Preparation method of ternary material coated with orthosilicate positive electrode material

A positive electrode material, ternary material technology, applied in positive electrode, chemical instruments and methods, manganate/permanganate, etc., can solve the problem of extensive input method of additive input, limit the actual performance of coating material, and rarely. Considering problems such as joint processing, it can achieve the effect of improving the high cost of wet method, improving surface active sites, and easy industrialization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

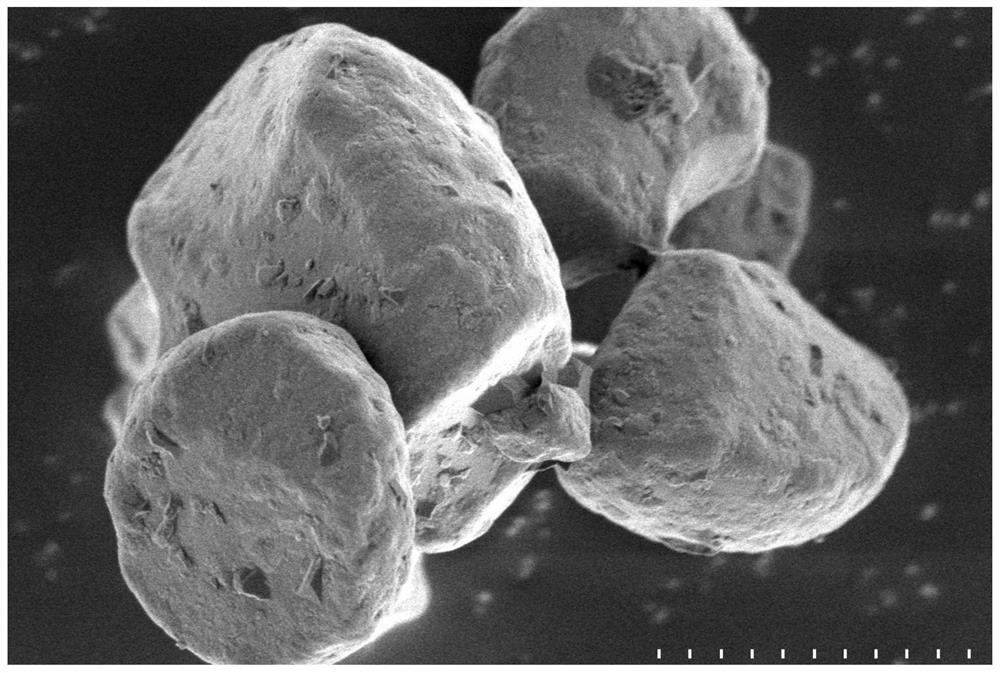

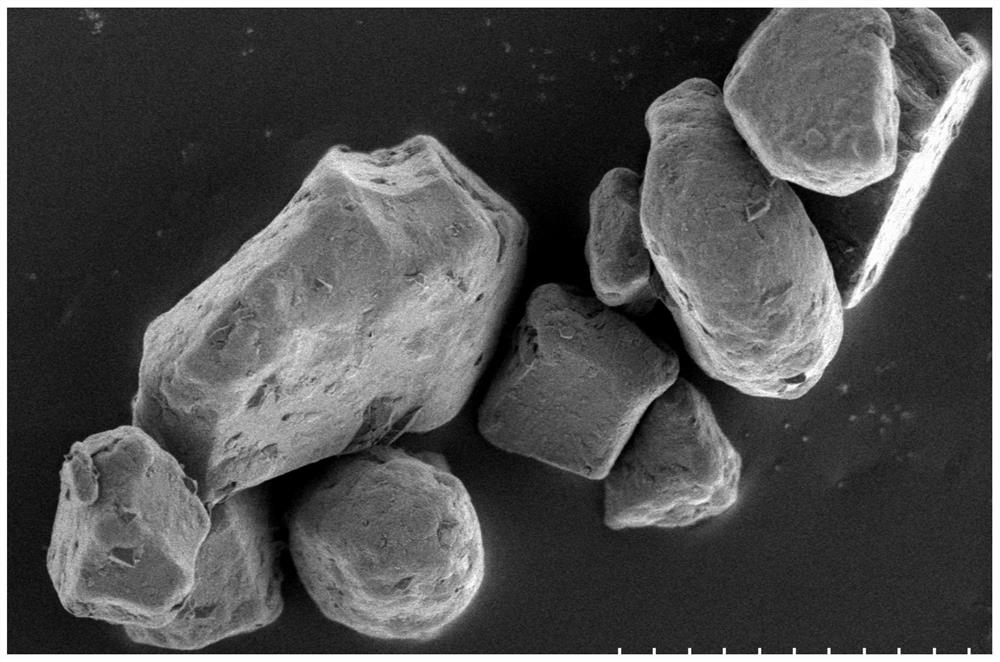

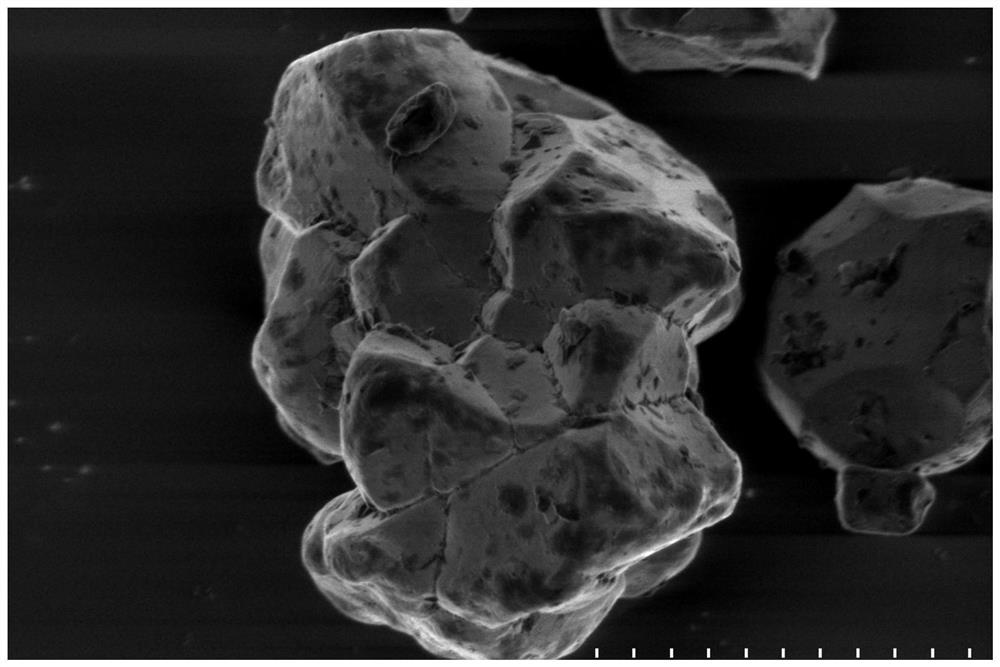

Image

Examples

Embodiment 1

[0039] Dissolve nickel salt, cobalt salt, and manganese salt in water respectively, mix according to the molar ratio of 6:2:2, and adopt the method of co-precipitation to obtain the hydroxide containing three metal salts; according to the molar ratio of lithium metal Li:M 总 = 1.05, the lithium salt is mixed with the precursor, sintered and pulverized to obtain the corresponding ternary cathode material, which is designated as sample 1. Sample 1 was tested for the residual lithium content on the surface, and the residual lithium content and composition information were accurately determined. According to the molar ratio Li: (Si+M) = 0.8:1, add lithium source and additives, the particle size of the additives is 500nm, fluidized mixing for 30min, press at 0.10MPa for tableting, sintering (SJ2) temperature is 600°C , denoted as sample 2. Sample 2 was tested for surface residual lithium and additive (Si+M) content, and the residual lithium content and composition information were ...

Embodiment 2

[0053] Dissolve nickel salt, cobalt salt, and manganese salt in water respectively, mix according to the molar ratio of 6:2:2, and adopt the method of co-precipitation to obtain the hydroxide containing three metal salts; according to the molar ratio of lithium metal Li:M 总 = 1.05, the lithium salt is mixed with the precursor, sintered and pulverized to obtain the corresponding ternary cathode material, which is designated as sample 21. Sample 21 was tested for the residual lithium content on the surface, and the residual lithium content and composition information were accurately determined. According to the molar ratio Li:(Si+M)=0.6:1, add lithium source and additives, the particle size of the additives is 800nm, fluidized mixing for 30min, press at 0.10MPa for tableting, sintering (SJ2) temperature is 600℃ , denoted as sample 22. Sample 22 was tested for surface residual lithium and additive (Si+M) content, and the residual lithium content and composition information were ...

Embodiment 3

[0055] Dissolve nickel salt, cobalt salt, and manganese salt in water respectively, mix according to the molar ratio of 6:2:2, and adopt the method of co-precipitation to obtain the hydroxide containing three metal salts; according to the molar ratio of lithium metal Li:M 总= 1.05, the lithium salt is mixed with the precursor, sintered and pulverized to obtain the corresponding ternary cathode material, which is designated as sample 31. Sample 31 was tested for the residual lithium content on the surface, and the residual lithium content and composition information were accurately determined. According to the molar ratio Li:(Si+M)=0.5:1, add lithium source and additives, the particle size of additives is 500nm, fluidized mixing for 30min, press at 0.10MPa for tableting, sintering (SJ2) temperature is 600℃ , denoted as sample 32. Sample 32 was tested for surface residual lithium and additive (Si+M) content, and the residual lithium content and composition information were accur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com