Preparation method of low-rank coal-based porous carbon and application of low-rank coal-based porous carbon in supercapacitor

A low-rank coal and porous carbon technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, can solve the problems affecting the application range of supercapacitors, complicated processes, and high preparation costs, and can promote the application range and preparation method. Simple and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

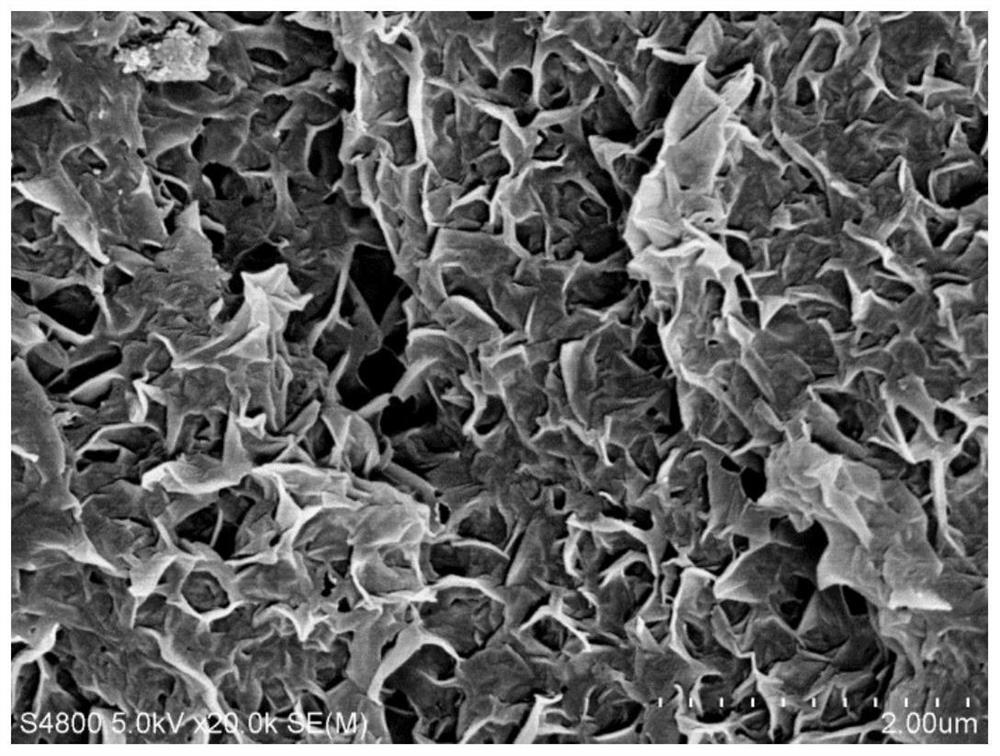

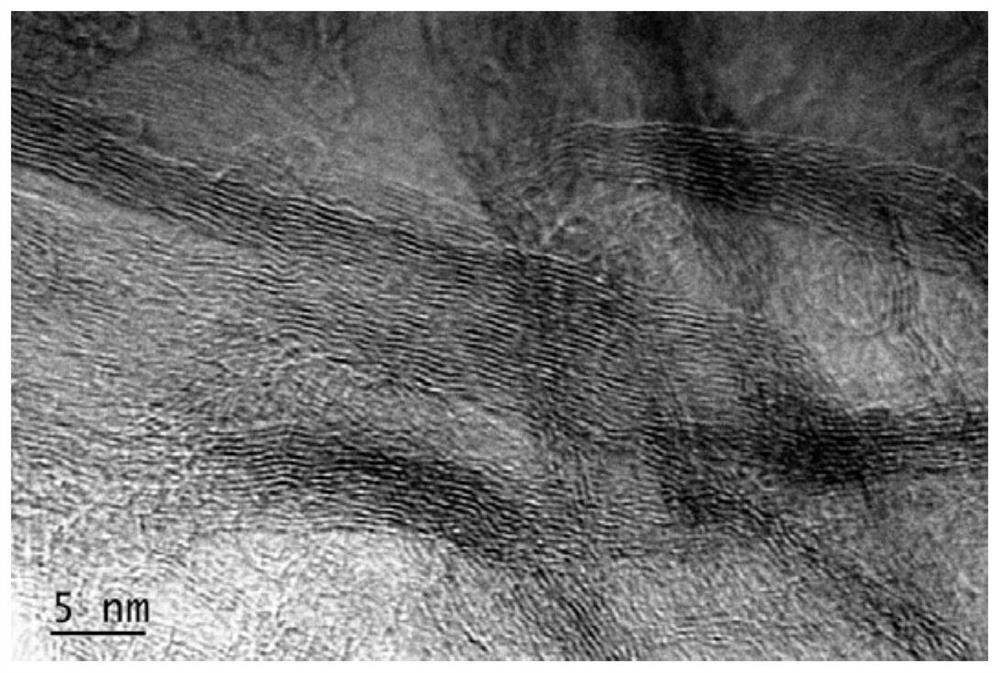

[0026] The low-cost low-rank coal-based porous carbon preparation method of this embodiment is carried out according to the following steps:

[0027] 1. Raw material refinement

[0028] Crushing, grinding, sieving and drying Zhundong subbituminous coal powder in sequence to obtain 80-100 mesh fine coal powder;

[0029] 2. Preparation of the mixture

[0030] mixing fine coal powder with potassium carbonate by liquid phase impregnation to obtain a mixture;

[0031] The liquid-phase impregnation process is as follows: potassium carbonate is dissolved in water to obtain a potassium carbonate solution, 3g of pulverized coal is mixed with the potassium carbonate solution and placed in a mixer to stir evenly, and the mixture is obtained after drying; the drying temperature is 80°C; the speed of the mixer is 300r / min;

[0032] The mass ratio of described pulverized coal and salt of wormwood is 1:3;

[0033] 3. High temperature activation

[0034] Put the mixture in step 2 in the ...

Embodiment 2

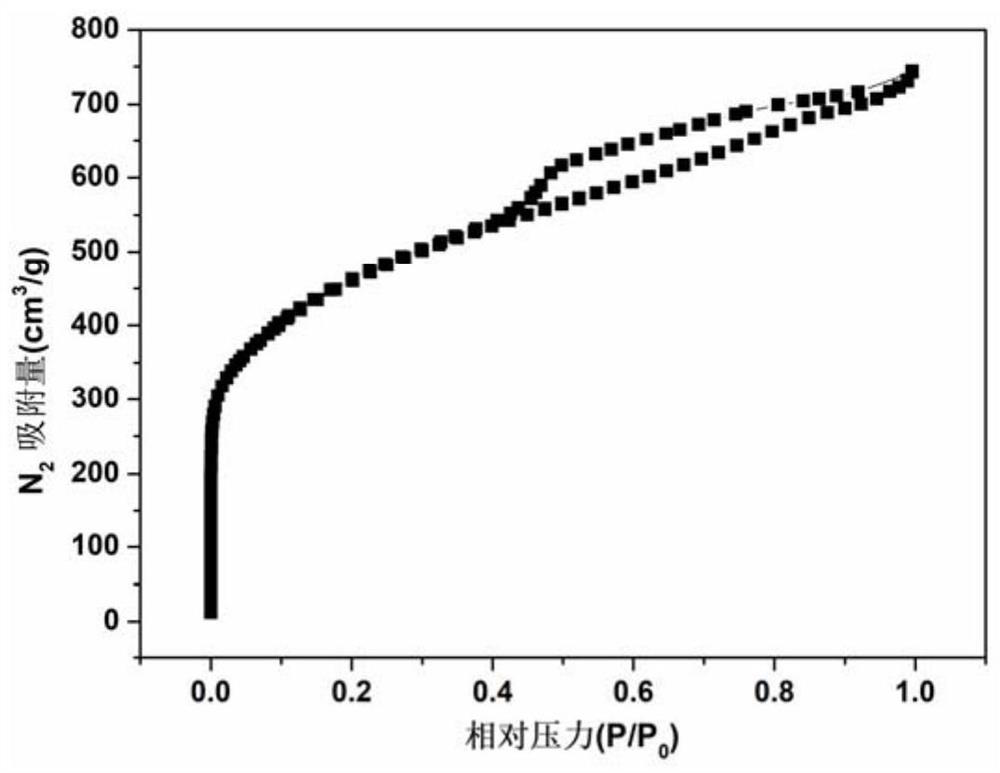

[0044] The low-order coal-based porous carbon obtained in Example 1 is used to prepare a supercapacitor, specifically,

[0045] Electrode preparation: In absolute ethanol, according to the mass ratio of 8:1:1, the selected coal-based porous carbon, conductive carbon black (Super P) and 60wt.% polytetrafluoroethylene emulsion (PTFE) were ground to form a uniform film , dried in a vacuum oven (the drying temperature is 120° C., and the drying time is 12 hours) for later use. Take 2mg of film each time for the preparation of a single pole piece, with an area of about 1cm 2 .

[0046] Symmetrical supercapacitor assembly process: select two pole pieces of the same quality, press them on the sheared nickel foam current collector with a diameter of 1.2cm, and dry them in a vacuum oven (120°C for 12h) as positive and negative electrodes . Use 1mol / LTEA BF4-PC as the electrolyte to assemble an organic capacitor, cut a glass fiber film (model: Whatman) with a diameter of 1.6cm as a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com