Graphene-magnetic nanowire probe and preparation method thereof

A graphene and nanowire array technology, applied in graphene, nanocarbon, separation methods, etc., can solve the problems of short life, high price, poor stability, etc., and achieve the effects of good binding, simple method and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

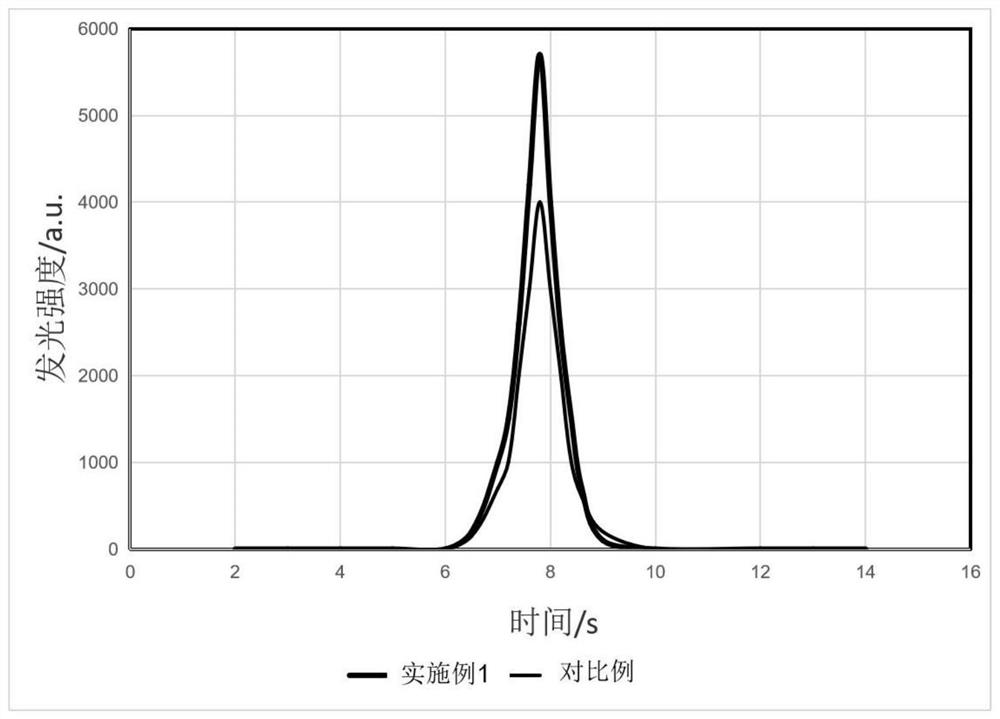

Embodiment 1

[0024] A graphene-Fe3O4 solid-phase microextraction probe, its preparation method is as follows:

[0025] (1) After cleaning and drying the metal wire, hot-dip aluminum coating on the surface of the metal wire, the thickness of the aluminum coating layer is 20um, and then anodize the aluminum coating layer, and after forming nano-scale channels on the aluminum coating layer, clean and dry spare;

[0026] (2) Mix FeCl3, sodium citrate, sodium acetate, and ethylene glycol, stir to dissolve, and disperse evenly by ultrasonic to obtain a sol; the mass ratio of FeCl3, sodium citrate, and sodium acetate is 2:1:4; The volume consumption of ethylene glycol is 30mL / g based on the quality of FeCl3;

[0027] (3) Apply the sol of step (2) on the surface of the metal wire prepared in step (1), and apply ultrasonic vibration for 20 minutes to promote the penetration of the sol into the nanoscale pores, and then immerse it in the sol of step (2) , after being heated to 200°C for 6 hours, t...

Embodiment 2

[0031] A graphene-Fe3O4 solid-phase microextraction probe, its preparation method is as follows:

[0032] (1) After cleaning and drying the metal wire, hot-dip aluminum coating on the surface of the metal wire, the thickness of the aluminum coating layer is 50um, and then anodize the aluminum coating layer, and after forming nano-scale channels on the aluminum coating layer, clean and dry spare;

[0033] (2) Mix FeCl3, sodium citrate, sodium acetate, and ethylene glycol, stir to dissolve, and disperse evenly by ultrasonic to obtain a sol; the mass ratio of FeCl3, sodium citrate, and sodium acetate is 2:1:4; The volume consumption of ethylene glycol is 50mL / g based on the quality of FeCl3;

[0034] (3) Apply the sol of step (2) on the surface of the metal wire prepared in step (1), and apply ultrasonic vibration for 30 minutes to promote the penetration of the sol into the nanoscale pores, and then immerse it in the sol of step (2) , after being heated to 200°C for 10 hours, ...

Embodiment 3

[0038] A graphene-Fe3O4 solid-phase microextraction probe, its preparation method is as follows:

[0039] (1) After cleaning and drying the metal wire, hot-dip aluminum coating on the surface of the metal wire, the thickness of the aluminum coating layer is 5um, and then anodize the aluminum coating layer, and after forming nano-scale channels on the aluminum coating layer, clean and dry spare;

[0040] (2) Mix FeCl3, sodium citrate, sodium acetate, and ethylene glycol, stir to dissolve, and disperse evenly by ultrasonic to obtain a sol; the mass ratio of FeCl3, sodium citrate, and sodium acetate is 2:1:4; The volume consumption of ethylene glycol is 30mL / g based on the quality of FeCl3;

[0041] (3) Apply the sol of step (2) on the surface of the metal wire prepared in step (1), and apply ultrasonic vibration for 10 minutes to promote the penetration of the sol into the nanoscale pores, and then immerse it in the sol of step (2) , after being heated to 200°C for 5 hours, co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com