Glucose sensor

A technology of glucose sensor and glucose dehydrogenase, which is applied in the field of glucose dehydrogenase composition, can solve the problems of small sensor response current blank value, inability to fully improve storage stability, inability to obtain and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

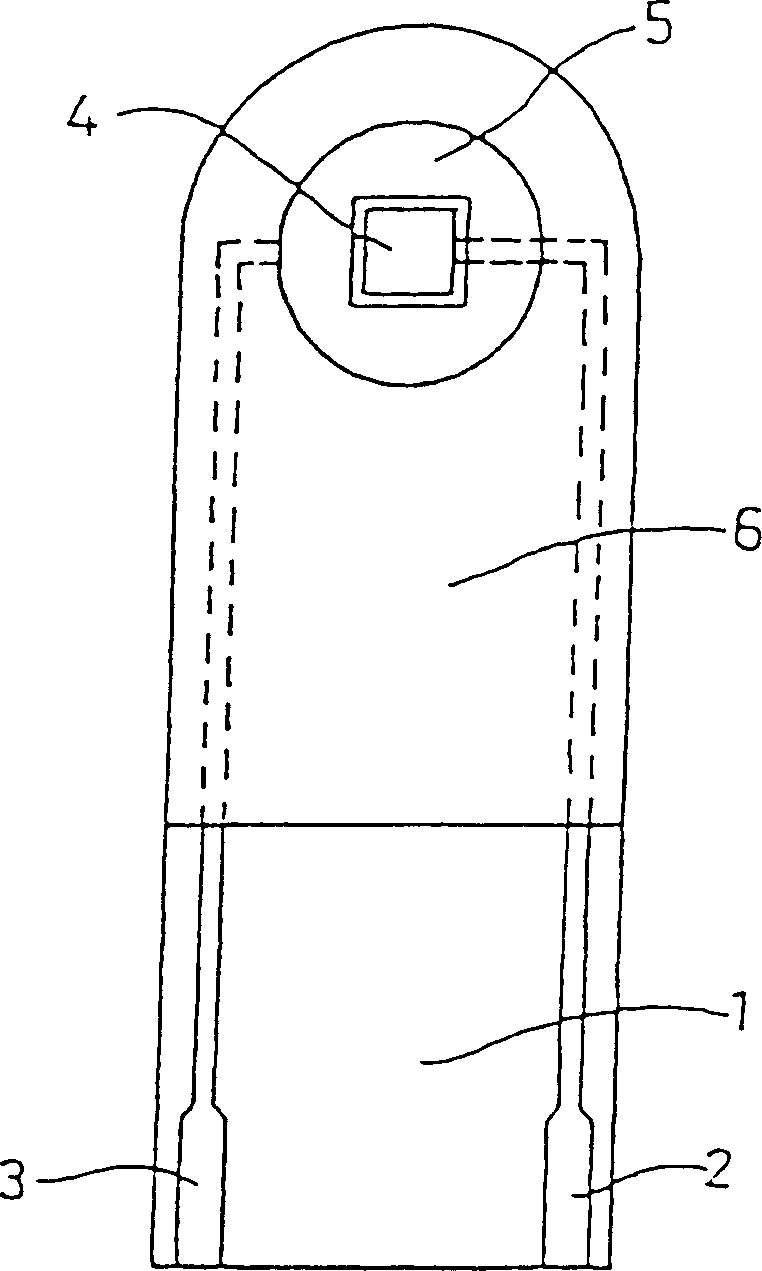

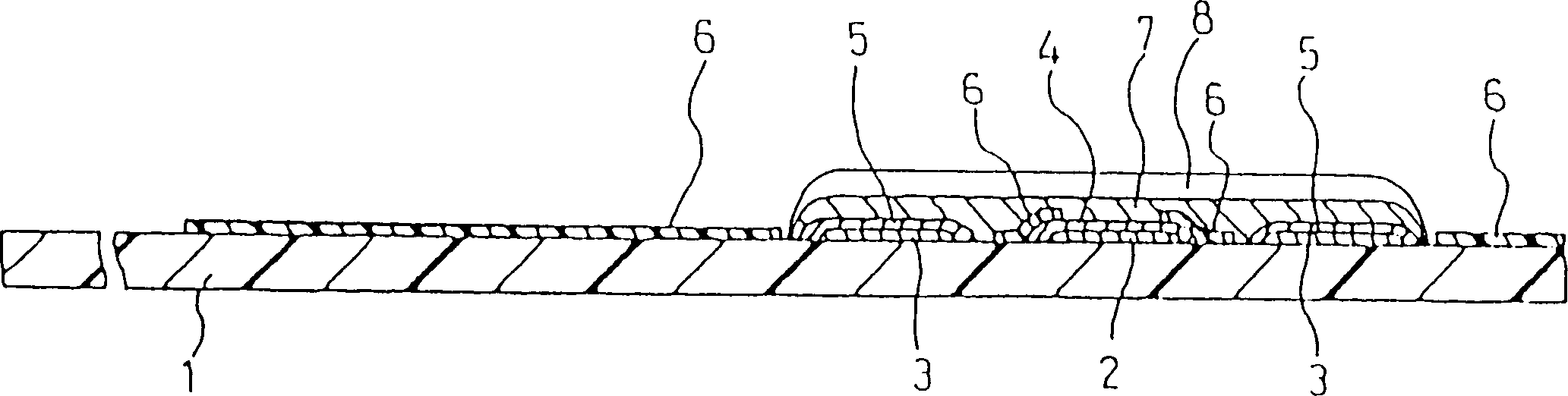

[0065] exist figure 1 0.5 wt% aqueous solution of carboxymethylcellulose sodium salt (hereinafter referred to as "CMC") as a hydrophilic polymer was dropped on the electrode of the substrate 1, and dried in a warm air dryer at 50°C for 10 minutes to form CMC. Layer 7. Then, a mixed solution of 5000 units of PQQ-GDH, 20 μM potassium hydrogen phthalate and 50 μM potassium ferricyanide dissolved in 1 ml of water was dropped on the CMC layer 7, and the reaction layer 8 was formed after drying. In this way, a glucose sensor was fabricated.

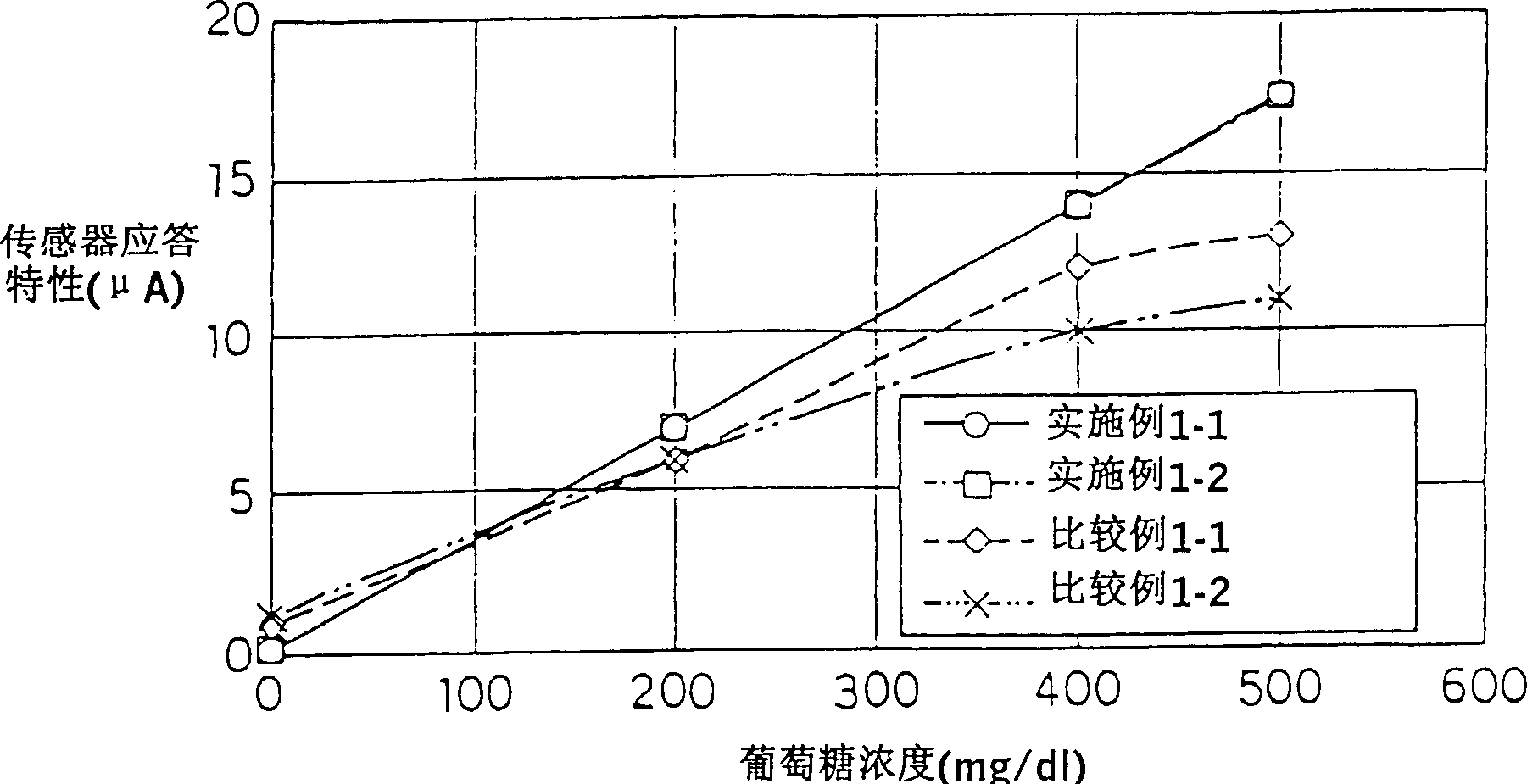

[0066] Then, aqueous glucose solutions of various concentrations were prepared as sample solutions, and the above sample solutions were dropped on the reaction layer 8 . Once the sample solution containing glucose is dropped on the reaction layer, the glucose in the sample is oxidized by PQQ-GDH. At the same time, potassium ferricyanide in the reaction layer is reduced to potassium ferrocyanide.

[0067] After adding the sample solution dro...

Embodiment 2

[0080] Except that the CMC layer 7 was not formed on the electrodes, a glucose sensor was manufactured in the same manner as in Example 1. Then, in the same manner as in Example 1, graphs were drawn of the response characteristics of the sensor immediately after production and after storage for 6 months.

[0081] As a result, there is a certain correlation between the glucose concentration and the current value, which has a good linear relationship. The blank value was also small, and there was almost no difference in response characteristics between the sensor immediately after production and the sensor stored for 6 months, showing good storage stability.

Embodiment 3~10

[0083]In addition to using maleic acid (Example 3), succinic acid (Example 4), triethanolamine hydrochloride (Example 5), sodium dihydrogen citrate (Example 6), dimethylglutaric acid (Example 7), 2-(N-morpholino) ethanesulfonic acid (embodiment 8), three (hydroxymethyl) glycine (embodiment 9) or tris (hydroxymethyl) aminomethane (embodiment 10) replace benzene Except for potassium hydrogen diformate, the other operations were the same as in Example 1 to prepare a glucose sensor, and then draw the response characteristic diagram of the sensor just after fabrication and after storage for 6 months. The response characteristic diagram is as follows Figure 4 ~ Figure 11 shown.

[0084] from Figure 4 ~ Figure 11 It can be seen that the blank value of the fabricated sensor is very small, and there is a certain correlation between the concentration and the current value. Furthermore, the responsiveness was high and a good linear relationship was shown. In addition, there was alm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com