A preparation method of tipping base paper for flexographic printing cigarettes

A technology for tipping base paper and printing cigarettes, which is applied in chemical instruments and methods, tobacco, papermaking, etc., can solve the problems of cigarette tipping paper, such as poor effect of tar reduction and harm reduction, reduction of paper porosity, and unfavorable human health. Achieve the effect of good flue gas moist feeling, improve safety and sanitation, and good flocculation and retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

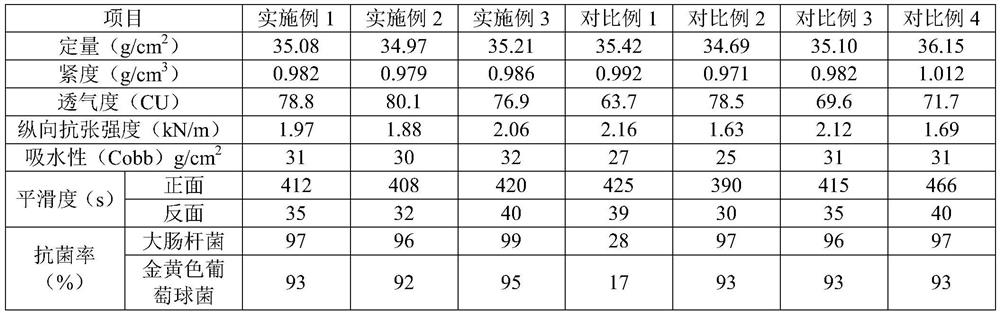

Examples

Embodiment 1

[0032] A preparation method for flexographic printing cigarette tipping base paper, comprising the steps of:

[0033] (1) Pulping: pulping after beating to obtain pulp, the pulp includes 65% bleached hardwood pulp and 35% bleached natural softwood pulp, the beating degree of bleached hardwood pulp is 25°SR, and the wet weight is 3.0g , the beating degree of bleached natural softwood pulp is 75°SR, and the wet weight is 11g;

[0034] (2) Slurry modification: add betaine of 15% of slurry quality to the slurry, and then add polyepichlorohydrin-dimethylamine modified filler of 55% of slurry quality, 1.2% of PAE wet strength agent (solid content 15%), 1.5% cationic starch and 1.5% AKD (solid content 10%), after being stirred evenly, the modified slurry is obtained;

[0035] The polyepichlorohydrin-dimethylamine modified filler includes one or both of modified light calcium carbonate and modified titanium dioxide with a mass ratio of 5:1, and its preparation method is:

[0036] A)...

Embodiment 2

[0041] A preparation method for flexographic printing cigarette tipping base paper, comprising the steps of:

[0042] (1) Pulping: pulping after beating to obtain pulp, the pulp includes 60% bleached hardwood pulp and 40% bleached natural softwood pulp, the beating degree of bleached hardwood pulp is 20 ° SR, and the wet weight is 4.0g , the beating degree of bleached natural softwood pulp is 70°SR, and the wet weight is 12g;

[0043] (2) Slurry modification: add 10% betaine of slurry quality to the slurry, and then add polyepichlorohydrin-dimethylamine modified filler of 50% slurry quality, 1% of PAE wet strength agent (solid content 12%), 1% cationic starch and 2% AKD (solid content 10%), after being stirred evenly, the modified slurry is obtained;

[0044] Polyepichlorohydrin-dimethylamine modified filler is modified light calcium carbonate, and its preparation method is:

[0045] A) Disperse light calcium carbonate in xylene, add γ-chloropropyltrimethoxysilane, heat and ...

Embodiment 3

[0050] A preparation method for flexographic printing cigarette tipping base paper, comprising the steps of:

[0051] (1) Pulping: pulping after beating to obtain pulp, which includes 70% bleached hardwood pulp and 30% bleached natural softwood pulp, the beating degree of bleached hardwood pulp is 30°SR, and the wet weight is 2.0g , the beating degree of bleached natural softwood pulp is 80°SR, and the wet weight is 10g;

[0052] (2) Slurry modification: add betaine of 20% of slurry quality to the slurry, stir and react for 30min and then add polyepichlorohydrin-dimethylamine modified filler of 60% of slurry quality, 1.5% of PAE wet strength agent (solid content 15%), 2% cationic starch and 1% AKD (solid content 12%), after being stirred evenly, the modified slurry is obtained;

[0053] Polyepichlorohydrin-dimethylamine modified filler is modified light calcium carbonate, and its preparation method is:

[0054] A) Disperse light calcium carbonate in xylene, add γ-chloropropy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com