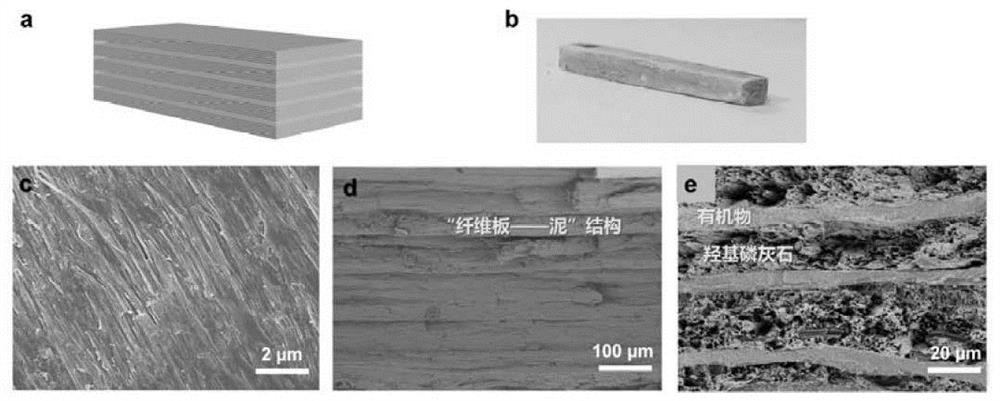

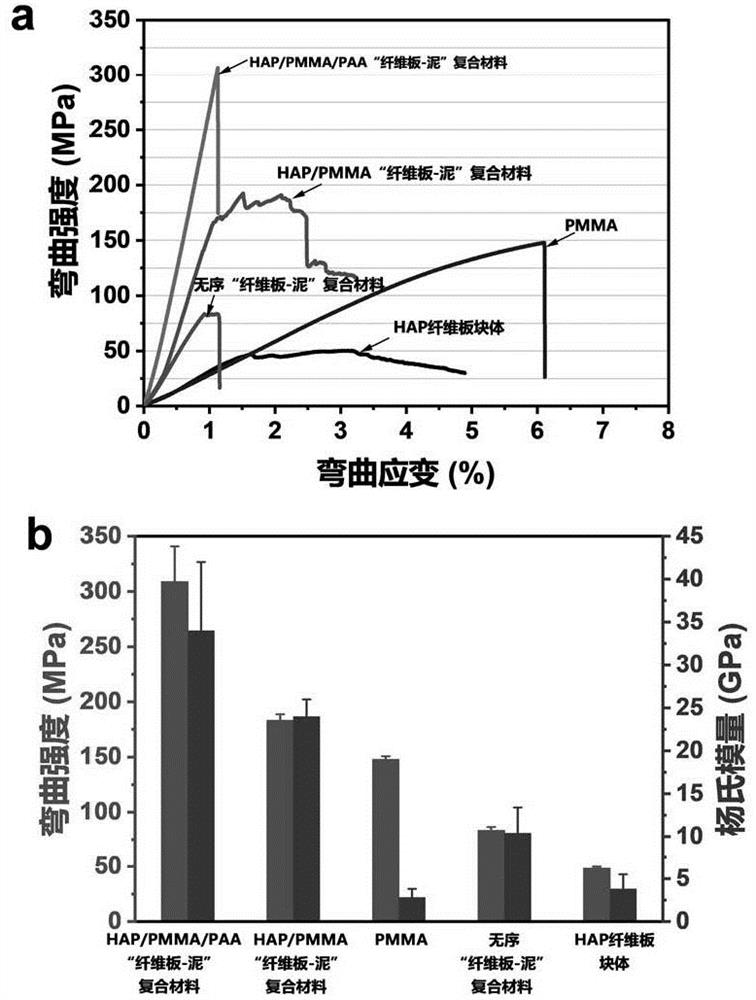

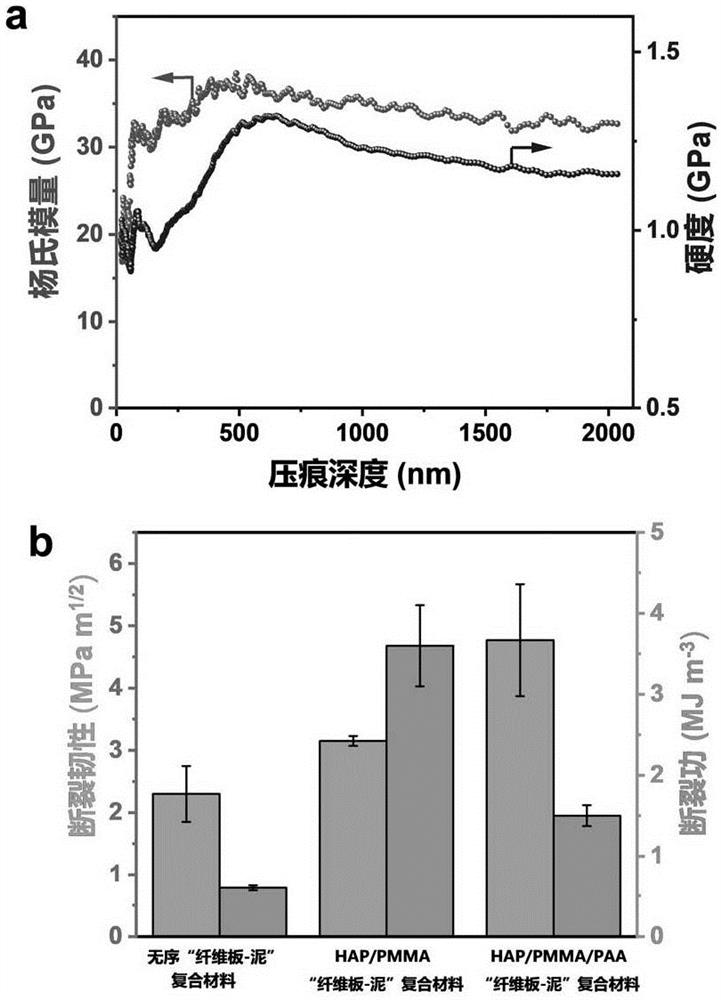

Three-dimensional multistage highly-ordered hydroxyapatite super-long nanowire fiberboard-mud structure composite material, preparation method and application thereof

A hydroxyapatite, highly ordered technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of low material strength, inability to meet tolerance and mechanical properties, and structural advantages No obvious problems, etc., to achieve the effect of excellent mechanical properties and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Under mechanical stirring, mix 135mL deionized water, 105mL oleic acid and 60mL methanol evenly, then slowly add 150mL aqueous solution containing 10.5g sodium hydroxide, then slowly add 120mL aqueous solution containing 3.33g calcium chloride, and finally slowly add 180mL containing 9. 360g aqueous solution of sodium dihydrogen phosphate dihydrate; after stirring evenly, pour the solution into the reaction kettle, seal it, heat it to 180°C, and keep it warm for 26h. The solvothermal product consisted of a white milk at the bottom and a pale yellow supernatant, and by mixing the white milk and supernatant at a volume ratio of 4:1, a hydroxyapatite ultralong nanowire slurry was obtained and heated at 60 °C Keep warm for 30min. Take 6 mL of hydroxyapatite ultralong nanowire slurry and inject it into ethanol at room temperature through a syringe with a needle diameter of about 1100 μm (injection procedure: moving distance 2 cm and flow rate 5 mL / min). The macro-scale fibe...

Embodiment 2

[0058] Under mechanical stirring, mix 135mL deionized water, 105mL oleic acid and 60mL methanol evenly, then slowly add 150mL aqueous solution containing 10.5g sodium hydroxide, then slowly add 120mL aqueous solution containing 3.33g calcium chloride, and finally slowly add 180mL containing 9. 360g aqueous solution of sodium dihydrogen phosphate dihydrate; after stirring evenly, pour the solution into the reaction kettle, seal it, heat it to 180°C, and keep it warm for 26h. The solvothermal product consisted of a white milk at the bottom and a pale yellow supernatant, and by mixing the white milk and supernatant at a volume ratio of 4:1, a hydroxyapatite ultralong nanowire slurry was obtained and heated at 60 °C Keep warm for 30min. The hydroxyapatite ultralong nanowire slurry was injected into ethanol at room temperature through a syringe with a needle diameter of about 1100 μm (injection procedure: moving distance 2 cm and flow rate 4 mL / min). The macro-scale fibers of the ...

Embodiment 3

[0060] Under mechanical stirring, mix 135mL deionized water, 105mL oleic acid and 60mL methanol evenly, then slowly add 150mL aqueous solution containing 10.5g sodium hydroxide, then slowly add 120mL aqueous solution containing 3.33g calcium chloride, and finally slowly add 180mL containing 9. 360g aqueous solution of sodium dihydrogen phosphate dihydrate; after stirring evenly, pour the solution into the reaction kettle, seal it, heat it to 180°C, and keep it warm for 26h. The solvothermal product consisted of a white milk at the bottom and a pale yellow supernatant, and the hydroxyapatite ultralong nanowire slurry was obtained by mixing the white milk and the supernatant at a volume ratio of 4:1, and heated at 60 °C Keep warm for 30min. The hydroxyapatite ultralong nanowire slurry was injected into ethanol at room temperature through a syringe with a needle diameter of about 1100 μm (injection procedure: moving distance 2 cm and flow rate 4 mL / min). The macro-scale fibers o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com