Soluble micro-needle and preparation method thereof

A soluble and microneedle technology, applied in the field of nano-microneedles, can solve the problems of expensive equipment, inability to meet mass production, and large skin damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] This application also provides a method for preparing soluble microneedles, including the following steps:

[0044] Mixing the soluble polymer material and the soluble active material to obtain a mixed solution;

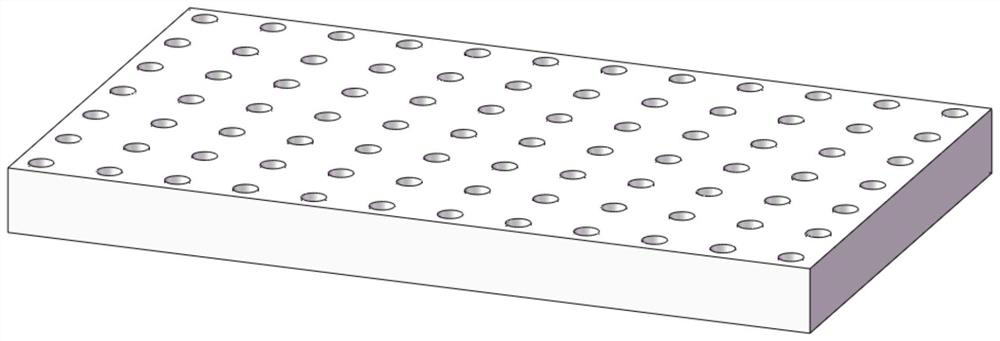

[0045] Add the mixed solution to the female microneedle mold, then vacuum defoam, then solidify and demold to obtain soluble microneedles;

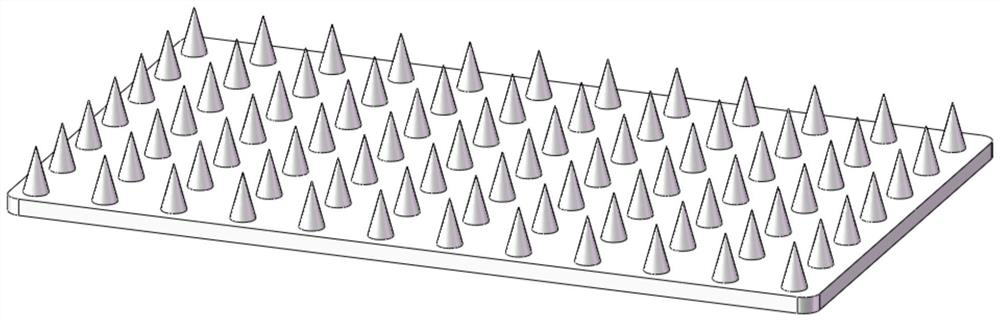

[0046] The microneedle female mold is a microporous polydimethylsiloxane mold obtained from a microneedle male mold inverted mold, and the microneedle male mold is a series of microneedles arranged in any shape prepared by laser direct writing technology .

[0047] In the process of preparing soluble microneedles, this application first prepares the microneedle male mold, which is prepared by laser direct writing technology, specifically:

[0048] Construct a model of the microneedle to be printed, and import the model into the lithography machine in a format that can be recognized by the lithography machine;

[0049] The printing ...

Embodiment 1

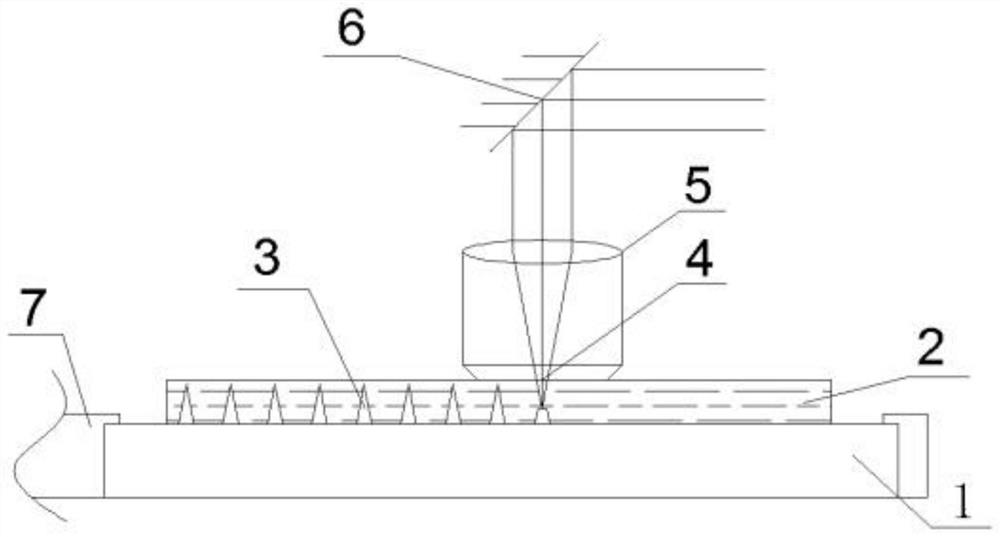

[0061] Example 1 Laser direct writing technology to prepare a microneedle male mold, specifically as follows figure 1 As shown, figure 1 In order to use laser direct writing technology to prepare a schematic diagram of the microneedle male mold, figure 1 1 is a glass slide, 2 is a photoresist, 3 is a nano microneedle, 4 is a focused laser, 5 is a lens, 6 is a galvanometer, and 7 is a printing platform. The specific steps are as follows:

[0062] 1) Construct a three-dimensional model of the outer contour of the microneedle to be printed, export the three-dimensional model into a format recognized by the control software of the three-dimensional lithography machine and import it into the lithography machine. The three-dimensional model includes a cone, a triangular pyramid, a polygonal pyramid, etc. ;

[0063] 2) Take a clean 76mm*26mm*1mm thick glass slide as the printing substrate slide 1, use compressed nitrogen to blow clean, immerse the slide 1 in the acetone solution and ultras...

Embodiment 2

[0067] Example 2 Preparation of soluble microneedles

[0068] 1) Preparation of microneedle preparation solution

[0069] Dissolve 0.5 g of vinylpyrrolidone in 2.5 g of deionized water, stir quickly, weigh 0.3 g of hyaluronic acid (molecular weight 7000), add in three times, stir until fully dissolved, weigh out 0.05 g of coenzyme Q10, stir evenly, and leave it overnight. Centrifuge to remove excess air bubbles and obtain microneedle preparation solution;

[0070] 2) Pour the microneedle production solution into the microneedle female mold prepared in Example 1, and then place the microneedle female mold in a vacuum drying oven at a temperature of 35°C, a vacuum of -0.1Mpa, and a vacuum for 30 minutes. After molding, place the microneedle female mold in a desiccator for 24 hours to fully dry;

[0071] 3) Preparation of microneedle bottom plate

[0072] Dissolve 0.3 g of copovidone, 0.3 g of polyvinyl alcohol, and 0.6 g of hydroxypropyl cellulose in 10 g of deionized water, stir to ful...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com