System for realizing high-efficient low-NOx mixed combustion of gasification carbon residues in cyclone furnace

A technology of cyclone furnace and residual carbon, which is applied in the transportation of non-flammable liquid/gas, combustion of various fuels, and furnaces. Volatile content and other issues, to achieve the effect of improving the utilization rate of water resources, improving the utilization rate of waste heat, and ensuring the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

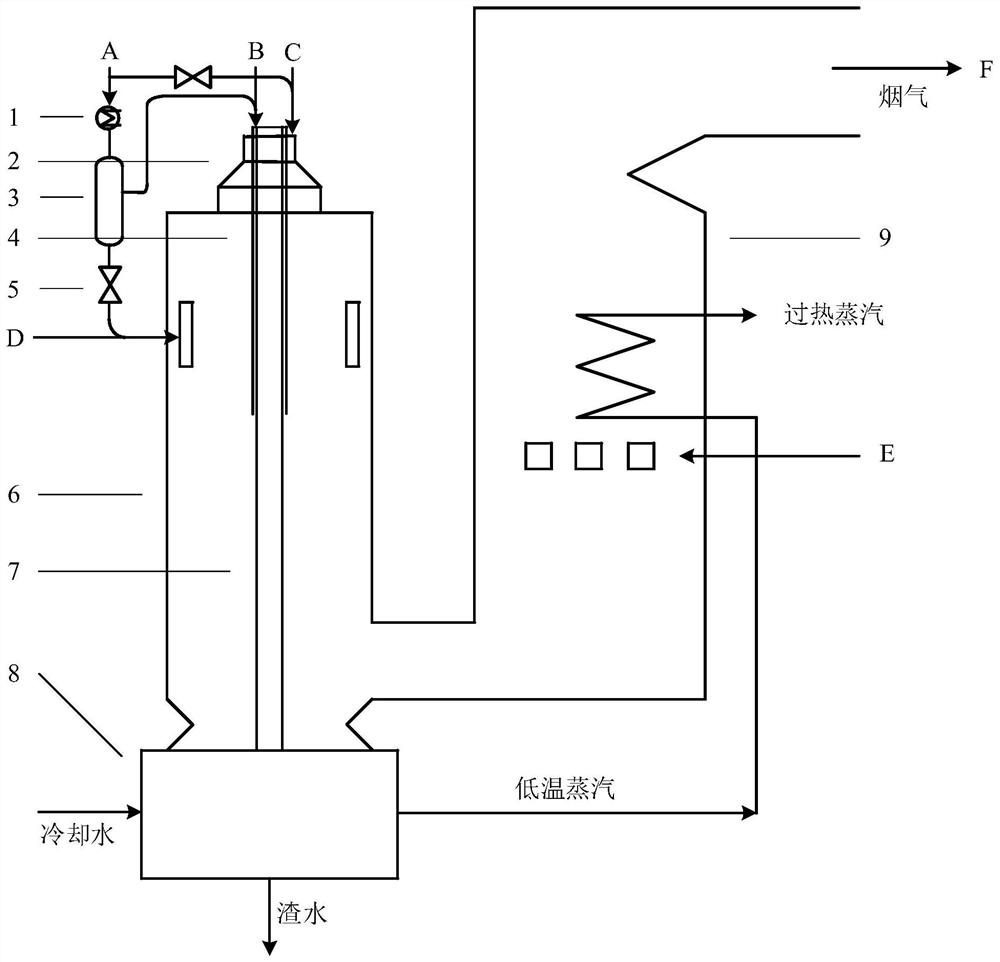

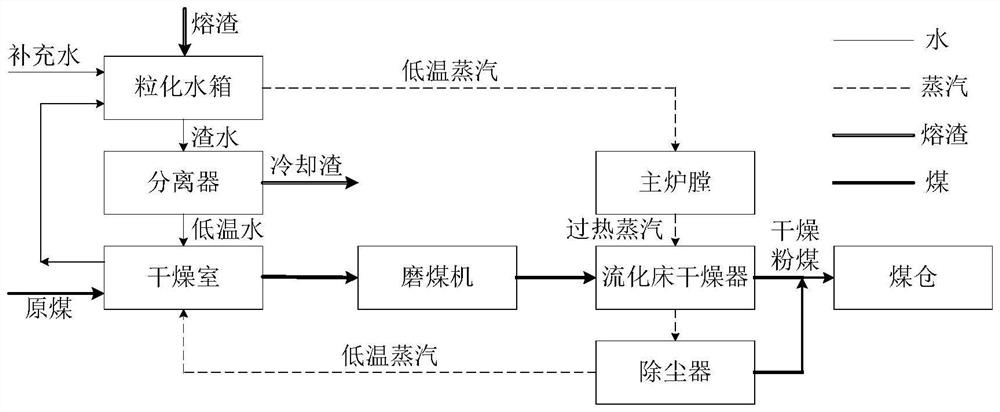

[0028] Such as figure 1 and figure 2 As shown, a kind of cyclone furnace provided by the invention has high efficiency and low NO x A system for blending and burning gasified residual carbon, including air compressor 1, burner 2, air film separator 3, central powder feeding casing 4, flow valve 5, cyclone 6, central water-cooled tube cluster 7, secondary combustion Chamber 9 and liquid slag waste heat utilization system; cyclone furnace liquid slag waste heat utilization system includes granulation water tank 8, separator, drying chamber, coal mill, fluidized bed dryer, dust collector and coal bunker.

[0029] Wherein, the outlet of the air compressor 1 is connected to the inlet of the air membrane separator 3, the air outlet of the air membrane separator 3 with a low oxygen concentration is connected to the secondary air inlet D of the cyclone, and the outlet of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com