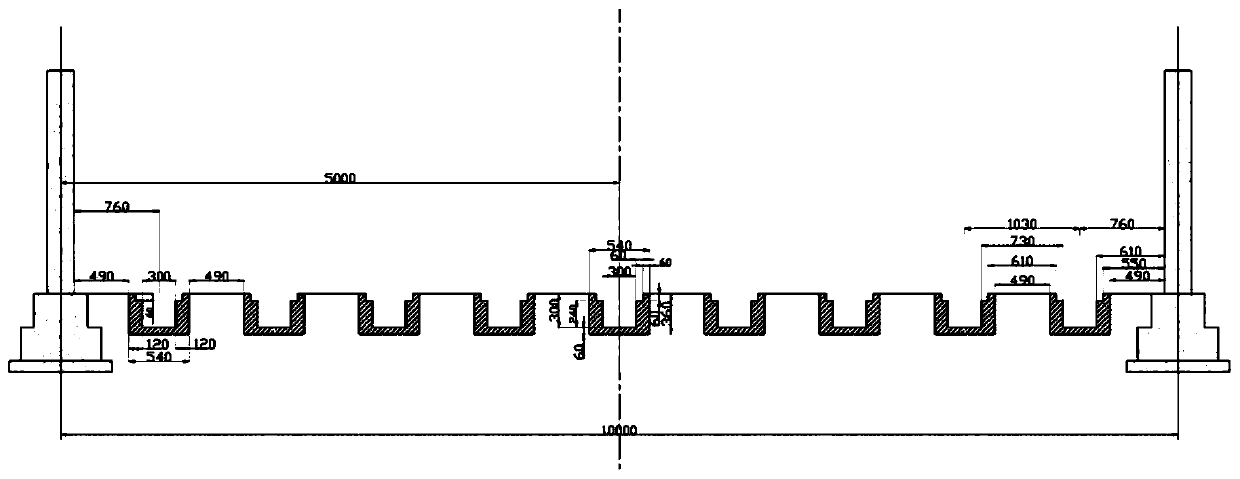

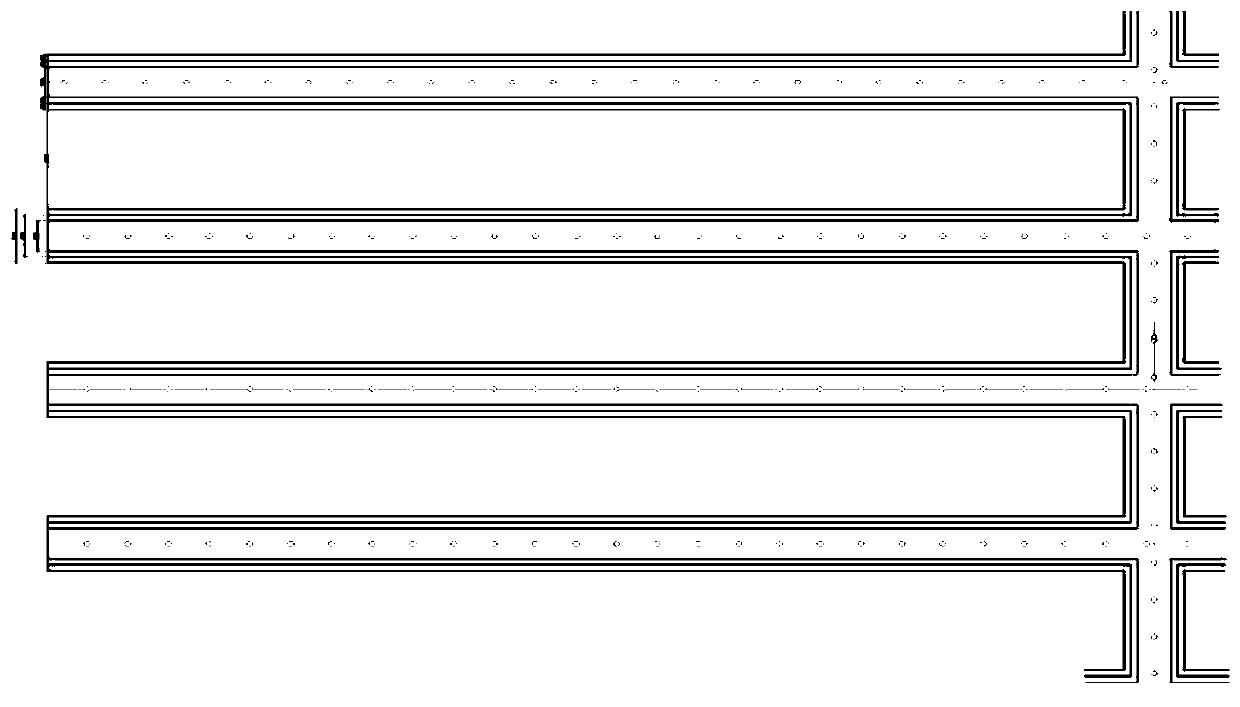

[0072] 1. The Maotai-flavored liquor distiller's grains organic fertilizer fermentation bacterial agent prepared in Example 1 of the present invention, the Maotai-flavored liquor distiller's grains (fresh distiller's grains initial moisture 62%, pH value 3.5) and auxiliary materials (discarded straw from distiller's yeast production) according to the mass ratio The ratio of 0.2:94.8:5 is used for proportioning and mixing, composting is carried out in the fermentation tank method of continuous feeding, and ventilation and fermentation are carried out by jet oxygen supply technology when necessary (see figure 2 and image 3 ), the pile height is 1.5m.

[0073] 2. The first fermentation: Since the compost temperature starts to rise, it is controlled at 15-45°C in the middle temperature stage and 45-65°C in the high-temperature stage, and the temperature above 55°C lasts for...

Embodiment 3

[0078] The production method of embodiment 3 Maotai-flavor liquor distiller's grains organic fertilizer

[0079] 1. The Maotai-flavored liquor distiller's grains organic fertilizer fermentation bacterial agent prepared in Example 1 of the present invention, the Maotai-flavored liquor distiller's grains (fresh distiller's grains initial moisture 65%, pH value 4.5) and auxiliary materials (decomposed dry compost) according to the mass ratio The ratio of 0.5:94.5:5 is used for proportioning and mixing, composting is carried out in the fermentation tank method of continuous feeding, and ventilation and fermentation are carried out through jet oxygen supply technology when necessary (see figure 2 and image 3 ), the pile height is 1.8m.

[0080] 2. The first fermentation: Since the compost temperature starts to rise, it is controlled at 15-45°C in the medium temperature stage and 45-65°C in the high-temperature stage, and the temperature above 55°C lasts for 7 days, reaching the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com