Organic/inorganic composite electrolyte membrane for solid-state sodium ion battery, preparation and application thereof

A composite electrolyte membrane and inorganic composite technology, which is applied in the field of electrolyte preparation, can solve problems such as air and water instability, poor interface compatibility, and poor ionic conductivity, and achieve excellent mechanical properties, high ionic conductivity, and high ion conductivity. The effect of migration number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0040] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

[0041] Na used in the following examples 3 Zr 2 Si 2 PO 12 The preparation method of inorganic ceramic powder refers to following documents:

[0042] Narayanan S, Reid S, Butler S, et al. Sintering temperature, excess sodium, and phosphorous de...

Embodiment 1

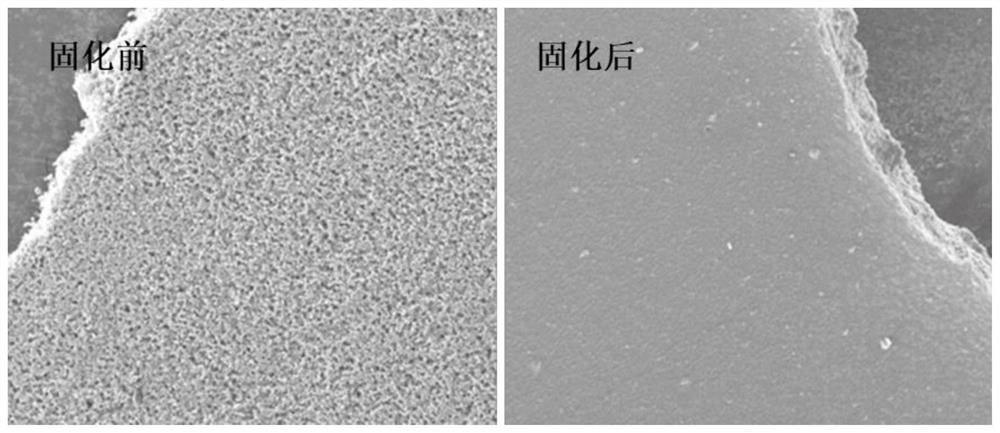

[0045] Synthesis of NZSP(Na 3 Zr 2 Si 2 PO 12 ) Inorganic ceramic powder, the NZSP ceramic powder prepared by 100mg is mixed with 300mg PVDF-HFP, fully dispersed in 3ml of acetone and methylacetamide mixed solution with a volume ratio of 2:1, fully stirred to obtain a mixed slurry, The mixed slurry was evenly scraped on a glass plate, then soaked in water to form a film, and dried to prepare a flexible porous base film with a thickness of 20 μm. The flexible porous base membrane has a porous ceramic skeleton structure with a pore diameter of about 1 μm, which is recorded as a composite electrolyte membrane before curing.

[0046] Dissolve 40mg of polyethylene oxide (PEO) in 2g of dimethylsulfoxide (DMSO), and add 40mg of 2-hydroxy-2-methylpropane to 1ml of ethoxylated trimethylolpropane triacrylate Propiophenone was used as photoinitiator and mixed well. Take 1ml of the above-mentioned PEO solution and add it to the above-mentioned polymer monomer solution and stir evenly...

Embodiment 2

[0053] Other conditions are the same as in Example 1, except that 100 mg of dibenzoyl peroxide is added to 1 ml of ethoxylated trimethylolpropane triacrylate and mixed uniformly. Take 1ml of PEO solution and add it to the above polymer monomer solution and stir evenly, finally add 150mg sodium hexafluorophosphate, stir evenly and set aside. A circular flexible porous membrane with a diameter of 16 mm was soaked in the above-prepared monomer solution for 12 hours, taken out and placed in an oven for curing for 30 minutes to obtain the target electrolyte membrane.

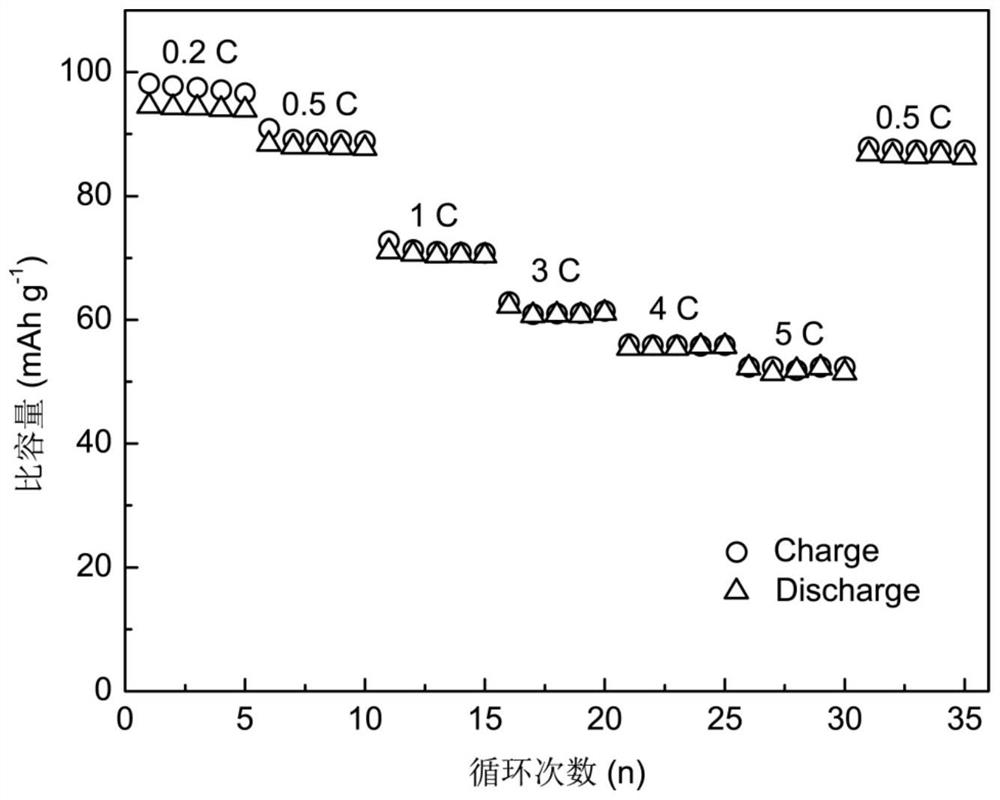

[0054] The electrochemical performance test results show that the thickness of the composite electrolyte membrane prepared in Example 2 is 40 μm, the ion mobility coefficient at 60°C is 0.603, and the ion conductivity is 3.20*10 -4 S / cm, using sodium vanadium phosphate as the positive electrode to assemble a sodium-ion half-cell, the discharge capacity is 92mA h / g at a rate of 0.2C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com