Preparation method of oxygen-deficient VIB group element oxide quantum dots, prepared quantum dots and application

A family element and oxygen-deficient technology, which is applied in the field of oxygen-deficient oxidized VIB group element quantum dots and its preparation, can solve the problem of few synthesis methods of tungsten oxide and molybdenum oxide quantum dots, difficulties in mass production of VIB group element quantum dots, and harsh synthesis conditions and other problems, to achieve the effect of excellent performance, novel synthesis method and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

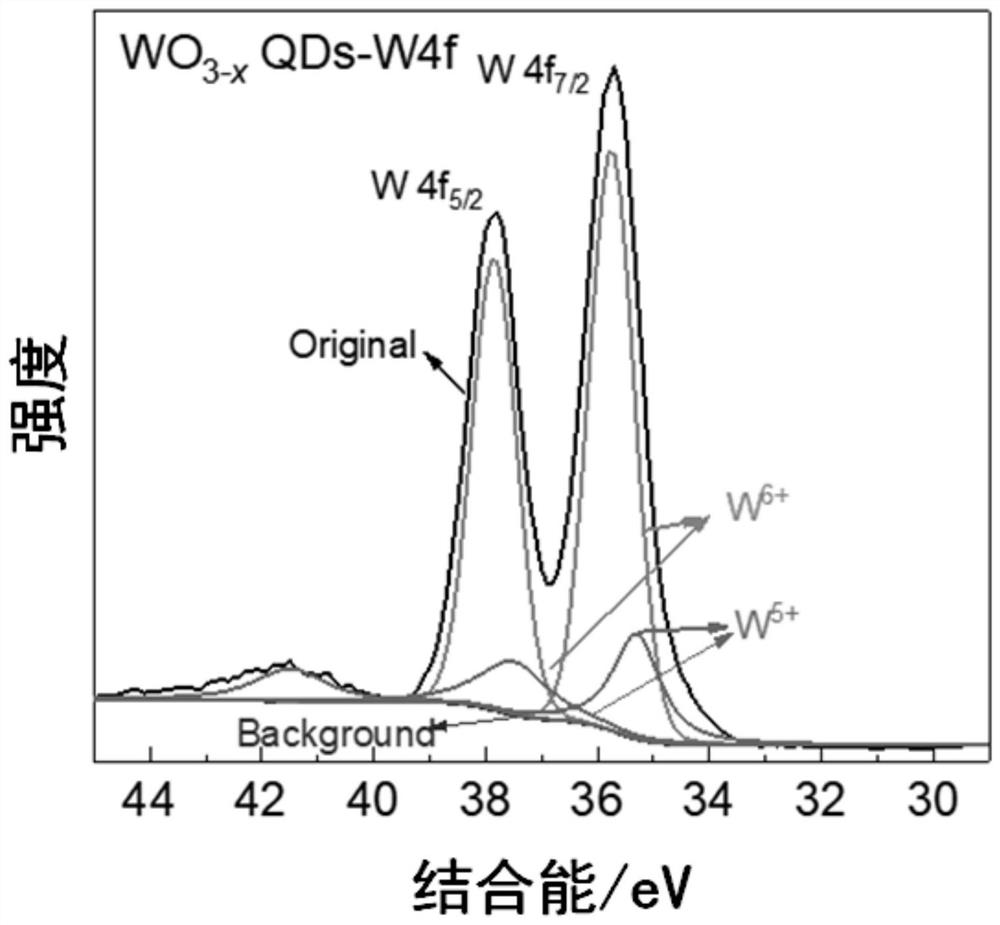

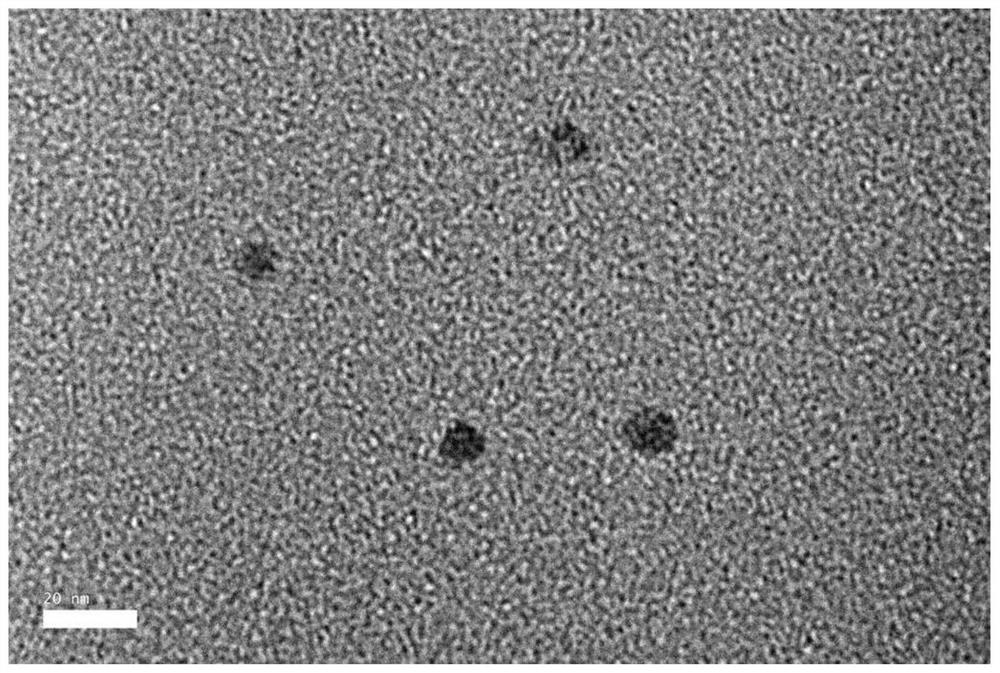

[0040] An oxygen-deficient tungsten oxide quantum dot (WO 3-x QDs) preparation method, comprising the following steps:

[0041] S1. Mix 10 mg of tungsten disulfide powder with 50 mL of dimethylformamide to form a mixed solution; S2. Sonicate the mixed solution for 80 minutes at a power of 240W to obtain a black solution; S3. Stir the black solution at 160°C and 700rpm Reflux for 2 hours under conditions to obtain a reflux solution; S4, centrifuge the reflux solution at 1000 rpm for 30 minutes to obtain a supernatant; S5, heat the supernatant at 60° C. for 5 hours under vacuum conditions, and wash the precipitate with ultrapure water; S6, drying the precipitate by rotary evaporation at 60°C to obtain an oxygen-deficient tungsten oxide quantum dot solid; S7, dispersing the solid in ultrapure water to obtain an oxygen-deficient tungsten oxide quantum dot solution.

Embodiment 2

[0043] An oxygen-deficient tungsten oxide quantum dot (WO 3-xThe preparation method of QDs) comprises the following steps: S1, mixing 20 mg of tungsten disulfide powder with 50 mL of dimethylformamide to form a mixed solution; S2, ultrasonicating the mixed solution for 120 minutes at a power of 240W to obtain a black solution; S3 1. Reflux the black solution at 140°C and 700rpm for 3 hours to obtain a reflux solution; S4. Centrifuge the reflux solution at 2000rpm for 30 minutes to obtain a supernatant; S5. Heat the supernatant at 70°C under vacuum 2 hours, and wash the precipitate with ultrapure water; S6, dry the precipitate by rotary evaporation at 80°C to obtain an oxygen-deficient tungsten oxide quantum dot solid; S7, disperse the solid in ultrapure water to obtain an oxygen-deficient tungsten oxide quantum dot solution.

Embodiment 3

[0045] An oxygen-deficient tungsten oxide quantum dot (WO 3-x The preparation method of QDs) comprises the following steps: S1, mixing 30 mg of tungsten disulfide powder with 50 mL of dimethylformamide to form a mixed solution; S2, supercharging the mixed solution for 160 minutes at a power of 240W to obtain a black solution; S3 1. Reflux the black solution for 4 hours at 140°C and 700rpm stirring to obtain a reflux solution; S4. Centrifuge the reflux solution at 3000rpm for 30min to obtain a supernatant; S5. Heat the supernatant at 60°C under vacuum 3 hours, and wash the precipitate with ultrapure water; S6, dry the precipitate by rotary evaporation at 60°C to obtain an oxygen-deficient tungsten oxide quantum dot solid; S7, disperse the solid in ultrapure water to obtain an oxygen-deficient tungsten oxide quantum dot solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com