Manufacturing process of transformer oil with high heat-conducting property

A technology of transformer oil and heat conduction performance, which is applied in the field of transformer oil and can solve problems such as heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

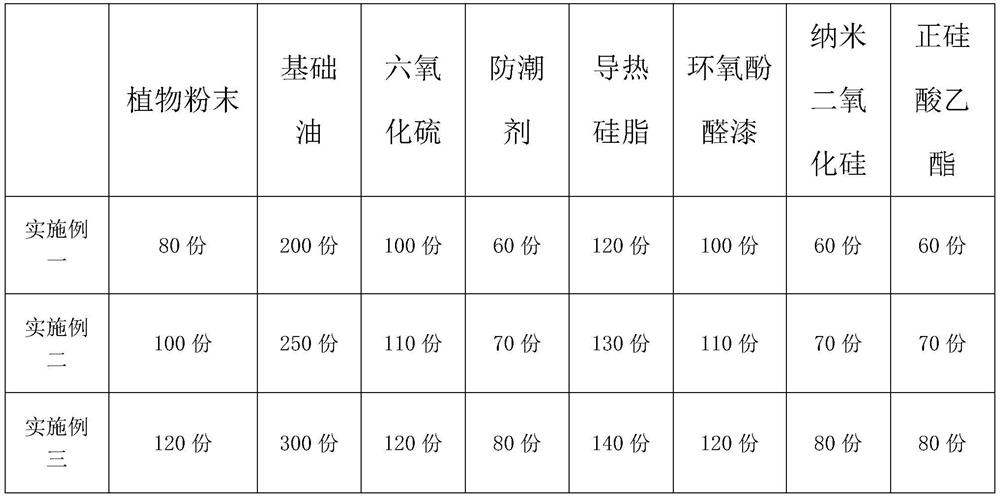

[0026] Embodiment 1: A manufacturing process of transformer oil with strong thermal conductivity, comprising the following raw materials in parts by weight: 80 parts of plant powder, 200 parts of base oil, 100 parts of sulfur hexoxide , 60 parts of moisture-proof agent, 120 parts of heat-conducting silicone grease, 100 parts of epoxy phenolic paint, 60 parts of nano-silicon dioxide, 60 parts of tetraethyl orthosilicate, and the plant powder is natural plants of gallnut, sumac wood and salt skin wood, including the following Raw materials in parts by weight ratio: the ratio of nano silicon dioxide and ethyl orthosilicate is 1:1, comprising the following steps:

[0027] Step 1: plant extraction, grind the natural plants of Chinese Gallnut, Cotinus chinensis and Salmonella, and extract the plant powder; Step 2: Collect, collect the base oil, and use it for later use after impurity removal; Step 3: Mix, mix the plants Powder, sulfur hexoxide, moisture-proof agent, heat-conducting ...

Embodiment 2

[0029] Embodiment two: a kind of transformer oil production process with strong thermal conductivity, comprising the following raw materials in parts by weight ratio: comprising the raw materials in the following parts by weight ratio: 100 parts of plant powder, 250 parts of base oil, 110 parts of sulfur hexoxide , 70 parts of moisture-proof agent, 130 parts of heat-conducting silicone grease, 110 parts of epoxy phenolic varnish, 70 parts of nano-silicon dioxide, 70 parts of tetraethyl orthosilicate, and the plant powders are natural plants of gallnut, sumac wood and salt skin wood, including the following Raw materials in parts by weight ratio: the ratio of nano silicon dioxide and ethyl orthosilicate is 1:1, comprising the following steps:

[0030] Step 1: plant extraction, grind the natural plants of Chinese Gallnut, Cotinus chinensis and Salmonella, and extract the plant powder; Step 2: Collect, collect the base oil, and use it for later use after impurity removal; Step 3: ...

Embodiment 3

[0032] Embodiment three: a kind of transformer oil production process with strong thermal conductivity, comprising the following raw materials in parts by weight: comprising the raw materials in the following parts by weight: 120 parts of plant powder, 300 parts of base oil, 120 parts of sulfur hexoxide , 80 parts of moisture-proof agent, 140 parts of heat-conducting silicone grease, 120 parts of epoxy phenolic varnish, 80 parts of nano-silicon dioxide, 80 parts of tetraethyl orthosilicate, and the plant powders are natural plants of gallnut, sumac wood and salt skin wood, including the following Raw materials in parts by weight ratio: the ratio of nano silicon dioxide and ethyl orthosilicate is 1:1, comprising the following steps:

[0033] Step 1: plant extraction, grind the natural plants of Chinese Gallnut, Cotinus chinensis and Salmonella, and extract the plant powder; Step 2: Collect, collect the base oil, and use it for later use after impurity removal; Step 3: Mix, mix t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com