Microporous composite biological ceramic bone repair scaffold as well as preparation method and device thereof

A technology for composite bioceramics and bone repair, applied in medical science, prosthesis, additive processing, etc., can solve the problems of large differences in natural bone, reduce wear, improve differentiation and osteogenesis efficiency, and improve spatial structure and biological performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

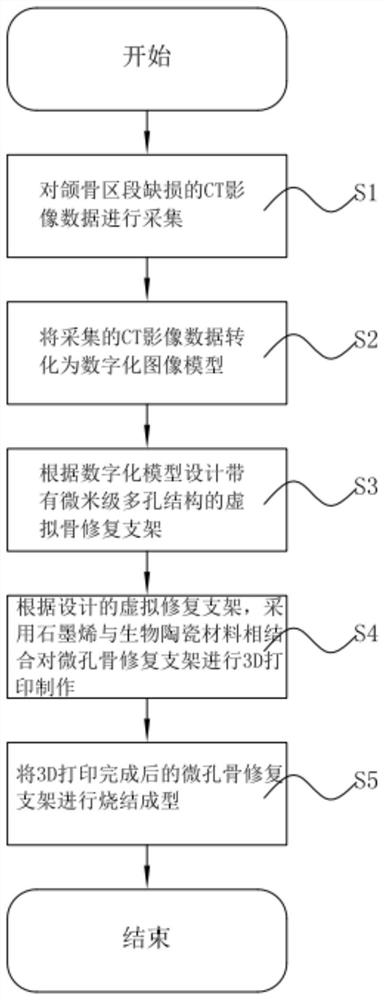

[0063] Such as figure 1 Shown, this preparation method comprises:

[0064] S1: Collect CT image data of jaw segmental defects; the data can be spiral CT or CBCT imaging data, and the scanning slice thickness is 0.2-0.625mm, which is convenient for obtaining clear CT impact data.

[0065] S2: Transform the collected CT image data into a digital image model; use the currently commonly used commercial image processing software to establish a digital three-dimensional image model of the jaw defect area, and display the shape and thickness of soft and hard tissues in the bone defect area, etc. Through the indicators such as the shape and thickness of soft and hard tissues, it is convenient to carry out data analysis on the digital image model.

[0066] S3: Design a virtual bone repair scaffold with a micron-scale porous structure according to the digital model; at the same time, design a virtual bone repair scaffold with a suitable pore size and porosity according to the precisio...

Embodiment 1

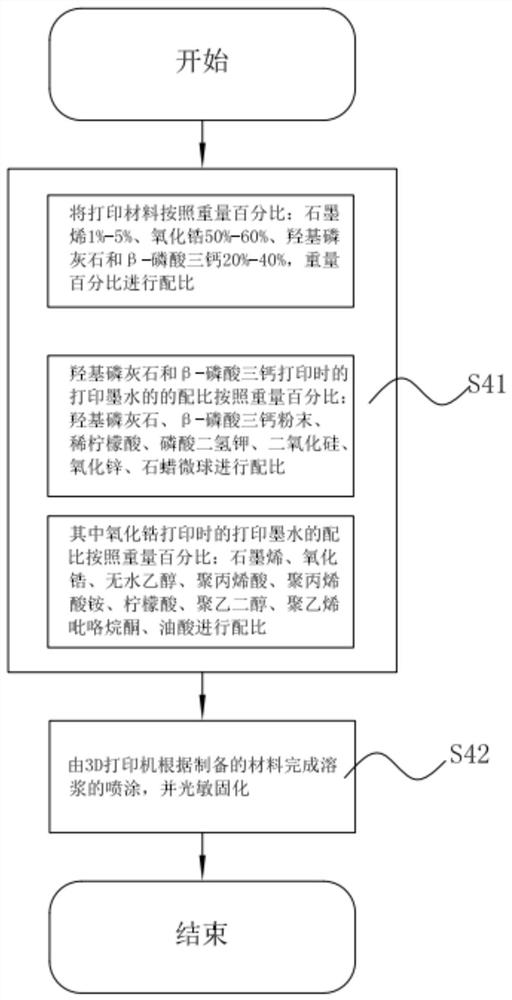

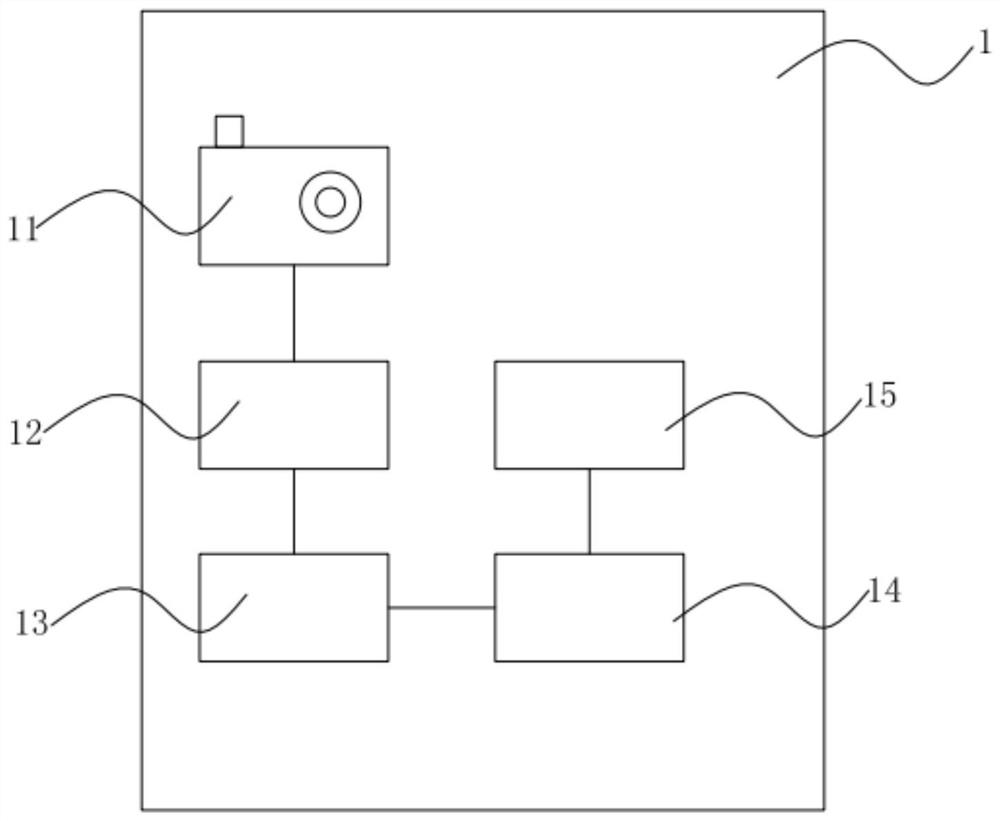

[0089] Digital design of the microporous bone repair bracket: collect the spiral CT or CBCT imaging data of the jaw segmental defect through the data acquisition part 11, and the scanning layer thickness is 0.425mm, and clear imaging data can be obtained, which is convenient for data conversion and image Processing software integration, using data conversion component 12 (commercialized image processing software) to establish a digital three-dimensional image model of the jaw defect area, respectively displaying the shape and thickness of soft and hard tissues in the bone defect area, and aiming at image distortion after digital three-dimensional imaging or noise interference, denoising processing is carried out by means of filtering, and two image quality evaluation standards, signal mean square error (MSE) and peak signal-to-noise ratio (PSNR) are applied, and the reconstructed image after denoising and the original image are evaluated by mean square Error (MSE) and peak sign...

Embodiment 2-3

[0093] As shown in Table 2, the difference from Example 1 is: the weight percentage of each component of the printing material and the printing ink component weight percentage of hydroxyapatite, β-tricalcium phosphate and zirconia are different, and other technical solutions are different from Example 1 is the same.

[0094]

[0095] Table 2: Comparison table of the weight percentages of the components of the 3D printing materials, hydroxyapatite and β-tricalcium phosphate printing inks, and zirconia printing inks of Examples 1-3

[0096] In summary, by adjusting the proportion of graphene and bioceramic materials, the conductivity and high toughness of graphene materials, the high strength and wear resistance of zirconia, and the use of hydroxyapatite and β-phosphate The good osteoinductive activity of tricalcium makes the physical properties of the new material, such as compressive strength, elastic modulus, fracture toughness and other indicators, closer to natural bone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com