Magnetic CNx catalyst, preparation method thereof, and application of magnetic CNx catalyst in garbage rotten odor

A catalyst and magnetic technology, applied in the field of magnetic CNx catalyst and its preparation, to achieve the effects of enhancing photocatalytic activity, improving catalytic oxidation performance, and increasing relaxation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

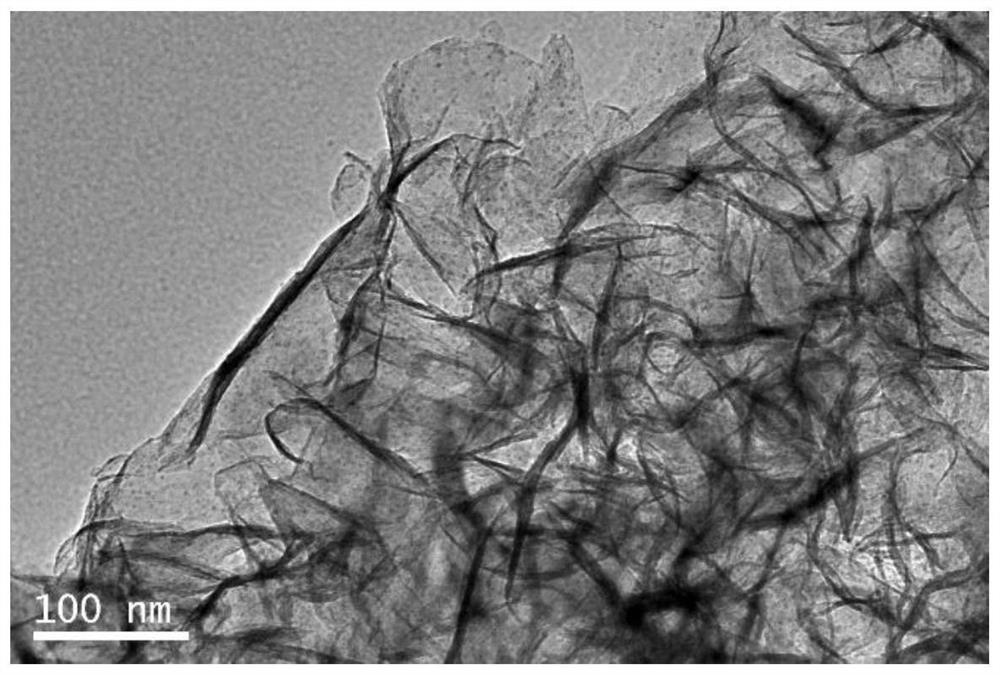

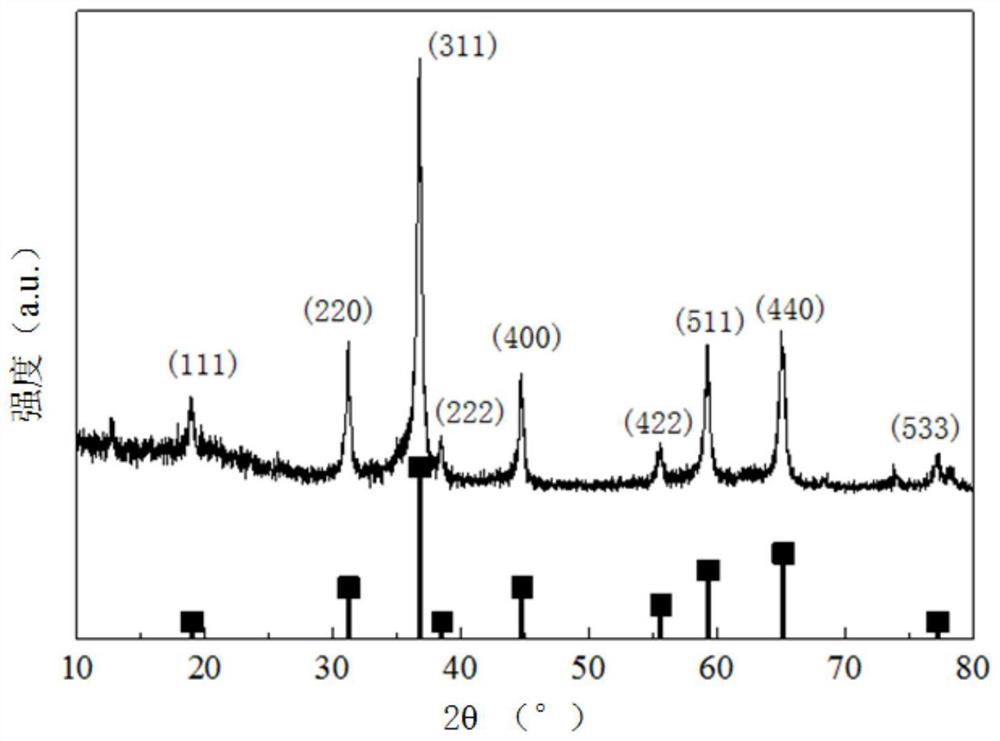

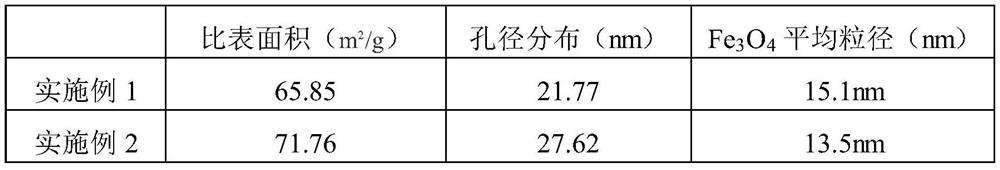

[0030] A preparation method of magnetic CNx catalyst, comprising the steps of:

[0031](1) Dissolve 10g of SMA in 20mL of deionized water, then add 3mL of concentrated ammonia water with a concentration of 25wt%, stir and heat, and control the heating temperature at 80°C for 3h to obtain a mixed solution A; mix 2g of Fe(NO 3 ) 3 Dissolve in 10mL deionized water to form iron salt solution;

[0032] Mix the mixed solution A with the iron salt solution, stir and react at 30° C. for 1 h, and the stirring speed is 500 rpm, to obtain the mixed solution B;

[0033] (2) The pH value of the mixed solution B is adjusted to 3 to 4 by nitric acid with a mass concentration of 10%, the nitric acid titration rate is 10mL / min, and the stirring reaction is continued for 12 hours to obtain a precipitate, filter, and wash the precipitate several times The precursor was obtained by vacuum drying at 70°C;

[0034] (3) The precursor is placed in the atmosphere furnace, and H 2 / Ar mixed gas, wh...

Embodiment 2

[0038] A preparation method of magnetic CNx catalyst, comprising the steps of:

[0039] (1) Dissolve 10g of SMA in 30mL of deionized water, then add 4mL of concentrated ammonia water with a concentration of 25wt%, stir and heat, and control the heating temperature at 60°C for 3h to obtain a mixed solution A; 3 Dissolve in 10mL deionized water to form iron salt solution;

[0040] Mix the mixed solution A with the iron salt solution, stir and react at 50° C. for 8 hours, and the stirring speed is 1000 rpm, to obtain the mixed solution B;

[0041] (2) Use hydrochloric acid with a mass concentration of 10% to adjust the pH value of the mixed solution B to 3-4, the hydrochloric acid addition rate is 5mL / min, continue to stir and react for 8h, obtain a precipitate, filter, and wash the precipitate several times The precursor was obtained by vacuum drying at 100°C;

[0042] (3) The precursor is placed in the atmosphere furnace, and H 2 / Ar mixed gas, where H 2 The mass concentrat...

Embodiment 3

[0046] A preparation method of magnetic CNx catalyst, comprising the steps of:

[0047] (1) Dissolve 8g of SMA in 20mL of deionized water, then add 5mL of concentrated ammonia water with a concentration of 25wt%, stir and heat, and control the heating temperature at 100°C for 4 hours to obtain a mixed solution A; 3 [Fe(CN) 6 ] was dissolved in 10mL deionized water to form an iron salt solution;

[0048] Mix the mixed solution A with the iron salt solution, stir and react at 100° C. for 1 hour at a stirring speed of 30,000 rpm to obtain the mixed solution B;

[0049] (2) The pH value of the mixed solution B is adjusted to 3 to 4 by nitric acid with a mass concentration of 10%, the nitric acid titration rate is 1mL / min, and the stirring reaction is continued for 4h to obtain a precipitate, filter, and wash the precipitate several times The precursor was obtained by vacuum drying at 100°C;

[0050] (3) The precursor is placed in the atmosphere furnace, and H 2 / Ar mixed gas, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com