PH-induced reversible color-changing plastic bottle as well as preparation method and application thereof

A technology of color-changing plastics and raw materials, which is applied in the direction of analyzing materials through chemical reactions and observing the effects of chemical indicators on materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

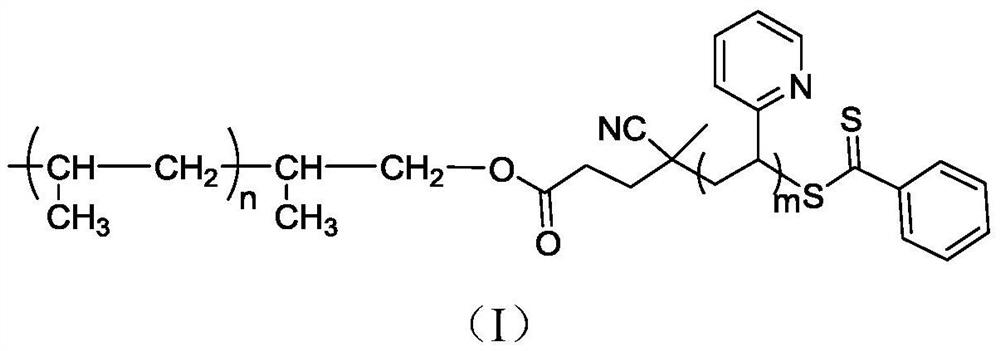

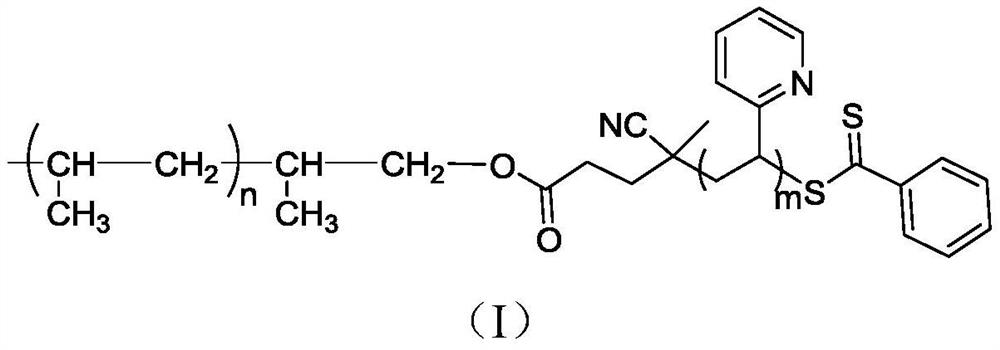

[0033] Synthesis of polypropylene macromolecular transfer agents.

[0034] Add 4-cyano-4-(thiobenzoic acid) pentanoic acid (0.93g, 3.35mmol) and 15ml of anhydrous tetrahydrofuran THF into a 50ml branch bottle equipped with a stirring bar, under room temperature, keep stirring, slowly drop Add thionyl chloride SOCl 2 (1.2ml, 16.75mmol), reflux at 70°C for 1.5h, remove SOCl under reduced pressure after finishing the reaction 2 and THF to obtain a yellow oily product Y, which was dissolved by adding an appropriate amount of anhydrous toluene.

[0035] Add single-end hydroxyl polypropylene PP-OH (2g, 0.67mmol) into a branch bottle equipped with a stirrer, under N 2 Under the atmosphere, use a disposable syringe to inject 40ml of anhydrous toluene, heat to 75°C, stir continuously, add 1ml of pyridine after it is completely dissolved, and after stirring for 15min, slowly add the above-mentioned yellow oily product Y dissolved in toluene solution, at 80°C After stirring for 1.5 h,...

Embodiment 2

[0037] Synthesis of pH-sensitive polypropylene diblock copolymers.

[0038] Polypropylene macromolecule transfer agent (0.16g, 0.05mmol), AIBN (1.64mg, 0.01mmol), 2-vinylpyridine (1.51g, 10.0mmol) and 10ml of toluene / DMF (v / v:9 / 1 ) mixed solvents were added to 25ml Schlenk bottles with stirring bars, and after three cycles of liquid nitrogen freezing-pumping-thawing, the polymerization reaction was carried out in an oil bath with a pre-set temperature of 85°C. After the polymer was dissolved, continue After reacting for 1 hour, the Schlenk bottle was immediately taken out and placed in liquid nitrogen to cool. After two cycles of THF / ether dissolution / precipitation, it was dried in vacuum at 40°C to constant weight to obtain 1.18 g of yellow solid powder with a yield of 71%. , that is, pH-sensitive polypropylene diblock copolymer.

Embodiment 3

[0040] Preparation of pH-induced reversible discoloration plastic bottles.

[0041] According to pH sensitive polypropylene diblock copolymer 82 parts, organotin stabilizer 4.0 parts, polyvinyl alcohol 6.0 parts, antioxidant 1.0 parts, zinc stearate 4.0 parts, flame retardant 2.5 parts, other additives 0.5 parts The weight ratio is to weigh the raw materials, stir and mix each component material with a mixer, and dry mix it in a high-speed mixer for 5 minutes to obtain a mixture a, put the mixture a into a twin-screw extruder to extrude and granulate, and the screw extruder The extrusion processing temperature in the machine is controlled at 180°C, the vacuum negative pressure is above 0.6MPA, the preform is extruded, the thickness of the preform is adjusted to be uniform, and the weight is set according to the product standard. Finally, a pH-induced reversible color plastic bottle is formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com