High-water-absorption film composite material and preparation method thereof

A thin film composite material, high water absorption technology, applied in flat products, other household utensils, applications, etc., can solve the problems of airtightness, large space and usage, discomfort, etc., achieve high elongation, thickness reduction, Guaranteed stability and spillover effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

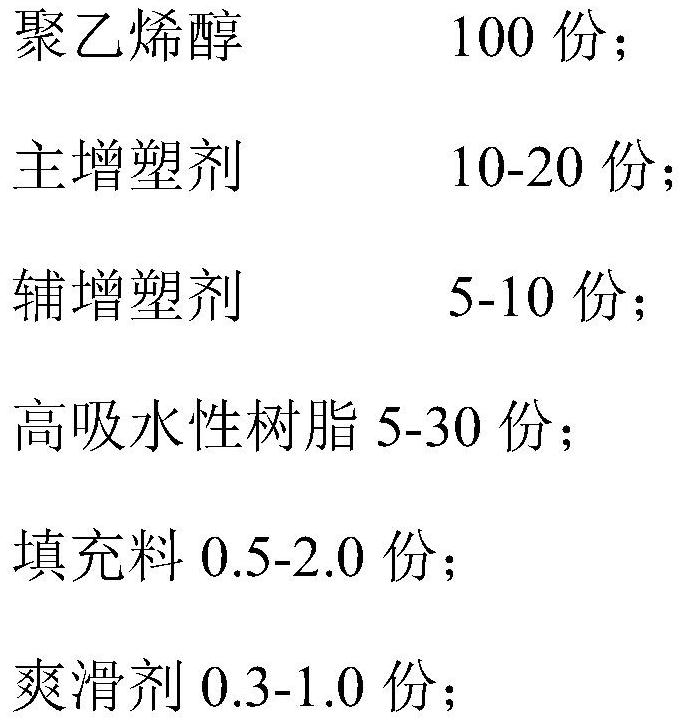

[0049] A method for preparing a superabsorbent film composite material, at least comprising the following components in parts by weight:

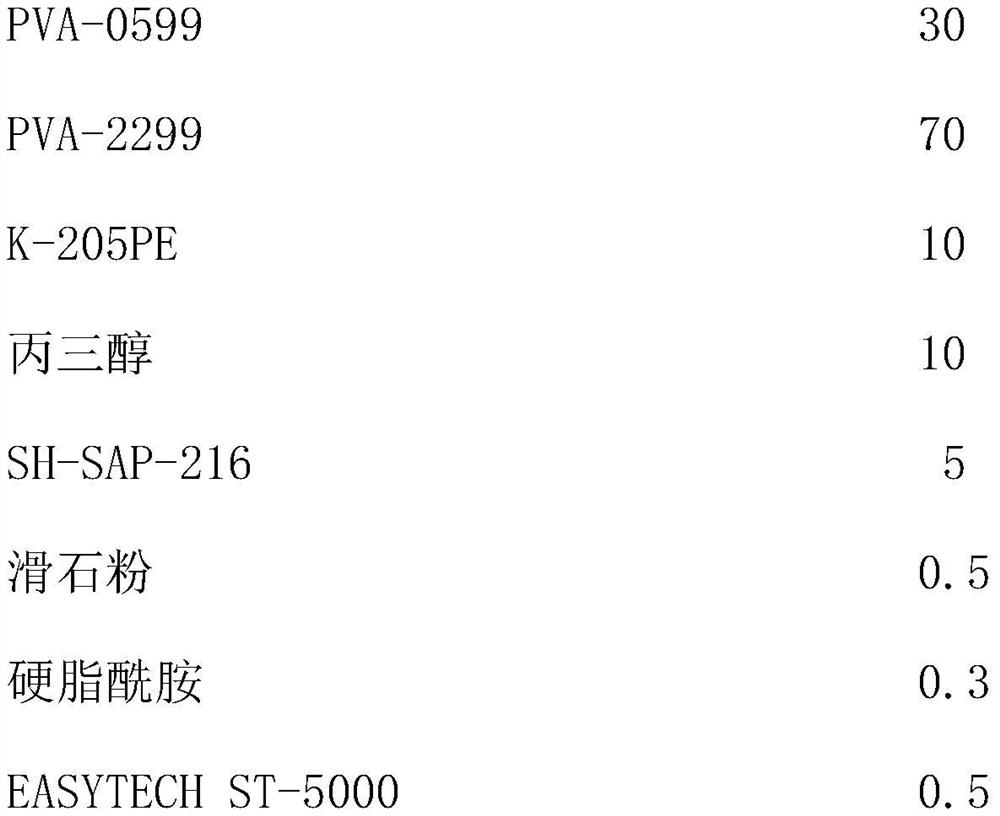

[0050] Weight (parts)

[0051]

[0052] After the above-mentioned components are measured separately, first add polyvinyl alcohol PVA, talc powder, stearamide, and EASYTECH ST-5000 into the high-speed mixer, start stirring, and stir at a low speed of 200 rpm for 5 minutes; open a high-speed 1200 After stirring for 20 minutes at rpm, add K-205PE and glycerol, continue stirring at high speed (1200 rpm) for 30 minutes, turn to low speed at 100 rpm, add SH-SAP-216, continue Stir for 15 minutes, discharge and set aside.

[0053] After the raw materials of the above components are mixed evenly, they are added to a twin-screw blending extrusion granulator for extrusion granulation. The extruder is divided into 10 zones for temperature control extrusion granulation: 100 / 120 / 140 / 150 / 160 / 170 / 180 / 180 / 170 / 160°C; the die is filtered with a 120-mes...

Embodiment 2

[0059] A method for preparing a superabsorbent film composite material, at least comprising the following components in parts by weight:

[0060] Weight (parts)

[0061]

[0062] After the above-mentioned components are measured separately, first add polyvinyl alcohol PVA, light calcium carbonate, oleamide, and EASYTECHST-5020 into the high-speed stirring mixer, start stirring, and stir at a low speed of 300 rpm for 15 minutes; turn on a high speed of 1500 After stirring for 30 minutes at rpm, add Na-203PE and ethylene glycol, continue stirring at high speed (1500 rpm) for 15 minutes, turn to low speed at 200 rpm, add SK273, and continue stirring for 30 minutes , the material is ready for use.

[0063] After the raw materials of the above components are mixed evenly, they are added to a twin-screw blending extrusion granulator for extrusion granulation. The extruder is divided into 10 zones for temperature control extrusion granulation: 100 / 120 / 140 / 150 / 160 / 170 / 180 / 180 / 17...

Embodiment 3

[0069] A method for preparing a superabsorbent film composite material, at least comprising the following components in parts by weight:

[0070] Weight (parts)

[0071]

[0072] After the above-mentioned components are measured separately, first add polyvinyl alcohol PVA, white carbon black, erucamide, and EASYTECH ST-5030 into the high-speed stirring mixer, start stirring, and stir at a low speed of 250 rpm for 10 minutes; After stirring at 1300 rpm for 25 minutes, add Na-208PE and polyethylene glycol-400, continue to stir at high speed (1300 rpm) for 20 minutes, turn to low speed at 150 rpm, add SP601, Continue to stir for 20 minutes, discharge and set aside.

[0073] After the raw materials of the above components are mixed evenly, they are added to a twin-screw blending extrusion granulator for extrusion granulation. The extruder is divided into 10 zones for temperature control extrusion granulation: 100 / 120 / 140 / 150 / 160 / 170 / 180 / 180 / 170 / 160°C; the die is filtered wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com