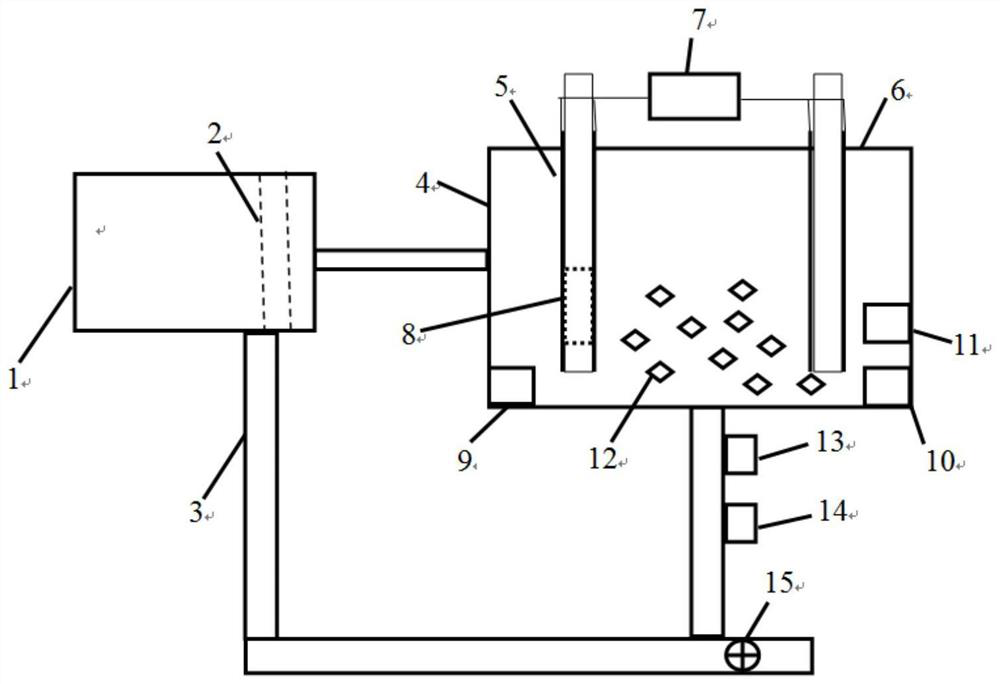

Ultrasonic ozone coupled photoelectrocatalysis water treatment system and water treatment method

A water treatment system, photoelectric catalysis technology, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, special compound water treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Treatment of Zn using the above system 2+ 1L of water with a content of 3000mg / L, wherein the particle filter plate is selected from a quartz sand filter plate, and the temperature of the water in the degradation tank is controlled at 40-60°C; the pH of the water is maintained at about 4; the electrochemical degradation module uses a processing unit , the anode and the cathode are composed of hollow porous cylindrical electrodes that are coaxial in the center but not in contact with each other. The stainless steel is used as the cathode, the boron-doped diamond electrode is used as the anode, the distance between the plates is 10mm, and the energizing voltage is 4V. The ultrasonic emission head is built in the hollow of the anode to provide ultrasonic waves that propagate outward from the porous part of the anode, and the ozone that is controlled to pass through is mainly around the anode, with g-C 3 N 4 The photocatalyst catalyst size is 0.1-1μm; after 120min, Zn 2+...

Embodiment 2

[0073] The anode is a gradient boron-doped electrode, and its preparation method is as follows:

[0074] In this embodiment 1, both electrode A and electrode B are boron-doped diamond electrodes (BDD electrodes), and the preparation method of boron-doped diamond electrodes is:

[0075] 1.1 Substrate material pretreatment

[0076] First, the cylindrical foam Ti is used as the substrate, and it is polished with 600#, 800#, and 1000# metallographic sandpaper; then the polished foam Ti substrate is immersed in acetone (CH 3 COCH 3 ), absolute ethanol (C 2 h 5 OH) in ultrasonic oscillation for 10 min; then the foamed Ti substrate was placed in the nano-diamond suspension and seed crystals were ultrasonically planted for 30 min to enhance nucleation. Finally, rinse with deionized ultrapure water and dry for use.

[0077] 1.2BDD film deposition

[0078] (1) The hot wire used in this paper is The straight tungsten wire is used to completely cover the straight wire directly abo...

Embodiment 3

[0089] Treat Ni with the above system 2+ 1L of water with a content of 2800mg / L, wherein the particle filter plate is selected from microporous Al with a porosity greater than 35PPI 2 o 3 Foam ceramic plate, control the water temperature in the degradation tank to be 50-60°C; the pH of the water is maintained at about 4; the electrochemical degradation module adopts a processing unit, the anode and the cathode are formed by a hollow porous cylinder with the center coaxial but not in contact with each other. The electrodes are composed of stainless steel as the cathode, boron-doped diamond electrodes as the anode, the distance between the plates is 12mm, and the energizing voltage is 6V. The ultrasonic emission head is built in the hollow of the anode to provide ultrasonic waves that propagate outward from the porous part of the anode, and the ozone that is controlled to pass through is mainly formed around the anode as TiO 2 / g -C 3 N 4 The size of the photocatalyst cataly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com