Slow-release type blended fertilizer

A blended fertilizer and slow-release technology, applied in the direction of nitrogen fertilizer, potassium fertilizer, phosphorus fertilizer, etc., can solve the problems of soil aggregate structure damage, soil hardening, soil compaction, etc., and achieve the effect of promoting activity, increasing activity and preventing soil compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

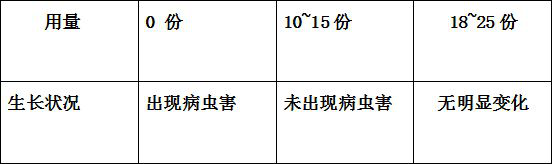

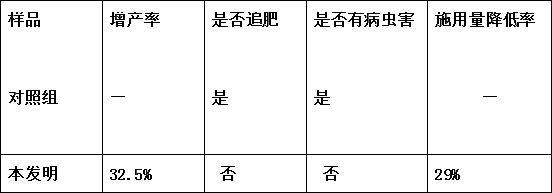

Method used

Image

Examples

Embodiment 1

[0039] A slow-release blending fertilizer, which is composed of the following raw materials in parts by weight: 5 parts of monoammonium phosphate, 7 parts of potassium sulfate, 20 parts of coated urea, 6 parts of borax, 1 part of amino acid chelated zinc, 1 part of 3,4-dimethylpyrazole phosphate, 10 parts of talc, 2 parts of attapulgite, 3 parts of straw, 2 parts of soybean meal, 2 parts of vinasse, 3 parts of actinomycetes, 2 parts of forchlorfenuron.

[0040] A method for preparing slow-release blended fertilizer, which is characterized in that:

[0041] (1) Weigh out monoammonium phosphate, potassium sulfate, borax, amino acid chelated zinc and attapulgite in proportion, crush, sieving, and set aside;

[0042] (2) Stir the biological inoculum, straw, soybean meal and distiller's grains in proportion and place in a closed container, ferment at 40°C for 3 days, for use;

[0043] (3) Mix polyvinyl alcohol, polyurethane, and cellulose, then add them to an organic solvent, stir continuo...

Embodiment 2

[0046] A slow-release blending fertilizer, which is composed of the following raw materials in parts by weight: 25 parts of monoammonium phosphate, 35 parts of potassium sulfate, 70 parts of coated urea, 20 parts of borax, 10 parts of amino acid chelated zinc, 10 parts of 3,5-dimethylpyrazole, 20 parts of sodium dodecylbenzene sulfonate, 18 parts of attapulgite, 11 parts of straw, 15 parts of soybean meal, 12 parts of vinasse, 17 parts of actinomycetes, forchlorfenuron 14 servings.

[0047] A method for preparing slow-release blended fertilizer, which is characterized in that:

[0048] (1) Weigh out monoammonium phosphate, potassium sulfate, borax, amino acid chelated zinc and attapulgite in proportion, crush, sieving, and set aside;

[0049] (2) Stir the biological inoculum, straw, soybean meal and distiller's grains in proportion and place them in an airtight container, and ferment at 80°C for 9 days before use;

[0050] (3) Mix polyvinyl alcohol, polyurethane, and cellulose, then ...

Embodiment 3

[0053] A slow-release blending fertilizer, which is composed of the following raw materials in parts by weight: 7 parts of monoammonium phosphate, 10 parts of potassium sulfate, 22 parts of coated urea, 7 parts of borax, 2 parts of amino acid chelated zinc, 2 parts of dicyandiamide, 11 parts of sodium lauryl sulfate, 3 parts of attapulgite, 4 parts of straw, 3 parts of soybean meal, 3 parts of distiller's grains, 4 parts of silicate bacteria, and 3 parts of penicillin.

[0054] A method for preparing slow-release blended fertilizer, which is characterized in that:

[0055] (1) Weigh out monoammonium phosphate, potassium sulfate, borax, amino acid chelated zinc and attapulgite in proportion, crush, sieving, and set aside;

[0056] (2) Stir the biological inoculants, straw, soybean meal and distiller's grains in proportion, place them in an airtight container, and ferment at 50°C for 6 days before use;

[0057] (3) Mix polyvinyl alcohol, polyurethane, and cellulose, then add them to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com