Efficient cold sizing agent containing polysiloxane acrylate and preparation method of efficient cold sizing agent

A technology of polysiloxane acrylate and cold slurry agent, which is applied in the direction of improved hand-feeling fibers, wear-resistant fibers, textiles and papermaking, etc., and can solve the difficulties of popularization and application, spinning yarn pollution and yellowing, product quality risks, etc. problems, achieve good decoration, reduce warp breakage, and reduce friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

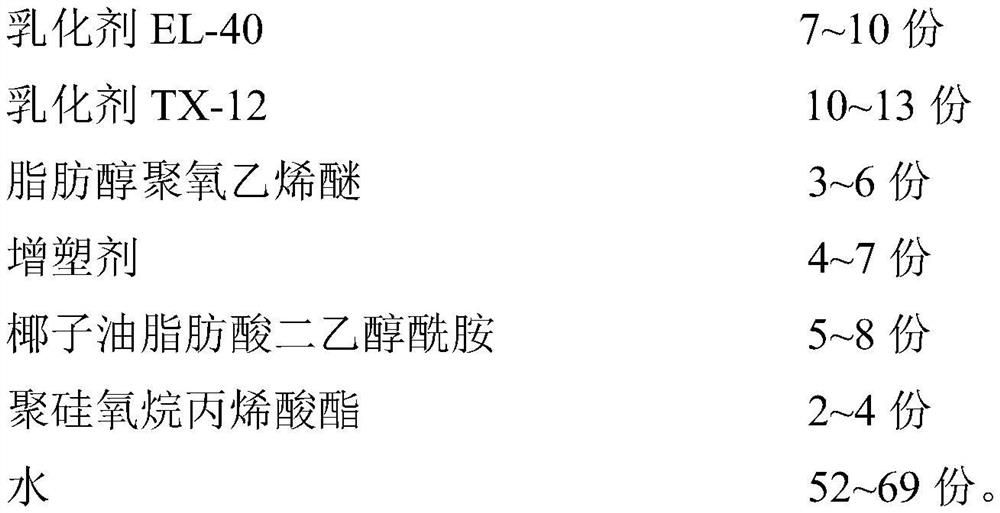

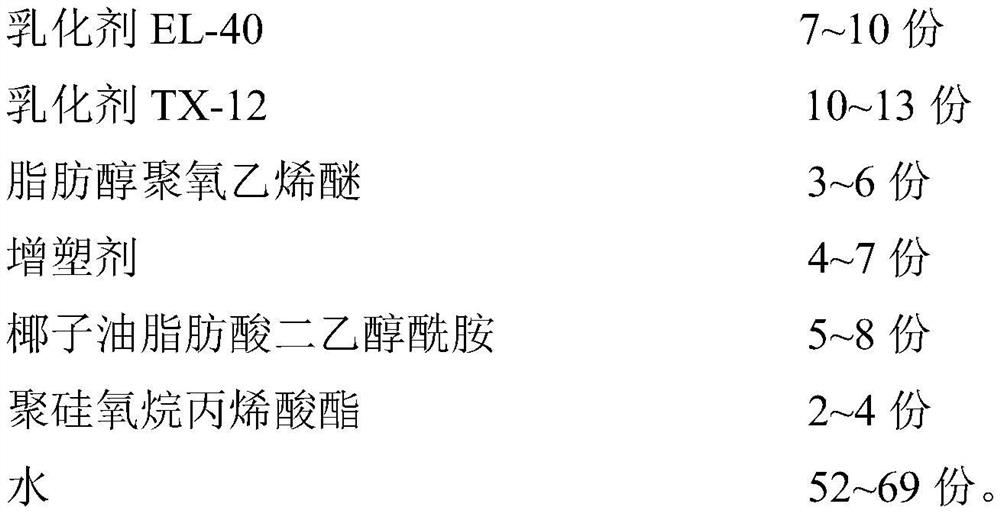

Method used

Image

Examples

Embodiment 1

[0027] Add 69kg of water into the reaction kettle, start stirring and raise the temperature in the reaction kettle to 50°C and keep it warm, then slowly add 2kg of polysiloxane acrylate into the reaction kettle, and keep stirring until completely dispersed, add 7kg of emulsifier EL -40 into the reaction kettle, stirred until completely dissolved, 10kg emulsifier TX-12 was added into the reaction kettle, stirred until completely dissolved, 3kg fatty alcohol polyoxyethylene ether was added into the reaction kettle, stirred until completely dissolved, 4kg polyoxyethylene Add ethylene glycol PEG1500 into the reactor, stir until completely dissolved, add 5kg of coconut oil fatty acid diethanolamide into the reactor, stir until completely dissolved to obtain a high-efficiency cold slurry containing polysiloxane acrylate.

[0028] The cold paste has a colorless and transparent appearance, a viscosity of 135mps·s, and a pH value of 6-7.

Embodiment 2

[0030] Add 52kg of water into the reaction kettle, start stirring and raise the temperature in the reaction kettle to 40°C and keep it warm, then slowly add 4kg of polysiloxane acrylate into the reaction kettle, and keep stirring until completely dispersed, add 10kg of emulsifier EL -40 was added into the reaction kettle, stirred until completely dissolved, 13kg emulsifier TX-12 was added into the reaction kettle, stirred until completely dissolved, 6kg fatty alcohol polyoxyethylene ether was added into the reaction kettle, stirred until completely dissolved, 7kg polyoxyethylene Add ethylene glycol PEG6000 into the reactor, stir until completely dissolved, add 8kg of coconut oil fatty acid diethanolamide into the reactor, stir until completely dissolved to obtain a high-efficiency cold slurry containing polysiloxane acrylate.

[0031] The cold slurry has a colorless and transparent appearance, a viscosity of 170mps·s, and a pH value of 6-7.

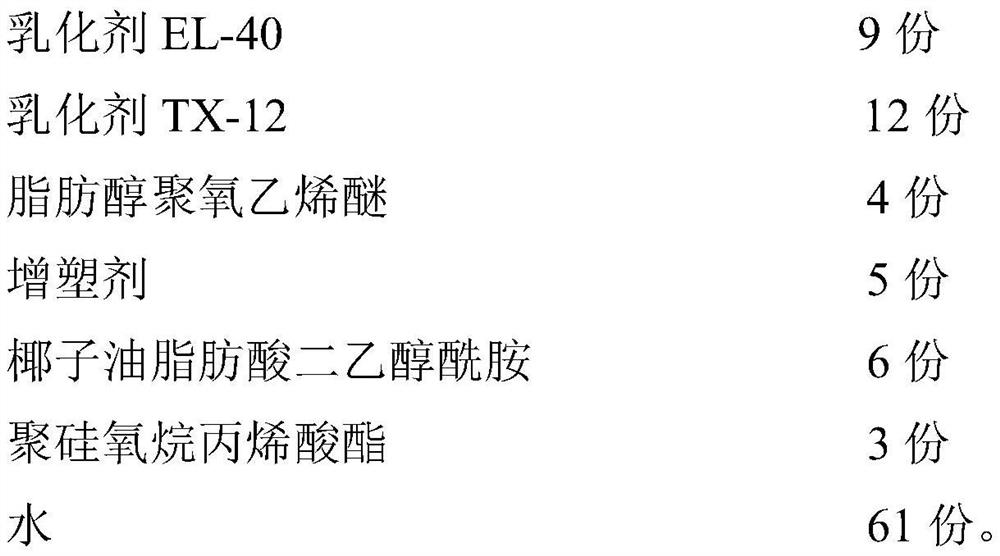

Embodiment 3

[0033] Add 61kg of water into the reaction kettle, start stirring and raise the temperature in the reaction kettle to 50°C and keep it warm, then slowly add 3kg of polysiloxane acrylate into the reaction kettle, and keep stirring until completely dispersed, add 8kg of emulsifier EL -40 was added into the reaction kettle, stirred until completely dissolved, 11kg emulsifier TX-12 was added into the reaction kettle, stirred until completely dissolved, 5kg fatty alcohol polyoxyethylene ether was added into the reaction kettle, stirred until completely dissolved, 6kg Add diol into the reaction kettle, stir until completely dissolved, add 6 kg of coconut oil fatty acid diethanolamide into the reaction kettle, stir until completely dissolved to obtain a high-efficiency cold slurry containing polysiloxane acrylate.

[0034] The cold slurry has a colorless and transparent appearance, a viscosity of 140mps·s, and a pH value of 6-7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com